13

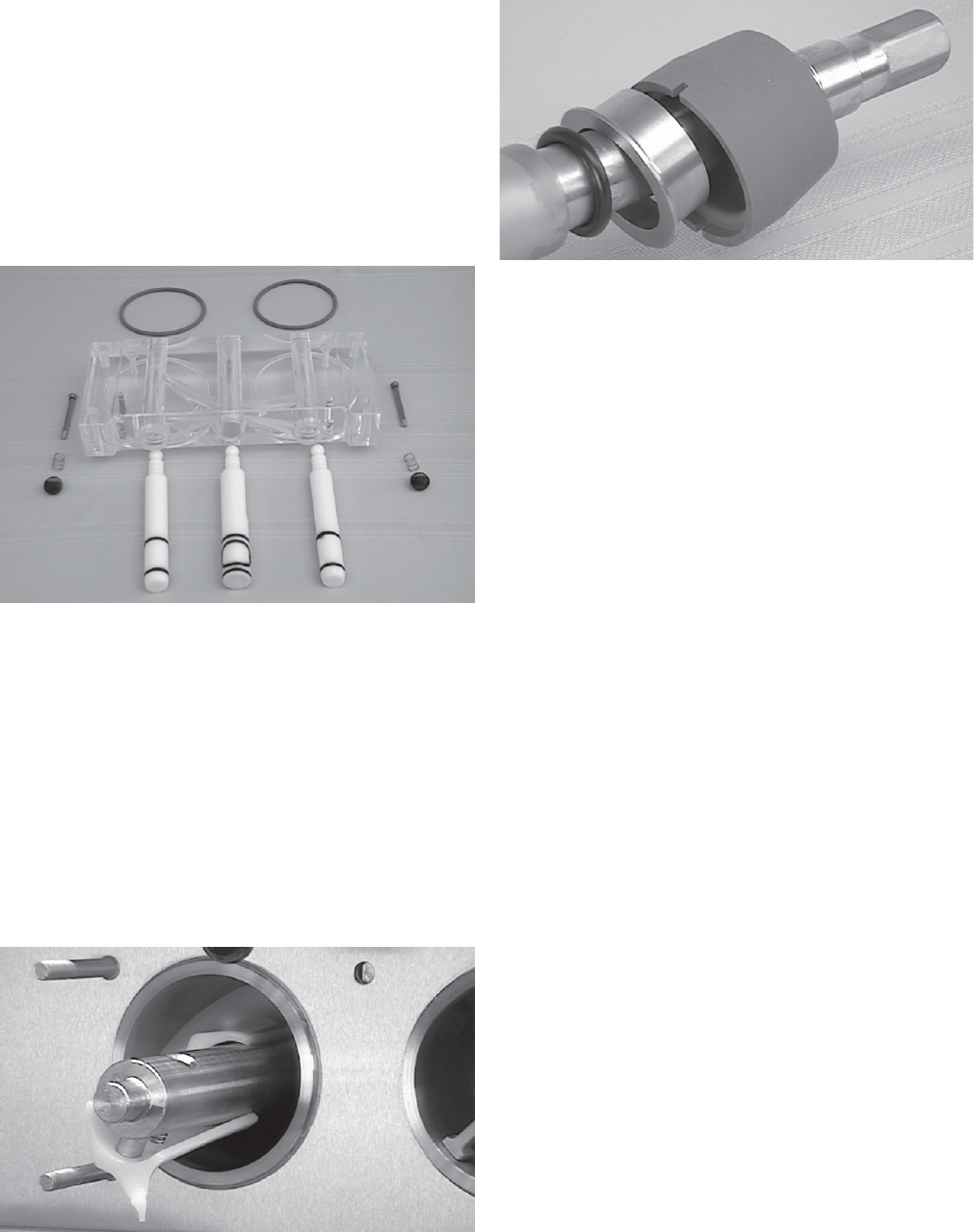

A. Disassembly Of Front Door

1. Remove the front door by turning off the circular

knobs and then pulling the front door off the studs.

2. Remove the air bleed valve by unscrewing the knob

while holding the valve stem from behind. Remove

the compression spring and push air bleed valve

through the rear of the front door.

3. Remove the spigot through the bottom of the front

door (see Figure 13). Remove all O-rings from

spigots and air bleed valve.

B. Disassembly Of Auger

1. Remove the front auger support by pulling it

straight out of the freezer barrel.

Figure 13. Front Door Disassembly

Figure 15. Rear Seal Removal

2. Remove the plastic bearing from the front auger

support.

3. Remove the auger by pulling slowly and rotating

out of the freezer barrel. As the auger is

withdrawn, remove each plastic flight and spring

from the auger. Be careful not to scratch inside of

freezer barrel when removing flights or auger.

Remove the spring from each auger flight.

4. Keep the rear of the auger tipped up once it is

clear of the freezer barrel.

5. Wipe spline lubricant off hex end of auger with a

paper towel. Remove the rear seal. Figure 15.

Figure 14. Auger Flight Removal

3.5 CLEANING DISASSEMBLED PARTS

Disassembled freezer parts require complete cleaning,

sanitizing and air drying before assembling. Local and

state health codes will dictate the procedure required.

Some state health codes require a four sink process (pre-

wash, wash, rinse, sanitize, air dry), while others require

a three sink process (without the pre-wash step). The

following procedures are a general guideline only. Consult

your local and state health codes for procedures required

in your location.

A. To clean the freezer parts, disassemble all parts.

(Refer to section 3.4 for the disassembly of freezer

parts.)

B. Place all front door and auger parts in clean 90° to

110°F (32°C to 43°C) water and wash thoroughly

(four sink procedure only).

C. Place all parts in 90° to 110°F (32°C to 43°C) , mild

detergent water and wash thoroughly.

D. Rinse all parts with clean 90° to 110°F (32°C to

43°C) water.

F. Sanitize all freezer parts following procedures out

lined below.

3.6 SANITIZE FREEZER PARTS

A. Use a sanitizer mixed according to manufacturer's

instructions to provide a 100 parts per million strength

solution. Mix sanitizer in quantities of no less than 2

gallons of 90° to 110°F (32°C to 43°C) water. Allow

the sanitizer to contact the surfaces to be sanitized

for 5 minutes. Any sanitizer must be used only in

accordance with the manufacturer's instructions.

B. Place all parts in the sanitizing solution for 5 minutes,

then remove and let air dry completely before assem

bling in freezer.