25

Fig. 1

Fig. 2

TECHNICAL DATA

Table no.1

TABLE N°1: Conversion to various types of gas APPLIANCE CATEGORY: II2H3+

Burner Types of Gas Pressure Nozzle

Diameter

Rater Capacity Reduced

Capacity

by-pass Diameter

Mbar 1/100 mm. g/h l/h kw kcal/h kw Kcal/h 1/100 mm.

Natural G20 20 72 - 95 1 860 0,48 413 34

Auxiliary Butane G30 28 50 73 - 1 860 0,48 413 34

Propane G31 37 50 71 - 1 860 0,48 413 34

Semi- Natural G20 20 97 - 167 1,75 1505 0,6 516 36

rapid Butane G30 28 65 127 - 1,75 1505 0,6 516 36

Propane G31 37 66 125 - 1,75 1505 0,6 516 36

Natural G20 20 115 - 286 3 2580 1,05 903 52

Rapid Butane G30 28 85 218 - 3 2580 1,05 903 52

Propane G31 37 85 214 - 3 2580 1,05 903 52

Double Natural G20 20 135 - 334 3,5 3010 1,8 1548 65

Ring Butane G30 28 95 254 - 3,5 3010 1,8 1548 65

Propane G31 37 95 250 - 3,5 3010 1,8 1548 65

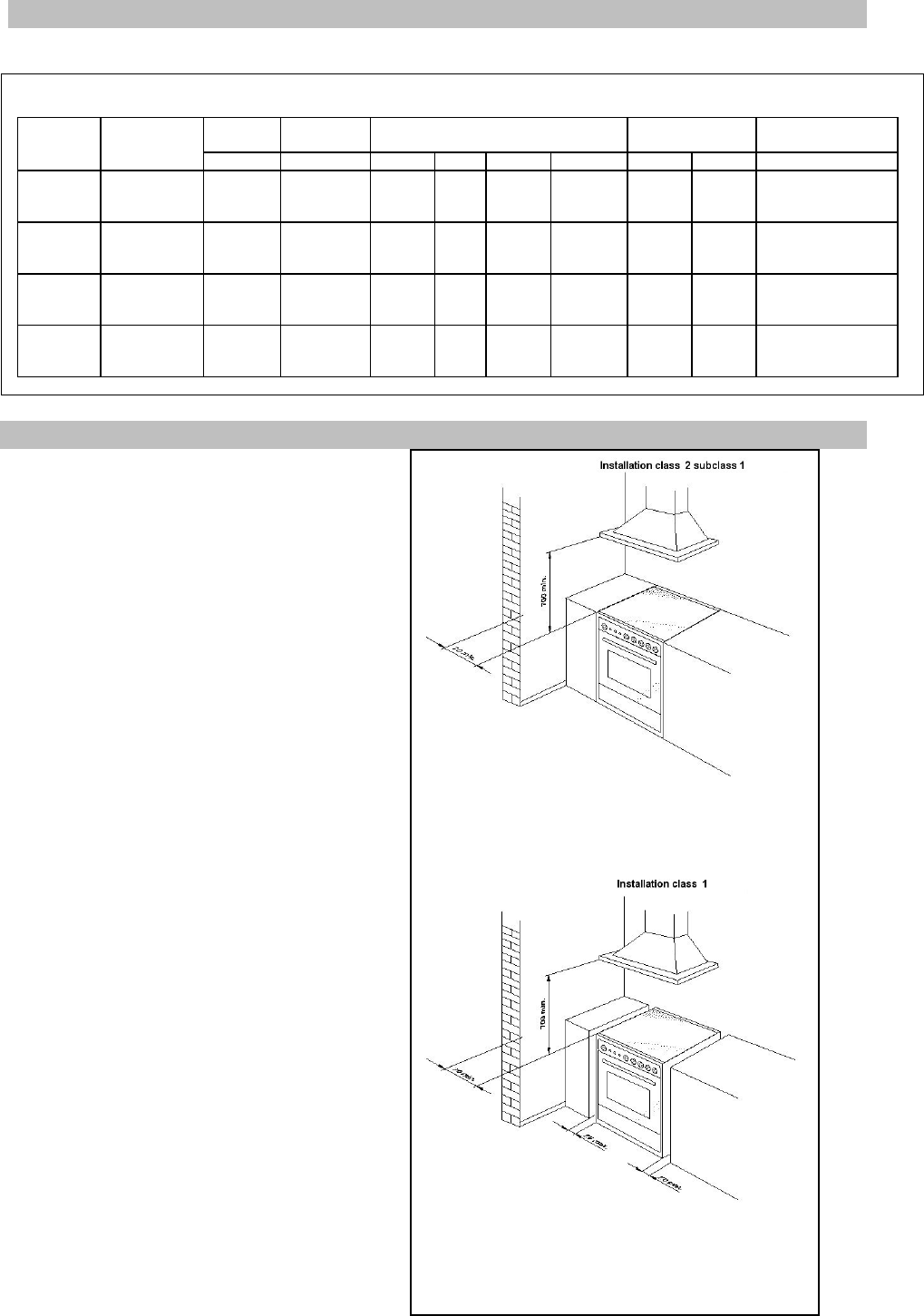

INSTALLATION

Positioning

Remove all the packaging and install the cooker

in a dry, ventilated room not near curtains,

paper, alcohol, petrol etc.

The appliance must be set on a heatproof, level

floor.

This appliance is approved to class “Y”

(EN60335-2-6 plus subsequent amendments).

This means that the appliance can be installed

up against a wall with a distance of not less than

20mm (fig 2) or inserted between 2 walls (fig 1).

Only one side wall can exceed the height of the

work surface and it must have a distance of

70mm from the edge of the cooker.

Any walls of the adjacent kitchen furniture and

the wall behind the cooker must be made with

heat resistant material that can withstand a

minimum temperature rise of 65K.

Any overhanging cabinetry installed above the

work surface must be located at a distance of no

less than 700mm.