DISCHARGE LINE CHECK VALVE — On all 30HL, HWA

units, a factory-supplied check valve is shipped with the unit

(two valves are provided for 30HLunits). The check valve(s)

should be installed in the discharge line(s) downstream from,

but close to, the compressor muffler. Install the valve in any

position except bonnet down.

The check valve(s) prevents backwards-migration of re-

frigerant from the condenser(s) to the compressor(s) and cooler

during the compressor off cycle.

HOT GAS BYPASS VALVE — On units equipped with the

factory-installed capacity reduction option (30HW only), a

hot gas bypass valve is located between the discharge line

and the cooler entering-refrigerant line. A solenoid valve is

installed in the equalizer line of the hot gas valve to allow

the temperature control to cycle the hot gas bypass function.

The amount of capacity reduction achieved by the hot gas

bypass valve may be altered by adjusting the spring tension

of the hot gas bypass valve. The total unit capacity should

not be reduced below 10% of the nominal rating.

LIQUID LINE SOLENOID VALVE (30HL ONLY) — The

solenoid valve closes when its circuit is inoperative, either

from capacity control or from any safety trip.

PRESSURE RELIEF DEVICES — All 30HK, 30HL, and

30HW units are equipped with a compressor pressure relief

valve located on the crankcase of the 06E compressor units

(except for the 30HW018 units which have a compressor

displacement less than 50 cfm). The pressure relief valve opens

at 450 psig (3103 kPa).

The 30HK,HWC, and HWS units are also equipped with

a high-side refrigerant pressure relief valve on the shell and

tube condenser. The valve is set to open at the working pres-

sure of the condenser, as shown in Table 7.

The 30HWB does not have a condenser pressure relief

valve, because the brazed-plate condenser is not considered

a pressure vessel, as defined in ANSI/ASHRAE 15 (Ameri-

can National Standards Institute/American Society of Heat-

ing, Refrigerating, and Air Conditioning Engineers) safety

code requirements.

For 30HL and HWA condenserless units, pressure relief

devices designed to relieve at 450 psig (3103 kPa), must be

field-supplied and installed in the discharge line piping after

the muffler in accordance withANSI/ASHRAE 15 safety code

requirements. Additional pressure relief valves, properly se-

lected, must be field-supplied and installed to protect high

side equipment and may be required by applicable codes.

Most codes require that a relief valve be vented directly

to the outdoors. The vent line must not be smaller than the

relief valve outlet. The condenser relief valves have a

5

⁄

8

-in.

SAE (Society of Automotive Engineers, U.S.A.) flare connec-

tion. The compressor relief valves have a

3

⁄

8

-in. SAE Flare

connection. Consult ANSI/ASHRAE 15 for detailed infor-

mation concerning layout and sizing of relief vent lines.

All units have a factory-installed fusible plug in the suc-

tion line which relieves on a temperature rise at 170 F

(77 C) and one in the liquid line which relieves at 210 F (99 C).

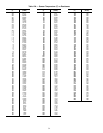

Table 7 — Pressure Relief Valve Settings

UNIT

PRESSURE RELIEF VALVE SETTINGS

Psig kPa

30HK 385 2655

30HWC 365 2517

30HWS 335 2310

Compressor and Unit Protective Devices

CIRCUIT BREAKER — There is a single circuit breaker

per compressor in each unit. The circuit breaker(s) protects

the compressor(s) against overloading, locked rotor condi-

tions, and primary single phasing. If the circuit breaker(s)

trips, determine the cause and correct it before resetting the

breaker(s).

COMPRESSOR INTERNALTHERMAL PROTECTION —

On the 30HW018 units, there is a sensor imbedded in

the compressor windings to detect an overtemperature

condition.

The thermostat opens and shuts off the compressor if the

discharge gas temperature exceeds 295 ± 5° F (146 ± 2.8° C).

The thermostat will reset when the temperature drops to ap-

proximately 250 F (121 C). However, the control module

will keep the unit locked off until control power is manually

cycled off, then back on.

NOTE: Compressor overtemperature protection for 30HK,

HL units is accomplished by high and low pressure switches

and circuit breakers which are external to the compressors.

CRANKCASE HEATER

Never open or disconnect any switch that energizes the

crankcase heater, unless the unit is being serviced or will

be shut down for an extended period. After service or

shutdown, energize the crankcase heater for 24 hours

before starting the compressor.

IMPORTANT: The crankcase heater is located in the

bottom corner of the compressor and held in place by

a bracket. The heater must be tight to prevent it from

backing out of the heater well. The heater eventually

burns out if exposed to the air for an extended period.

The heater in each compressor prevents absorption of liq-

uid refrigerant by the compressor oil when the compressor

is not operating. The heater is wired into the normally closed

contacts of the compressor control relay so that it energizes

only when the compressor is not operating. The heater is

125 w, 115 v on all 60 Hz units; 230 v on 50 Hz 30HK, HL

units; and 115 v on 50 Hz 30HW units.

OIL PRESSURE SAFETY SWITCH (OPS) — One OPS per

compressor is standard on all 30HL and HWA units, and on

all units equipped with the medium temperature brine op-

tion. One is located in each compressor terminal box with

capillaries to the crankcase and oil pump. The switch is also

offered as an accessory (part number 30HW900006) for stand-

ard 30HK, HWB, HWC, and HWS units. When used, the

OPS is monitored by the unit control module. If at any time

after the compressor is started, the OPS is open for more

than 2 minutes, the compressor shuts down and is locked off

until control power is manually cycled to OFF, then back to

the ON position. The OPS cuts out at5±1psig (34.5 ±

6.9 kPa), and has a maximum cut-in of 9.5 psig (65.5 kPa).

Check Unit Safeties

CONTROL MODULE — The unit control module is lo-

cated in the control section of the control box. See Fig. 19

and 20. It performs several functions. The control module

has a built-in compressor anti-short-cycle timer which will

not allow a compressor to restart until 5 minutes have elapsed

since the previous shutdown.

On 30HL and HWA units (and 30HK, HWB, HWC, and

HWS units equipped with the oil pressure safety switch [OPS]

accessory), the compressor oil pressure and low-pressure

switch(es) (LPS) are monitored through the control module.

The unit is allowed to remain operational as long as the OPS

and/or LPS have not been open for more than 2 minutes af-

ter a compressor has started. After start-up, if the OPS and/or

LPS are open for more than 2 minutes, the control module

shuts down the compressor and places the unit in a lockout

condition. The control module activates the fault indication

circuit, and the unit service lamp is illuminated. The unit

cannot be restarted until control power is manually cycled to

OFF, then to ON.

28