23

Variable evaporator flow rates

Variable flow rates may be applied to a standard chiller.

The unit will, however, attempt to maintain a constant

leaving fluid temperature. In such cases minimum flow

must be in excess of minimum flow given in the

Evaporator and Condenser Flow Rates table, and mini-

mum loop volume must be in excess of 3 gallons per ton

(3.21 L per kW). Combined flow rate and change in load

must not change by more than 10% per minute. Additional

loop volume may be necessary to ensure fluid is not quickly

recirculated back to the chiller before the chiller has

adjusted to the previous change in flow rate and load

condition.

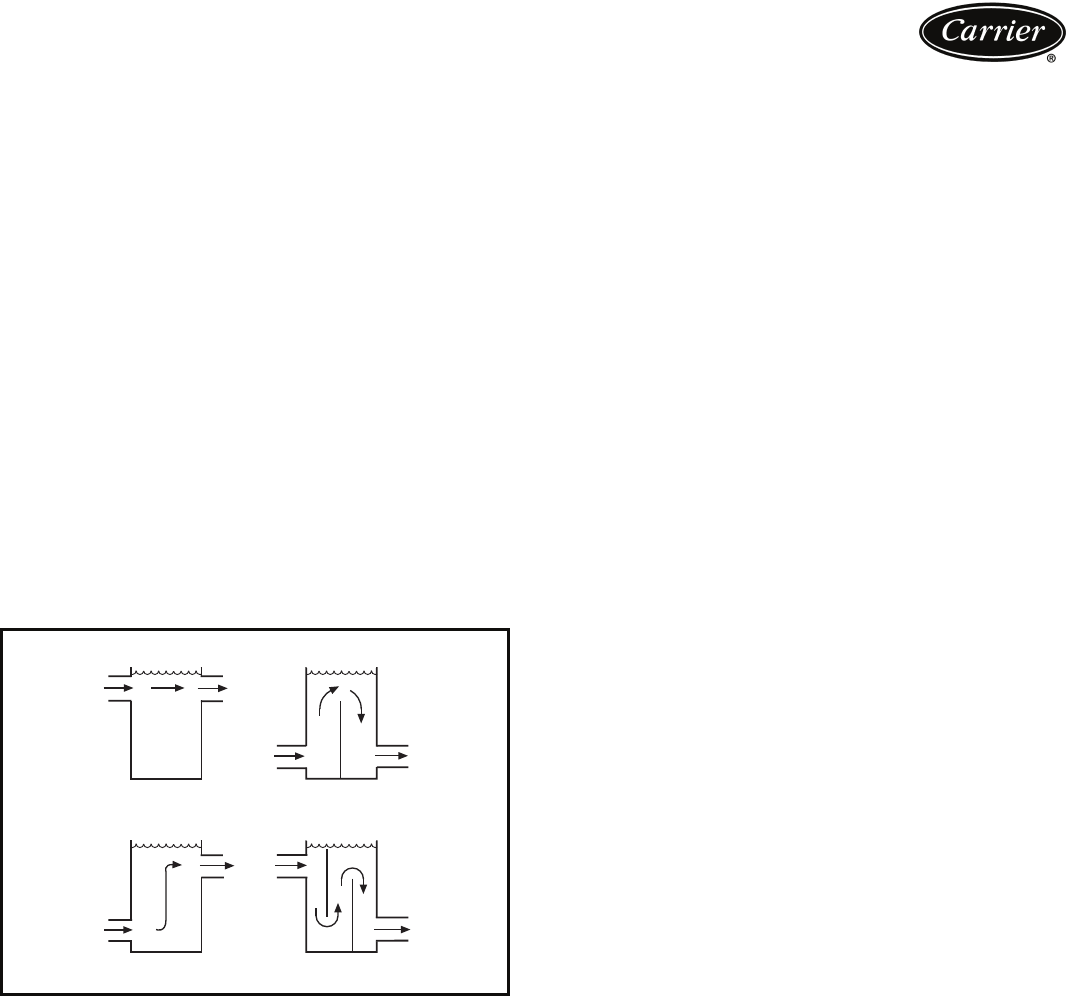

Water loop volume

The loop volume in circulation must equal or exceed 3 gal.

per nominal ton (3.2 L per kW) of cooling for temperature

stability and accuracy in normal air-conditioning applica-

tions. In process cooling applications, there should be 6 to

10 gallons per ton (6.5 to 10.8 L per kW). To achieve this

loop volume, it is often necessary to install a tank in the

loop. The tank should be baffled to ensure there is no strat-

ification, and that water (or brine) entering the tank is ade-

quately mixed with liquid in the tank. See Tank installation

drawing.

Evaporator fouling factor

The fouling factor used to calculate tabulated ratings is

0.0001 sq ft hr F/Btu (0.000018 sq m C/W). As

fouling factor is increased, both unit capacity and EER

(Energy Efficiency Ratio) decrease. The impact of the foul-

ing factor on performance varies significantly with chiller

size and application conditions. Ratings must be deter-

mined by the Carrier selection program.

Condenser minimum flow rate

The minimum condenser flow rate is shown in the Mini-

mum and Maximum Condenser Flow Rate Table. If the

condenser flow rate is below the minimum rate shown, try

increasing the number of condenser passes (1 or 2 pass

available).

Evaporator and condenser freeze protection

The solution concentration must be sufficient to protect the

chilled water loop to a freeze protection (first crystals)

concentration of at least 15 F (8.3 C) below the leaving

fluid temperature set point. If chiller fluid lines are in an

area where ambient conditions fall below 34 F (1.1 C), it is

recommended that an antifreeze solution be added to pro-

tect the unit and fluid piping to a temperature 15 F

(8.3 C) below the lowest anticipated temperature. For

corrections to performance, refer to the chiller selection

program.

NOTE: Use only antifreeze solutions approved for heat

exchanger duty. Use of automotive antifreeze is not recom-

mended because of the fouling that can occur once their

relatively short-lived inhibitors break down.

Multiple chillers

Where multiple chillers are required, or where standby

capability is desired, chillers may be installed in parallel.

Units may be of the same or different sizes. However,

evaporator flow rates must be balanced according to the

recommendations of each chiller to ensure proper flow.

Unit software is capable of controlling two units as a sin-

gle plant. Refer to the Controls, Start-Up, Operation, Ser-

vice and Troubleshooting guide for further details.

Dual chiller control

The chiller on board controller allows 2 chillers (piped in

parallel or series) to operate as a single chilled water plant

with standard control functions coordinated through the

master chiller controller. This feature requires a communi-

cation link between the 2 chillers. There are several advan-

tages to this type of control:

• Redundancy (multiple circuits)

• Better low load control (lower tonnage capability)

• Lower rigging lift weights (2 machines rather than one

large machine)

• Chiller lead-lag operation (evens the wear between the

two machines)

Parallel chiller operation

Parallel chiller operation is the recommended option for

dual chiller control. In this case, each chiller must control

its own dedicated pumps or isolation valves. Balancing

valves are recommended to ensure the proper flow to each

chiller. Two field-supplied and installed dual chiller leaving

water temperature sensors are required (one for each mod-

ule) for this function to operate properly.

Consider adding additional isolation valves to isolate

each chiller to allow for service on the machine, and still

allow for partial capacity from the other chiller.

Series chiller operation

Series chiller operation is an alternate control method sup-

ported by the chiller control system. Certain applications

might require that two chillers be connected in series. For

nominal 10 F (5.6 C) evaporator ranges, use the one-pass

heat exchanger options to reduce fluid side pressure drop.

Use the standard pass arrangement for low flow, high tem-

perature rise applications. Two field-supplied and installed

dual chiller leaving water temperature sensors are required

(one for each module) for this function to operate properly.

⋅

°

⋅

°

°

°

°

°

BAD

BAD

GOOD

GOOD

TANK INSTALLATION

a30-3185