7

Step 3 — Place the Unit

NOTE: These units are not suitable for unprotected outdoor

use.

Carrier recommends that these units be located in the base-

ment or on the ground floor. However, if it is necessary to lo-

cate the unit on an upper floor, be sure the structure has been

designed to support the unit weight. If necessary, add structural

support to floor. Also, be sure the surface for installation is

level. Refer to Fig. 4 and 5 for space requirements and weight

distribution.

Only electrical power connections, water connections for

condenser, fluid connections for evaporator, and strainer instal-

lation are required for 30MPW installation. Installation of

30MPA units varies only in field piping required for the remote

condenser.

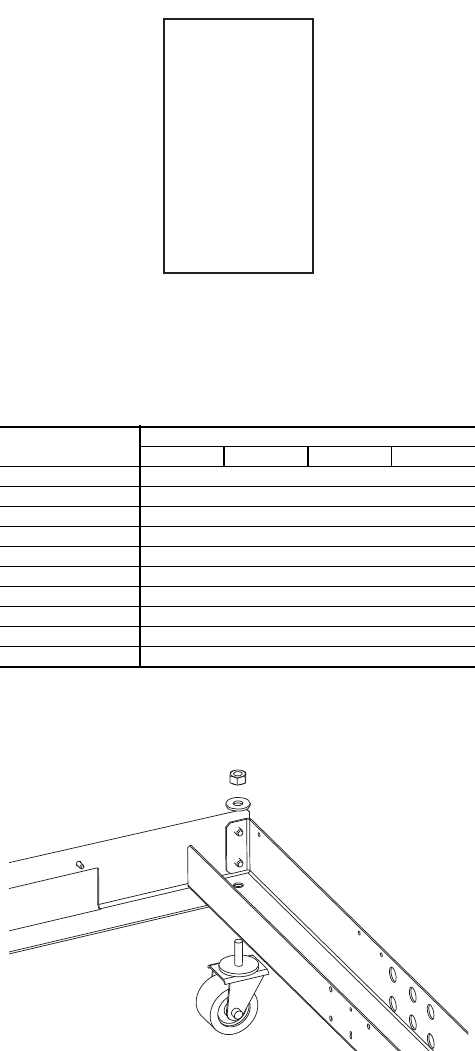

When the unit is in its final position, remove the packaging

and remove the mobility kit wheels (if equipped). Remove

3

/

8

-in. wheel nuts to remove wheels from unit legs. Level the

unit (using a level), and bolt the unit to the floor or pad.

If unit is to be mounted on unit external vibration

isolators, follow the mounting instructions included with

the accessory vibration isolator.

If unit has accessory leveling kit installed, follow the in-

structions provided with the accessory to make sure unit is lev-

el and in the correct position.

Step 4 — Check Compressor Mounting — As

shipped, units with two compressors are held down with 6 bolts

through rubber grommets. All units with three compresors are

held down with 8 bolts per pair through grommets. After unit is

installed, verify mounting bolt torque 7 to10 ft-lb (9 to 14 Nm).

Step 5 — Make Piping Connections — See

Fig. 8 and 9 for typical piping applications.

30MPA SYSTEM CONDENSER — For detailed condenser

piping installation instructions for 30MPA systems, refer to

separate instructions packaged with the remote condenser

units.

Condenser refrigerant piping for 30MPA units should be

sized to minimize the amount of refrigerant required.

The 30MPA units that use air-cooled evaporative condens-

ers must have adequate means for head pressure control when

operating below 60 F (15.6 C).

Carrier recommends that a field-supplied pressure relief de-

vice be installed in each discharge line of 30MPA units. Most

local codes require the discharge line relief valve to be vented

directly to the outdoors. The vent must not be smaller than the

discharge line relief valve outlet.

30MPW CONDENSER DESCRIPTION — All 30MPW

units use a brazed-plate heat-exchanger-type condenser. These

heat exchangers are made of embossed plates of acid-resistant

stainless steel. Every other plate is reversed so that the ridges

of the herringbone pattern intersect one another on adjacent

plates, forming a lattice of contact points. These plates are

vacuum-brazed together to form a compact and pressure-

resistant heat exchanger.

After brazing, the impressions in the plates form 2 separate

systems of channels where the refrigerant and water flows are

counterflow. The number of plates varies depending on unit

tonnage. The condensers provide approximately 10º to 12º F

(6º to 8º C) liquid subcooling at the standard Air Conditioning,

Heating and Refrigeration Institute (AHRI) rating condition.

30MPW CONDENSER — When facing the unit control box,

the condenser is the uninsulated heat exchanger located on the

left-hand side. The water connections are on the right-hand

side of the heat exchanger with the LIQUID-IN connection at

the bottom, and the LIQUID-OUT connection at the top.

A strainer with a minimum of 40 mesh must be installed

within 10 ft (3 m) of the condenser water inlet to prevent debris

from clogging or damaging the heat exchanger. The strainer is

required for operation and is available as an accessory.

To install the victaulic coupling (see Fig. 10):

1. Lubricate the gasket lips and stretch the gasket over

the end of the heat exchanger coupling. Avoid twisting

the gasket when installing.

2. Bring the pipe and heat exchanger coupling ends together

into alignment. Slide the gasket so that it is centered over

the ends. Apply a light film of lubricant to the gasket, or

to the outside diameter of the pipe. Avoid twisting the

gasket during installation.

B

A

C

D

CONTROL

PANEL

SIDE

WEIGHT DISTRIBUTION AT EACH MOUNTING

HOLE — Lb (kg)

UNIT 30MP

MOUNTING HOLE

ABCD

A015 156 (71)

A020 159 (72)

A030 181 (82)

A040 228 (104)

A045 234 (106)

W015 170 (77)

W020 176 (80)

W030 216 (98)

W040 275 (125)

W045 298 (135)

Fig. 6 — Mounting Hole Weight Distribution

a30-5040

Fig. 7 — Mobility Kit

a30-5041