TROUBLESHOOTING

Complete Unit Stoppage and Restart —

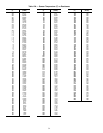

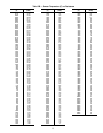

Pos-

sible causes for unit stoppage and reset methods are (also

see Table 14):

GENERAL POWER FAILURE — After power is restored,

restart is automatic through the normal timer cycle.

UNIT ON-OFF SWITCH IS OPEN — When the switch is

opened, the unit stops immediately. If the switch is closed

immediately after it was opened, the unit restarts automati-

cally after the 5-minute timer cycle is completed. If the switch

is closed after an extended off-period, the unit restarts au-

tomatically in approximately 3 seconds.

CONTACTS OF ANY AUXILIARY INTERLOCKS ARE

OPEN — After the problem has been corrected, restart is

automatic after completion of the 5-minute timer cycle.

CHILLED FLUID PROOF-OF-FLOWSWITCH(ES) OPEN

— After the problem causing the loss of flow has been cor-

rected, restart is automatic after completion of the 5-minute

timer cycle.

OPEN LOW-PRESSURE SWITCH — If a low-pressure switch

remains open for more than 2 minutes during unit operation,

the compressor(s) shuts down and is locked off. The unit ser-

vice light is illuminated. Determine and correct the cause of

the failure. The switch automatically resets, but the unit must

be manually reset by cycling the unit control power (move

the ON-OFF switch to OFF, then to ON). The unit restarts

after completion of the 5-minute timer cycle unless the re-

frigerant charge is either very low or lost. If this is the case,

determine the cause of the loss of charge, correct the prob-

lem, and recharge the unit before restarting.

TEMPERATURE CONTROLLER SHUTS UNIT DOWN

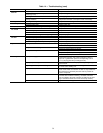

ON OUT-OF-RANGE (See Fig. 21) — Check the ther-

mistor for an open circuit failure. See Tables 12A and 12B

for temperature-resistance values. If thermistor is damaged,

replace it. If thermistor is not damaged, the unit restarts

automatically after completion of the 5-minute timer cycle,

and after the leaving cooler chilled fluid temperature

rises above the upper deadband limit of the temperature

controller.

OPEN HIGH-PRESSURE SWITCH(ES) — The unit ser-

vice light is illuminated. Determine and correct the cause of

the failure. The switch(es) automatically resets but the unit

must be manually reset by cycling the control power (move

ON-OFF switch to OFF, then back to ON). The unit restarts

after completion of 5-minute timer cycle.

OPEN COMPRESSOR INTERNALTHERMAL PROTEC-

TION (30HW UNITS) — This is compressor overtempera-

ture protector on 30HW018 units and the discharge gas ther-

mostat (DGT) on 30HW025-040 units. The unit service light

is illuminated. Determine and correct cause of problem. The

switch resets automatically but unit must be reset by cycling

the control power (move ON-OFF switch to OFF, then back

to ON). The unit restarts after completion of 5-minute timer

cycle.

OPEN OIL PRESSURE SWITCH — If oil pressure switch(es)

opens for more than 2 minutes during unit operation, the unit

shuts down and is locked off. The unit service light is illu-

minated. Determine and correct cause of failure. Unit must

be reset by cycling the control power (move ON-OFF switch

to OFF, then back to ON). Unit restarts after completion of

5-minute timer cycle.

OPEN CONTACTS ON COMPRESSOR GROUND-

CURRENT SENSOR(S) (Accessory) — The light-emitting

diode (LED) on the ground current accessory board (located

in field control wiring section of control box) is illuminated.

See Fig. 17-20. Unit service light is also illuminated. Check

the compressor motor windings for a short to ground.

Determine and correct cause of the failure. The unit must be

reset by cycling the control power (move ON-OFF switch to

OFF, then back to ON). Unit restarts after completion of the

5-minute timer cycle.

OPEN 24-V CONTROL CIRCUIT BREAKER(S) — De-

termine the cause of the failure and correct. Reset circuit

breaker(s). Restart is automatic after completion of 5-minute

timer cycle.

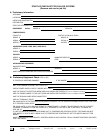

Fig. 24 — Elliott Tube Plug

HEAD BOLT TIGHTENING SEQUENCE

Fig. 25 — Typical Tube Sheet

37