19

NOTE

If the mix lines or air line is difficult to remove, soften

with a rag soaked in hot water. Hose connections

may be sprayed with Haynes Sanitary Lubricant for

ease of removal. Do not loosen or remove the mix

pump cover wingnuts. Maintain the mix pump hose

in its operational condition.

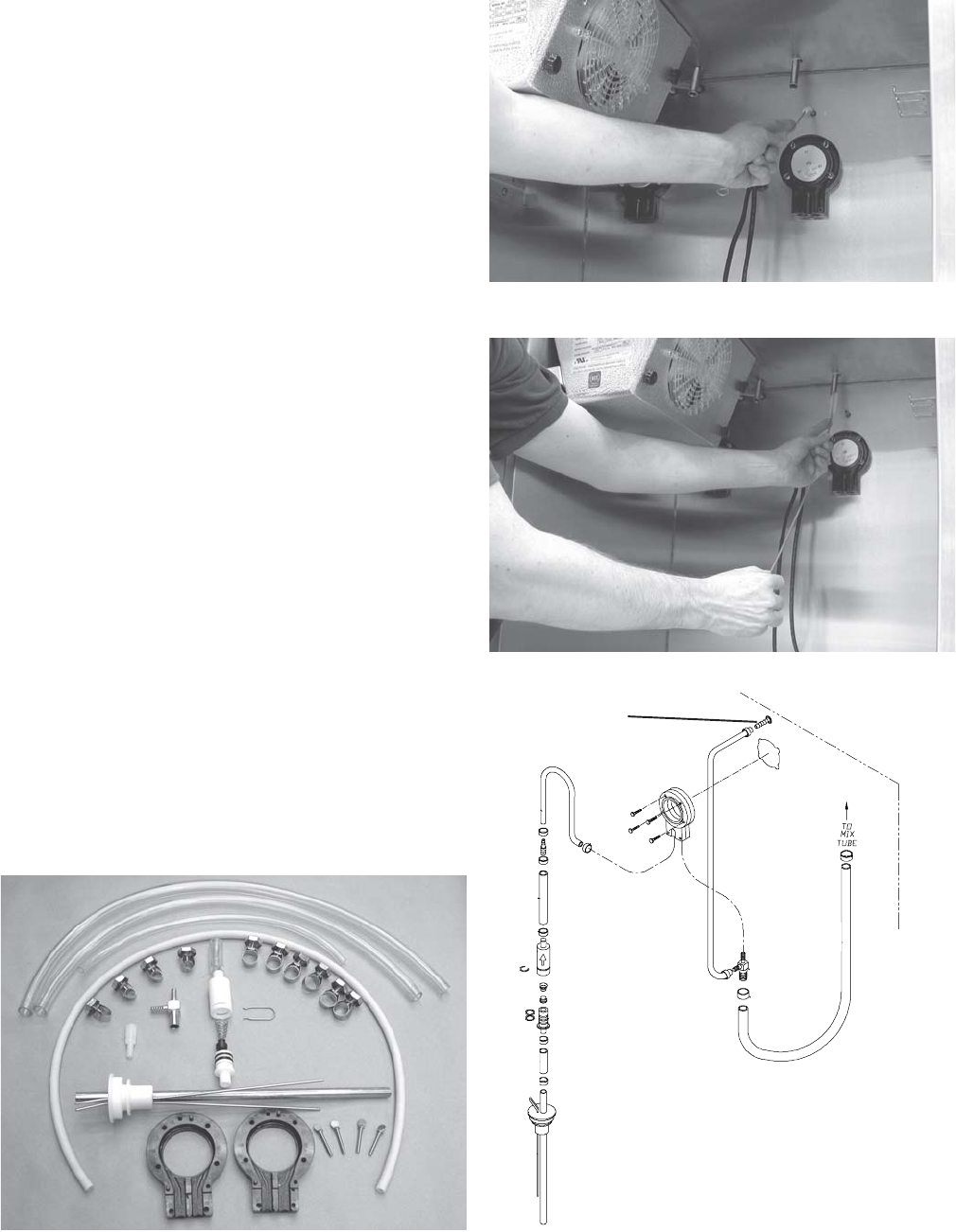

1. Loosen clamp and remove air hose from pump

compressor.

2. Loosen clamp and disconnect mix pump hose.

Remove the pickup hose, mix check valve and pickup

hose adapter (and bag adapter if applicable) as an

assembly from mix container.

3. Completely disassemble both hose assemblies and

check valve. Place hoses, tee, check valve assem-

bly, and pickup hose adapter in 90° to 110°F (32°C to

43°C), mild detergent water and wash thoroughly. Use

soft bristle brushes to clean inside of fittings. Rinse

all parts in clean 90° to 110°F (32°C to 43°C) water

(see Figure 24).

4. Carefully inspect each part for wear or damage.

Replace worn or damaged parts.

5. Wash feed tube and air tube with 90° to 110°F deter-

gent water and brushes provided. Rinse with clean,

90° to 110°F water (See Figure 25 and 26).

6. Prepare two gallons (7.5 liters) of sanitizing solution

using a USDA certified grade sanitizing solution.

Sanitize all removed parts, then air dry.

7. Check Hose Service Record decal to determine if

hose

reposition or replacement is required at this

time.

8. Reassemble both hose assemblies per the diagram

located on the inside of the cab door. Reconnect

assemblies to the pump and discharge hose, using

the clamps. (See Figure 27 or refer to Section 2.5 Mix

Pump).

Figure 26. Cleaning Feed Tube

Figure 25. Cleaning Air Tube

Figure 24. Removable Parts Figure 27. Mix Pump Tube Routing

Pump

Compressor

9. Sanitize assembled freezer as per instructions

outlined in Section 3.9).