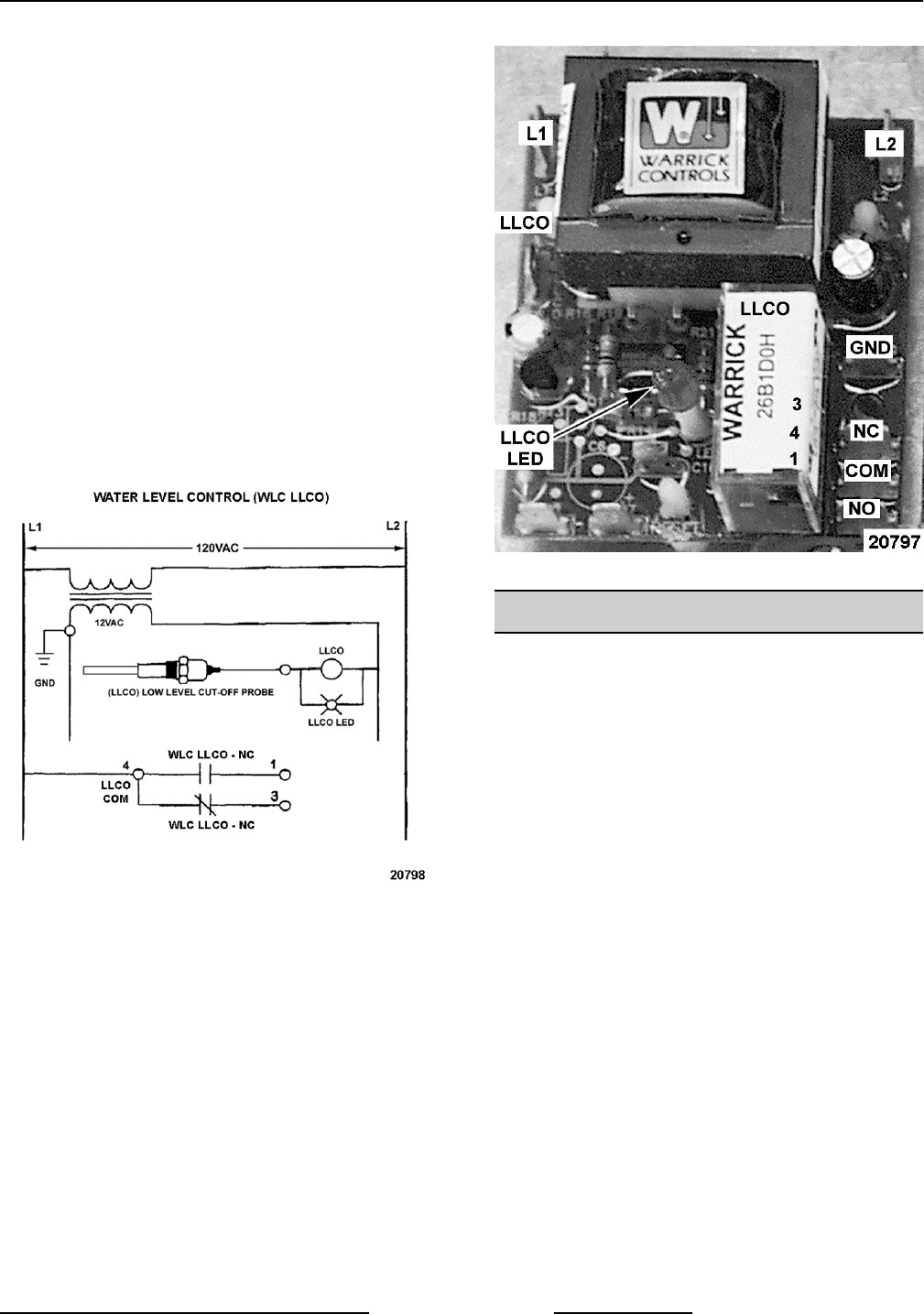

transformer secondary is powered through a series

path to chassis ground. The other side of the

transformer secondary (12VAC) is connected to the

LLCO coil and the LLCO LED. The grounded potential

is carried through the water in the reservoir jacket to

the LLCO probe. When the kettle is in the full upright

position and the reservoir jacket fluid is at the proper

level, the fluid is in constant contact with the LLCO

probe and the circuit is completed.

When the power switch is turned ON, power is

supplied to the water level control. With the kettle in

the full upright position and the fluid level in the

reservoir jacket in contact with the LLCO probe, the

LLCO relay coil is energized. The LLCO relay contacts

WLC LLCO-NC open, WLC LLCO-NO close and the

LLCO LED turns on. When the kettle is tilted to empty

the contents, the fluid is no longer in contact with the

LLCO probe and the circuit is open. The LLCO relay

coil is de-energized and LLCO LED turns off.

Fig. 36

Fig. 37

SEQUENCE OF OPERATION

1. Conditions.

A. Kettle connected to correct voltage supply

and is properly grounded.

1) 120VAC potential across X2 and X1 on

secondary of main transformer.

B. Power switch and light (1LT) (amber) are

off.

C. Low water light (2LT) (red) is off.

D. Pressure switch (1PAS) contacts closed.

E. Temperature dial at lowest setting

(potentiometer fully CCW).

1) Internal relay contacts N.O. are open.

F. Kettle at room temperature and in the full

upright position.

2. Power switch turned ON.

A. Power light (1LT) (amber) comes on.

B. Power from secondary of main transformer

to control circuit thru pressure switch

(1PAS) N.C. contacts.

3. Water level control (WLC) energized.

A. WLC LLCO probe satisfied (fluid in kettle

reservoir jacket at proper level).

Electric Stationary and Tilting Kettles - ELECTRICAL OPERATION

Page 23 of 29 F45472 (1112)