The control module also monitors the high-pressure

switch(es) and compressor internal thermal protection (30HW).

If at any time one or both of these switches opens, the con-

trol module shuts down the compressor and places the unit

in a lockout condition. The control module activates the fault

indication circuit, and the unit service lamp is illuminated.

The unit cannot be restarted until control power is manually

cycled to OFF, then to ON.

If the unit shuts down on an automatic reset switch, such

as the temperature controller, the compressor will be al-

lowed to restart when the switch closes and the control mod-

ule anti-short-cycle time has elapsed.

For Servicing Only — To speed up the 5-minute anti-short

cycle, a jumper may be placed between terminals T1 and T6

of the control module.

This jumper must be removed after servicing is complete.

Failure to remove this jumper is considered abusive treat-

ment and will void the Carrier warranty.

HIGH-PRESSURE SWITCH — A high-pressure switch is

provided to protect each compressor and refrigeration sys-

tem from unsafe high pressure conditions. See Table 8 for

high-pressure switch settings.

The high-pressure switch is mounted in the discharge side

of each compressor.A snubber is provided between the com-

pressor discharge manifold and the high-pressure switch to

prevent pressure pulsations from damaging the switch.

If an unsafe, high-pressure condition should exist, the switch

opens and shuts off the affected compressor. The unit control

module prevents the unit from restarting. The unit will not

restart until control power is manually cycled off, then on.

To check operation of the switch, slowly close the com-

pressor discharge shutoff valve until the compressor shuts

down. The switch should open at the pressure corresponding

to the appropriate switch setting as shown in Table 8.

Table 8 — Factory Settings, High-Pressure Switch

(Fixed)

UNIT

30

CUTOUT CUT-IN

Psig kPa Psig kPa

HK, HWS 280 ± 10 1931 ± 69 180 ± 20 1241 ± 138

HL, HWB, HWC 375 ± 10 2585 ± 69 275 ± 20 1896 ± 138

HWA 395 ± 10 2723 ± 69 298 ± 20 2054 ± 138

Reopen the compressor discharge shutoff valve, and cycle

the unit ON-OFF switch to OFF, then ON. The unit should

restart after the compressor anti-short-cycle delay, built into

the unit control module, expires.

LOW-PRESSURE SWITCH —Alow-pressure switch is pro-

vided to protect each compressor and system from a loss of

refrigerant. The low-pressure switch(es) also provides freeze

protection for the cooler. The low-pressure switch(es) is non-

adjustable. See Table 9 for low-pressure switch settings. One

switch is used for standard units, and a different switch is

used for units with the brine option.

Table 9 — Factory Settings, Low-Pressure Switch

(Fixed)

UNIT

TYPE

CUTOUT CUT-IN

Psig kPa Psig kPa

STANDARD 42±3 290±21 57±5 393±34

BRINE 27±3 186±21 44±5 303±34

To check operation of the low-pressure switch, slowly close

the suction service valve and allow the affected compressor

to pump down. The compressor should cut out when the suc-

tion pressure falls below the low-pressure switch cutout set-

ting. Open the suction service valve. The compressor should

restart after the low-pressure switch closes, and the com-

pressor anti-short-cycle delay expires.

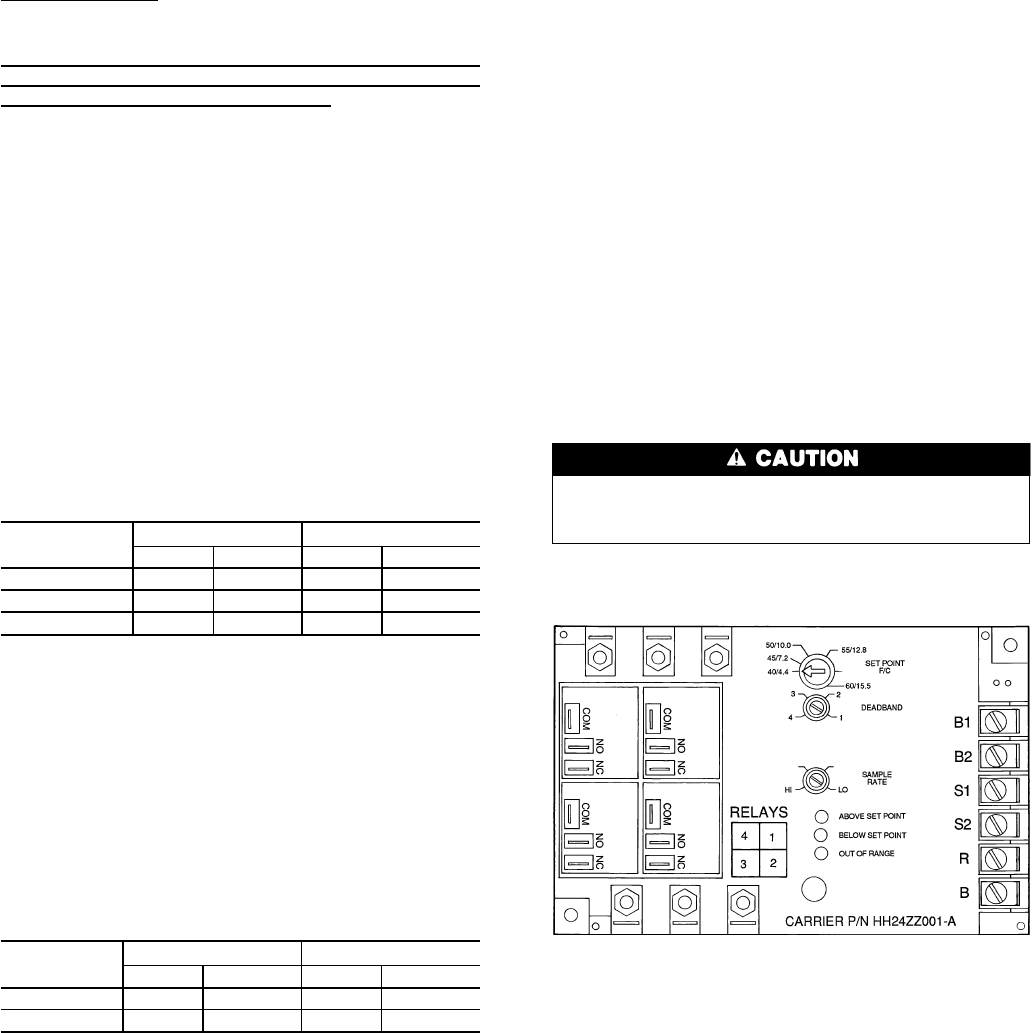

CHILLED FLUID TEMPERATURE CONTROLLER — All

units are equipped with a temperature controller (see

Fig. 21) which is capable of controlling up to 4 steps of ca-

pacity. A thermistor installed inside the cooler supplies the

input to the controller. The temperature controller can op-

erate a system with cooling ranges (entering cooler fluid tem-

perature minus leaving cooler fluid temperature) of 5° to

15° F (2.8° to 8.3° C), and with a range of set points from

40 to 60 F (4.4 to 15.5 C) for standard units, and 15 to

39 F (−9.4 to 3.9 C) for units with the medium temperature

brine option.

The set point of the temperature controller should be ad-

justed to the desired leaving cooler fluid temperature, and

verified by using a thermometer placed in the leaving-cooler

piping. The amount of deadband around the set point value

is adjusted through the use of the deadband adjustment knob

on the temperature controller. See Tables 5 and 6 for the cor-

rect setting of the deadband.

The unit should then control the average leaving-fluid tem-

perature to this setting. If the leaving-fluid temperature does

not correspond to the desired set point, slightly readjust the

controller set point knob until the desired leaving-fluid tem-

perature is obtained. The temperature controller has an ad-

justable 30-second (HI position) to 3-minute (LO position)

sample rate knob. The sample rate knob should always be

set at LO position (fully clockwise) for 30HK, HLunits, and

at HI position (fully counterclockwise) for 30HW units.

Do not force the knob dials past the stops. This

could cause loss of control point and damage to the

controller.

LEGEND

COM — Common

NC — Normally Closed

NO — Normally Open

Fig. 21 — Temperature Controller

29