RLC-SVD03A-EN 83

Variable Speed Fan System

.6 VDC. If there is no voltage at either of these two test points, check the

incoming 115 VAC between pins J6-1 (hot) and J6-5 (neutral) and check

fuse F1, mounted on the upper right-hand corner of the circuit board. If

the fuse is OK and the voltage between J6-1 and J6-5 is 115 VDC, but the

TP1 and TP2 voltages are out of range, replace the compressor module.

7. Remove connector P9 or P10 (whichever applies) from the inverter and

place a jumper wire between terminals F and FR on the female connec-

tor. See Figure 11-1 for the location of these wires. This will prevent the

control from reporting a fault diagnostic. Restart the unit and carefully

measure the DC voltage between wires C (+) and CR ( - ) on the same

female connector. The voltage should be 2 to 10 VDC when the compres-

sor on the affected circuit is running. At compressor start, this voltage

will start at approximately 2 VDC and gradually ramp up to about 10 VDC.

This voltage level is directly proportional to fan speed. At 5 VDC, the fan

should be running at 50% of full speed and at 7 VDC the fan should be

running at 70% of full speed.

NOTE: The output from the compressor module is a pulse width modulated

signal, 10 volt peak and 10 Hz. fundamental. It's average value can be read

with a DC voltmeter.

8. Remove the jumper wire and reconnect connector P9 or P10. While the

inverter is still powered, measure the DC voltage between pins J9-4 (+)

and J9-3 ( - ) on the compressor module. The connector must be plugged

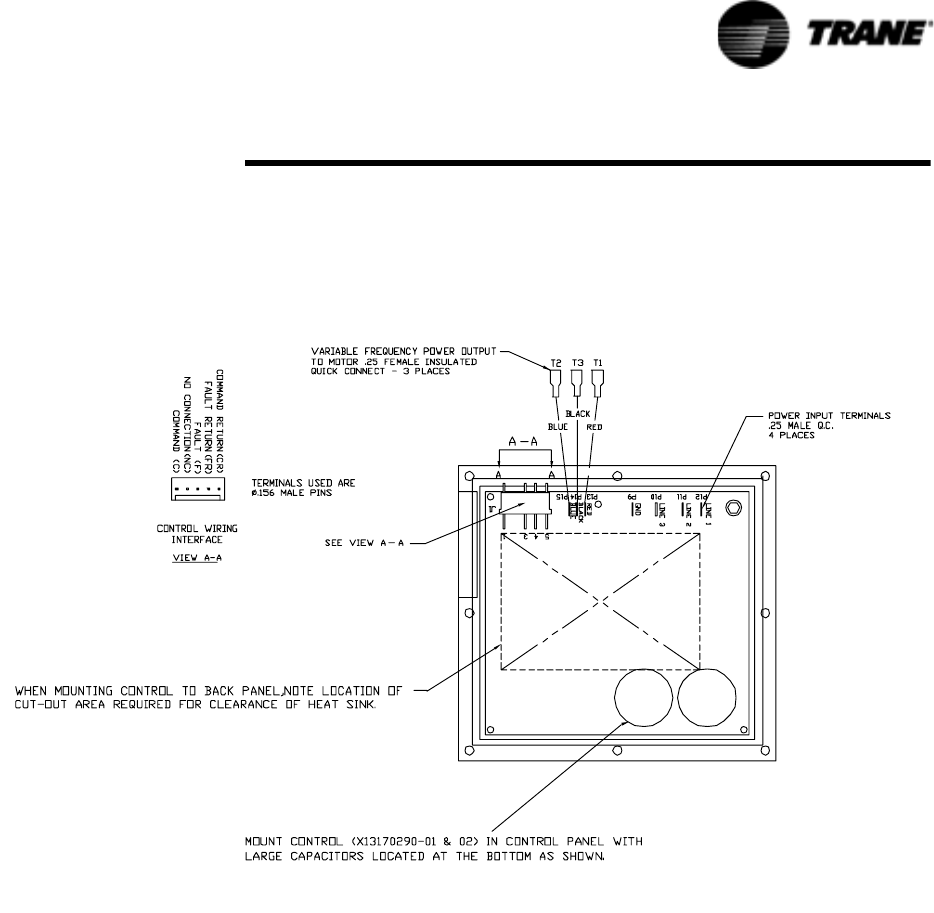

Figure 25 Variable Speed Fan Inverter