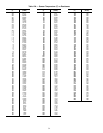

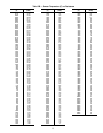

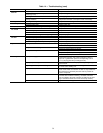

Table 11 — Capacity Control Steps —

30HW Standard Units

UNIT CAPACITY CONTROL CAPACITY OPERATING

30HW STEPS* % CYLINDERS

018

1 33.3 2

2 66.7 4

3 100.0 6

025

1 50.0 2

2 100.0 4

028

1 33.3 2

2 66.7 4

3 100.0 6

035

1 33.3 2

2 66.7 4

3 100.0 6

040

1 33.3 2

2 66.7 4

3 100.0 6

*Factory-installed hot gas bypass option adds an additional capacity

step to that shown in this table.

SERVICE

ELECTRIC SHOCK HAZARD

To avoid the possibility of electrical shock,

turn off all power to unit before servicing.

Do not attempt to bypass, short-out, or modify the con-

trol circuit or electronic boards in any way to correct a

problem. This could result in component failures or a

hazardous operating condition.

Compressor Replacement — If a replacement

6-cylinder compressor has a center-bank cylinder head with

discharge valve pad facing the pump end, remove head and

install reverse flange head from original compressor (dis-

charge valve pad toward the motor end). Center-bank cyl-

inder head cannot be rotated 180 degrees.

Be sure all the hardware from the old compressor is

removed and installed on the new compressor, including

the high-pressure switch snubber, the discharge gas thermo-

stat (30HW025-040), the oil pressuresafety switch (if equipped),

and the low-pressure switch.

The compressor can be removed from either the front or

the sides of the unit, depending on where clearance space

was allowed during unit installation.The compressor and mount-

ing hardware are mounted on a plate which is screwed down

to the unit basepan. Remove the 4 screws holding the plate

to the basepan and the plate should easily slide out of the

unit. Mount the replacement compressor to the plate, slide

the plate back into the unit and secure with the 4 screws.

Circuit Breaker(s) — The breaker(s) provides 3-leg over-

load protection. Do not bypass connections or increase the

size of the circuit breaker(s) to correct trouble. Determine

the cause of the trouble and correct it before resetting the

breaker(s).A tripped breaker must be manually reset by mov-

ing the circuit breaker handle to OFF, then ON position. See

Tables 4A and 4B for must-trip amps (MTA).

NOTE: One circuit breaker is provided per compressor.

Brazed-Plate Cooler and Condenser Heat Ex-

changer Replacement —

Brazed-plate heat exchang-

ers cannot be repaired if they develop a leak. If a leak (re-

frigerant or water) develops, the heat exchanger must be

replaced. To replace a brazed plate heat exchanger:

1. Disconnect the liquid-in and liquid-out connections at the

heat exchanger.

2. Check that the replacement heat exchanger is the same as

the original heat exchanger. For the condensers, compare

part numbers on the heat exchangers. For the coolers, in-

sulation covers the manufacturer’s part number. Make sure

the depths of the replacement and original cooler heat ex-

changers are the same.

3. Reclaim the refrigerant from the system, and unsolder the

refrigerant-in and refrigerant-out connections.

4. Remove the four

1

⁄

2

-in. nuts holding the heat exchanger

to the brackets. Save the nuts.

5. Install the replacement heat exchanger in the unit and

attach to the bracket using the four

1

⁄

2

-in. nuts removed

in Step 4.

6. Carefully braze the refrigerant lines to the connections on

the heat exchanger. Lines should be soldered using silver

as the soldering material with a minimum of 45% silver.

Keep the temperature below 1472 F (800 C) under nor-

mal soldering conditions (no vacuum) to prevent the cop-

per solder of the brazed plate heat exchanger from changing

its structure. Failure to do so can result in internal or

external leakage at the connections which cannot be

repaired.

7. Reconnect the water/brine lines.

8. Dehydrate and recharge the unit. Check for leaks.

Brazed-Plate Cooler and Condenser Heat Ex-

changer Cleaning —

Brazed-plate heat exchangers must

be cleaned chemically.Aprofessional cleaning service skilled

in chemical cleaning should be used. Use a weak acid (5%

phosphoric acid, or if the heat exchanger is cleaned fre-

quently, 5% oxalic acid). Pump the cleaning solution through

the exchanger, preferably in a backflush mode. After clean-

ing, rinse with large amounts of fresh water to dispose of all

the acid. Cleaning materials must be disposed of properly.

The mesh screens in front of the water/brine inlets of the

heat exchangers should be cleaned periodically, depending

on condition of the chiller water/brine.

Shell-and-Tube Condenser Cleaning — The shell-

and-tube condenser tubes can be cleaned either mechani-

cally or chemically. To clean them chemically, follow the

procedure described in Brazed-Plate Cooler and Condenser

Heat Exchanger Cleaning section above.

To clean the condenser tubes manually:

1. Order tubing brushes (Carrier part no. KC21AH105).

2. Close the valves on the condenser and relieve condenser

water pressure. BE SURE TO PROVIDE DRAINAGE

TO PREVENT WATER DAMAGE.

3. Remove the condenser heads and brush the tubes clean,

removing scale and other deposits.

4. Inspect the head gaskets and replace if necessary.

5. Clean all gasket surfaces prior to reassembly.

6. Replace the water heads and torque the head bolts to

90 ft-lb (122 N-m). Allow the gaskets to set overnight

and re-torque the bolts to ensure proper sealing.

32