2

Easy installation

The AquaForce

®

30XW screw chillers

are shipped with starter and unit

mounted flow switch installed and can

be shipped with a full R-134a refriger-

ant charge to minimize installation

time. The unit provides single point

power connection (using optional con-

trol power transformer) and quick, easy

piping connections (using Victaulic-

type clamp on couplings). The 30XW

200-v, 230-v, 460-v, and 575-v units

are designed in accordance with UL

(Underwriters Laboratory) and UL

Canada (Underwriters Laboratory,

Canada) standards to minimize electri-

cal inspection time.

Dual circuits

Dual independent refrigerant circuits

provide reliable, dependable cooling,

excellent part load operation, and

redundancy. Each circuit includes its

own compressor, electronic expansion

valve, filter drier, and sight glass to

assure operation.

High efficiency

The Aquaforce 30XW screw chiller

efficiency levels meet or exceed energy

efficiency requirements of ASHRAE

(American Society of Heating, Ventila-

tion and Air Conditioning Engineers)

90.1 2007 and CSA (Canadian Stan-

dards Association) for both full load and

part load operation and is certified to

AHRI standards.

Per AHRI 550/590, chillers operate at

design conditions less than one percent

of the time. As a result, superior part

load efficiency is required for today's

chilled water applications. The 30XW

chillers deliver integrated part-load

values (IPLV) as low as 0.468 kW per

ton at AHRI conditions while offering

the ability to operate in a broad range

of applications and climates. This

exceptional performance has a signifi-

cant impact on energy savings and cost

of ownership.

Heat recovery

The Aquaforce 30XW screw chiller

provides up to 140 F (60 C) leaving

condenser water (requires 300 psig

[2068 kPa] condenser option) when

applied in heat recovery applications.

Further, the 30XW unit heat control

mode can be utilized to maintain a con-

stant leaving condenser water tempera-

ture. Low source controls provide

evaporator suction protection to pre-

vent nuisance trips when operating in

heat recovery applications. This flexi-

ble capability allows a chiller to meet

both cooling and heating requirements

providing a high level of interchange-

ability within a chilled water plant.

Environmental leadership

Carrier has long been committed to the

environment and its sustainability. The

Aquaforce 30XW screw chiller pro-

vides customers with a high-efficiency,

chlorine free, long-term solution unaf-

fected by refrigerant phase outs.

Carrier's decision to utilize non-ozone

depleting R-134a refrigerant provides

customers with a safe and environmen-

tally sound choice without compromis-

ing efficiency. In addition, R-134a

refrigerant was given an A1 safety rat-

ing by ASHRAE, meaning that it is

among the safest refrigerants available.

Positive displacement screw

compression

Positive displacement compression

ensures stable operation under all load

conditions without the possibility of

compressor surge. High-efficiency

rotary twin screw compressors with

infinitely variable slide valves allow the

chillers to exactly match actual load

conditions, delivering excellent part

load performance.

Factory testing

A quick start-up is assured once instal-

lation is complete, since each 30XW

unit is manufactured at an ISO (Interna-

tional Organization for Standardiza-

tion) 9001:2000 listed manufacturing

facility to ensure quality. In addition, all

30XW units that are shipped with a full

charge of R-134a refrigerant are tested

under load at the factory to provide

reliable start-up.

Low starting current (inrush)

Dual circuit units stage the start up of

the compressors thereby reducing the

over all current draw by up to 40%.

Constant or variable evapora-

tor flow

Aquaforce 30XW screw chillers are

suitable for constant or variable evapo-

rator flow.

Hermetic motor

The Aquaforce 30XW chiller utilizes

motors that are hermetically sealed

from the machine room. Refrigerant is

used to cool the motor windings.

Carrier's hermetic design eliminates:

• Compressor shaft seals that require

maintenance and increase the likeli-

hood of refrigerant leaks.

• Machine room cooling requirements

associated with air-cooled motors,

which dissipate heat to the mechan-

ical room.

• High noise levels common with air-

cooled motors, which radiate noise

to the machine room and adjacent

areas.

• Shaft alignment problems that occur

with open-drive designs during start-

up and operation, when equipment

temperature variations cause ther-

mal expansion.

Positive pressure design

Positive pressure designs eliminate the

need for costly low pressure contain-

ment devices, reducing the initial cost

Features/Benefits (cont)

Table of contents

Page

Features/Benefits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Model Number Nomenclature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Capacity Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Physical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7,8

Options and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-11

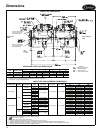

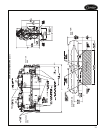

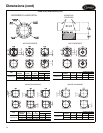

Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-14

Selection Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Performance Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-18

Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19,20

Typical Control Wiring Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Application Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22-24

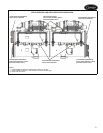

Typical Piping and Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Electrical Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26-28

Guide Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29-32