15

Carrier’s packaged selection program provides quick,

easy selection of Carrier’s water-cooled chillers. The pro-

gram considers specific temperature, fluid and flow

requirements among other factors such as fouling and alti-

tude corrections.

Before selecting a chiller, consider the following points:

Leaving water (fluid) temperature (LWT)

• The LWT must be at least 40 F (4.4 C) or greater.

• If the LWT requirement is greater than 60 F (15.5 C), a

mixing loop is required.

Entering water (fluid) temperature (EWT)

• If the EWT requirement is greater than 70 F (21.1 C), a

mixing loop is required. The EWT should not exceed

70 F (21.1 C) for extended operation. Pulldown can be

accomplished from 95 F (35 C).

Evaporator flow rate or evaporator delta-T:

• The evaporator delta-T (EWT – LWT) must fall between

5 and 20° F (2.8 and 11.1° C) while still meeting the

maximum entering requirements.

• For larger or smaller delta-T applications, a mixing loop

is required. If the evaporator flow is variable, the rate of

change of flow should not exceed 10% per minute.

The loop volume in circulation must equal or exceed

3 gallons per nominal ton (3.2 L per kW) of cooling for

temperature stability and accuracy in normal air condi-

tioning applications. In process cooling applications,

there should be 6 to 10 gallons per ton (6.5 to 10.8 L

per kW). To achieve this loop volume, it is often neces-

sary to install a tank in the loop. The tank should be baf-

fled to ensure there is no stratification, and that water

(or brine) entering the tank is adequately mixed with liq-

uid in the tank. See Water Loop Volume in the Applica-

tion Data section.

Evaporator pressure drop:

• A high evaporator pressure drop can be expected when

the evaporator delta-T is low. A mixing loop can help to

alleviate this situation.

• The three-pass evaporator option is recommended to

increase performance when the evaporator delta T is

high. This is particularly helpful with brine applications.

Condenser pressure drop:

• A high condenser pressure drop can be expected when

the condenser delta-T is low. A one-pass condenser can

help lower pressure drop.

Series chillers:

• One-pass heat exchangers can help lower pressure

drop when heat exchangers are placed in series.

Water quality, fouling factor:

• Poor water quality can increase the required evaporator

fouling factor.

• Higher than standard fouling factors lead to lower

capacity and higher input kW from a given chiller size

compared to running the same application with better

water quality (and lower fouling factors).

Temperature reset:

• Return water (standard)

• Outside air temperature (standard)

• Space temperature (accessory sensor required)

• 4 to 20 mA (requires an energy management module)

Demand limit:

• 2-step (requires an energy management module)

• 4 to 20 mA (requires an energy management module)

• CCN Loadshed

Performance data

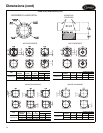

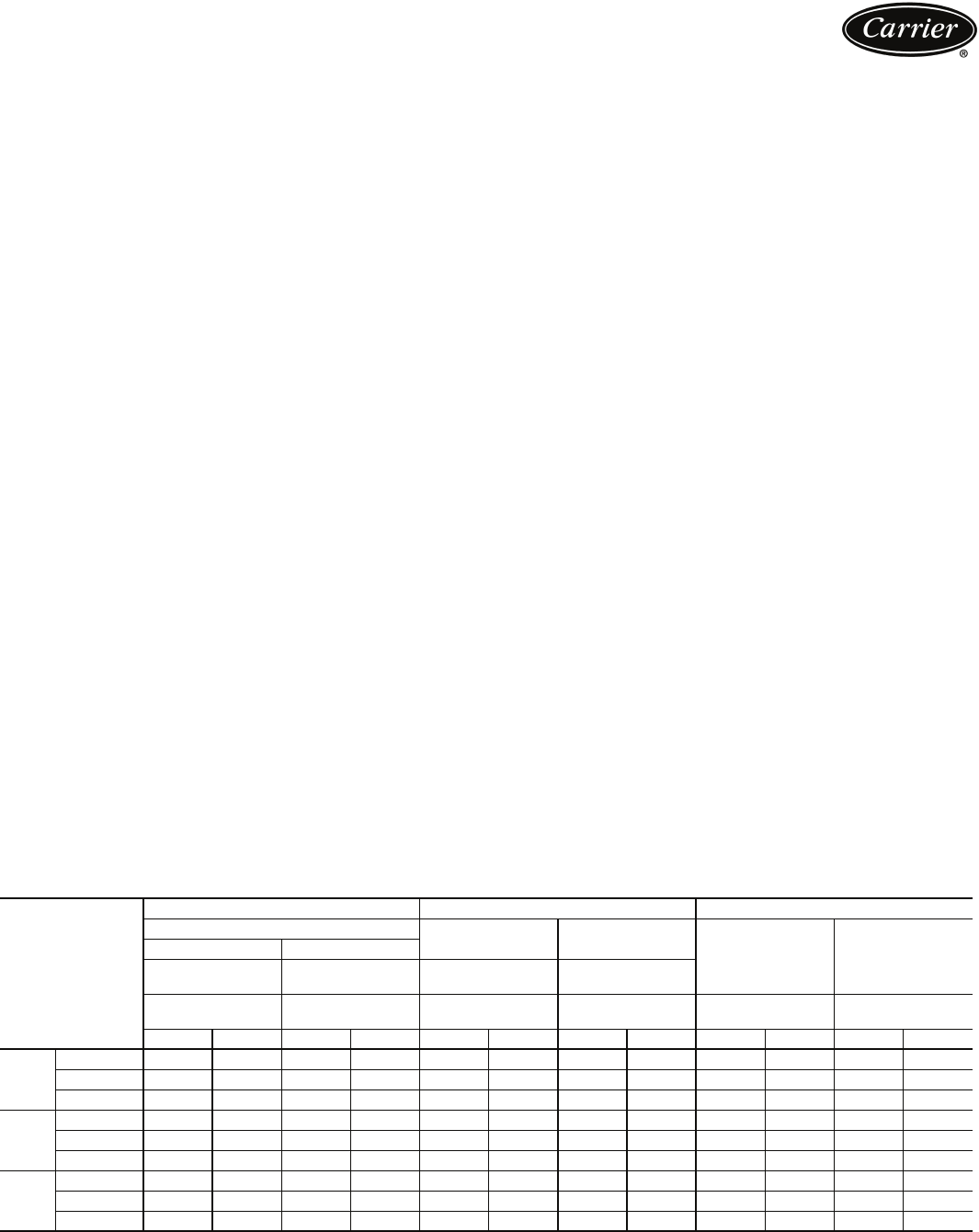

EVAPORATOR AND CONDENSER FLOW RATES

*Maximum condenser fluid temperature shown for standard condensing

option. Heat machine option may have leaving fluid temperatures up to

140 F (60 C).

30XW UNIT

EVAPORATOR CONDENSER NOMINAL

Leaving Fluid/Entering Fluid

Minimum Entering

Fluid

Maximum Leaving

Fluid

Evaporator Condenser

Minimum Maximum

40 F (4.4 C)/

45 F (7.2 C)

60 F (15.6 C)/

70 F (21.1 C)

65 F (18.3 C) 118 F (47.8 C)*

Minimum

Flow Rate

Maximum

Flow Rate

Minimum

Flow Rate

Maximum

Flow Rate

Nominal

Flow Rate

Nominal

Flow Rate

GPM L/s GPM L/s GPM L/s GPM L/s GPM L/s GPM L/s

325

Two pass 411 25.9 1481 93.4 494 31.1 1974 124.5 790 49.8 987 62.3

One pass 790 49.8 3126 197.2 987 62.3 3290 207.6 790 49.8 987 62.3

Three pass 247 15.6 987 62.3 — — — — 790 49.8 — —

350

Two pass 433 27.3 1557 98.2 519 32.7 2076 131.0 830 52.4 1038 65.5

One pass 830 52.4 3287 207.4 1038 65.5 3460 218.3 830 52.4 1038 65.5

Three pass 260 16.4 1038 65.5 — — — — 830 52.4 — —

400

Two pass 486 30.7 1751 110.4 584 36.8 2334 147.3 934 58.9 1167 73.6

One pass 934 58.9 3696 233.1 1167 73.6 3890 245.4 934 58.9 1167 73.6

Three pass 292 18.4 1167 73.6 — — — — 934 58.9 — —

Selection procedure