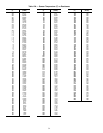

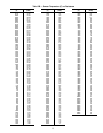

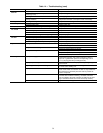

Table 14 — Troubleshooting (cont)

SYMPTOMS CAUSE REMEDY

Compressor

loses oil

Leak in system Repair leak.

Mechanical damage (blown piston or broken

discharge valve)

Repair damage or replace compressor as needed.

Oil trapped in line Check piping for oil traps.

Crankcase heater not energized

during shutdown

Check wiring and crankcase heater contacts on the

temperature controller, and replace heater if necessary.

Hot liquid line Shortage of refrigerant due to leak Repair leak and recharge.

Frosted liquid line Shutoff valve partially closed or restricted Open valve or remove restriction.

Restricted filter drier Replace filter drier.

Frosted suction line Expansion valve admitting excess refrigerant Adjust expansion valve. Replace valve if defective.

Compressor will

not unload

Burned-out coil Replace coil.

Defective capacity control valve Replace valve.

Miswired solenoid Rewire correctly.

Weak, broken, or wrong valve body spring Replace spring.

Compressor will

not load

Miswired solenoid Rewire correctly.

Defective capacity control valve Replace valve.

Plugged strainer (high side) Clean or replace strainer.

Stuck or damaged unloader piston or piston ring(s) Clean or replace the necessary parts.

System noises Piping vibration Support piping as required.

Check for loose pipe connectors.

Expansion valve hissing Add refrigerant.

Check for plugged liquid line strainer.

Compressor noisy Check valve plates for valve noise.

Replace compressor (worn bearings).

Check for loose compressor holddown bolts.

Freeze-up Improper charging Make sure a full quantity of fluid is flowing through the

cooler while charging, and suction pressure in cooler is

equal to or greater than pressure corresponding to 32 F

(0° C) (58 psig [400 kPa] for Refrigerant 22).

Improperly set safety thermostat Check safety thermostat for proper setting at beginning of

each season.

Operating with safety thermostat bypassed If thermostat was bypassed for checking, be sure it is back

in circuit before starting unit.

Improper circulation of condenser water Use adequately sized cleanable strainer in the condenser

water circuit. Make sure strainer is clean. It may sometimes

be necessary to chemically treat the water to prevent for-

mation of deposits.

System not drained for winter shutdown Remove drain plugs at end of cooling season. Blow out any

residual water. Instead of draining, a suitable anti-freeze

may be added to the water.

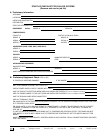

Damage to chiller due to freez-

ing is considered abuse and is not covered by warranty.

Loose Thermistor Tighten thermistor to pipe and reinsulate (30HW).

39