13

DVBR Series Direct Vent Gas Fireplace

20000584

TWL100

Twist Lock Pipe

3/12/99 djt

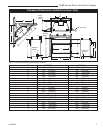

Male End

Female

End

Screw Holes

TWL100

Fig. 17 Twist-Lock pipe joints.

Twist Lock Pipes

When using CFM Corporation twist-lock pipe, it is not

necessary to use silicone to seal the twist-lock joints.

The only areas that need silicone are the collars on the

fireplace, the telescoping pipe (if used) and the hori-

zontal termination connection (when necessary). The

female (flared) end secures to the fireplace first with the

male end away from the fireplace.

To join the pipes together, simply align the beads of the

male end with the grooves of the female end, twisting

the pipe until the flange on the female end touches the

external bead on the male end. Secure the joints with

three (3) sheet metal screws. (Fig. 17)

To make assembly easier, apply lubricant (vaseline or

similar) on the male end of the twist-lock pipe.

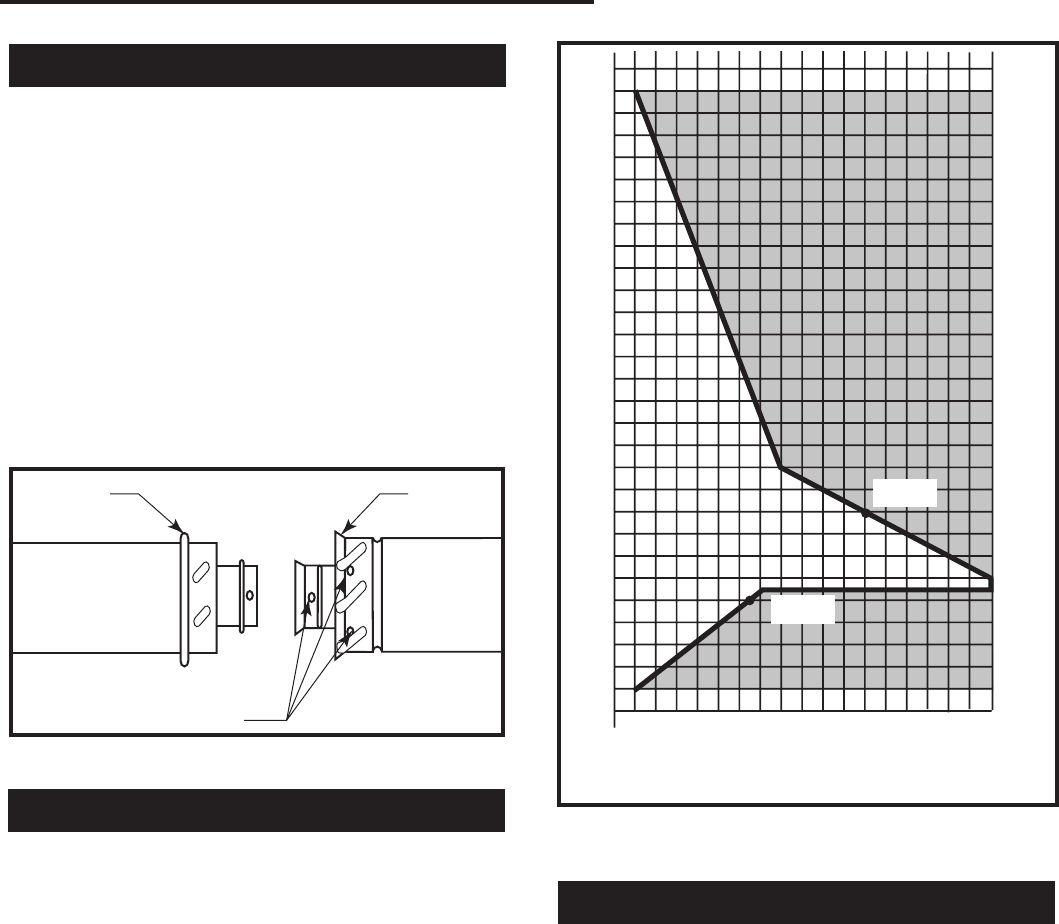

How to Use the Vent Graph

The Vent Graph should be read in conjunction with the

following vent installation instructions to determine the

relationship between the vertical and horizontal dimen-

sions to the vent system.

1. Determine the height of the center of the horizontal

vent pipe exiting through the outer wall. Using this

dimension on the Sidewall Vent Graph (Fig. 18),

locate the point intersecting with the slanted graph

line.

2. From the point of this intersection, draw a vertical

line to the bottom of the graph.

3. Select the indicated dimension, and position the

fireplace in accordance with same.

EXAMPLE A:

If the vertical dimension from the floor of the unit is 11

feet (3352 mm) the horizontal run to the face of the

outer wall must not exceed 14’ (4267 mm).

EXAMPLE B:

If the vertical dimension from the floor of the unit is 7’

(2133mm), the horizontal run to the face of the outer

wall must not exceed 8¹⁄₂’ (2590 mm).

Rear Wall Vent Applications

When installed as a rear vent unit this appliance may be

vented directly to a termination located on the rear wall

behind the appliance.

• Only CFM Corporation venting components are ap-

proved to be used in these applications (See ‘Venting

Components’ listed for different installation require-

ments).

• The maximum horizontal distance between the rear

of the appliance (or end of the transition elbow in a

corner application) and the outside face of the rear

wall is 20” (508mm). (Fig. 19, 20 )

• Only one 45° elbow is allowed in these installations.

• Minimum clearances between vent pipe and com-

bustible materials are as follows:

Top - 2” (51 mm)

Sides - 1” (25 mm)

Bottom - 1” (25 mm)

Refer to Page 19 for venting

requirements for snorkels.

Vertical Dimension from the Floor of the Unit

to the Center of the Horizontal Vent Pipe

Fig. 18 Sidewall venting graph. (Dimensions in feet.)

DV Graph

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

3

4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

eg: A

eg: B

Horizontal Dimension from the Outside Face of the

Wall to the Center of the Fireplace Vent Flange