6

20012301

Vermont Castings DVR28 Direct Vent Gas Fireplace

Sheet Metal

Screws (8)

Sheet Metal

Screws (4)

FP1785

Wall Mounting Bracket

Secured to Walll

DVR28

Fig. 6 Secure fireplace to wall mounting bracket.

High Elevations

Input ratings are shown in BTU per hour and are

certified without deration for elevations up to

4,500 feet (1,370m) above sea level.

For elevations above 4,500 feet (1,370m) in USA,

installations must be in accordance with the cur-

rent ANSI Z223.1/NFPA 54 and/or local codes hav-

ing jurisdiction.

In Canada, please consult provincial and/or local

authorities having jurisdiction for installations at

elevations above 4,500 feet (1,370m).

Gas Line Installation

When purging the gas lines, the front win-

dow frame assembly must be removed.

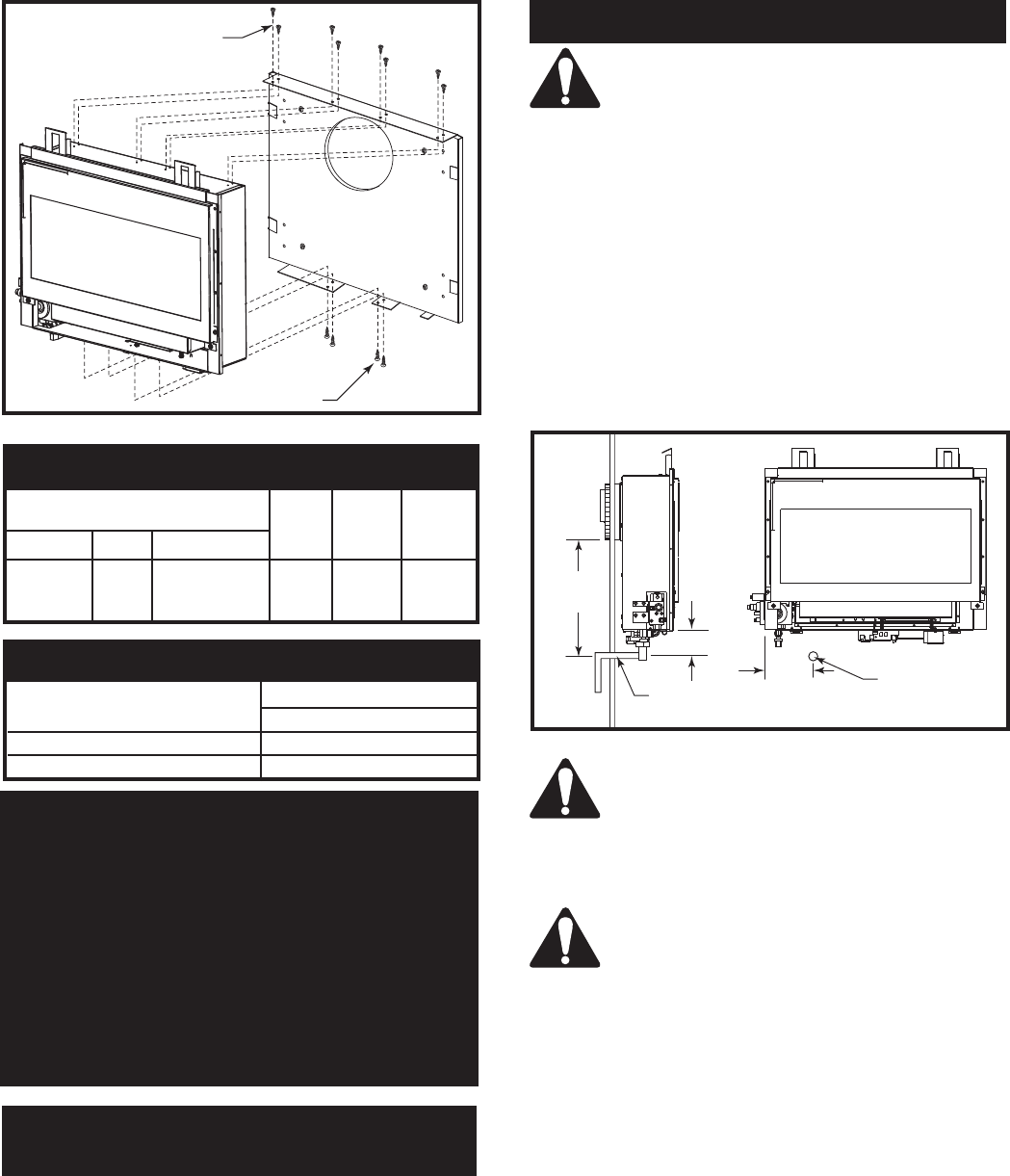

The gas pipeline can be brought in under the bottom of

the fireplace. The gas line connections will be covered

by bottom trim. Refer to Figure 7 for gas line dimen-

sions. Use 1/2” rigid pipe. When gas line is in place un-

der the fireplace, install supplied 1/2” FPT to 3/8” flare

brass fitting. Connect preinstalled flex line on fireplace

to brass fitting with 3/8” flare fitting on supply line.

The gas line connection can be made with 3/8” rigid

pipe or an approved flex connector. Since some munici-

palities have additional local codes, it is always best to

consult your local authority and the National Fuel Gas

Code, ANSI Z223.1/NFPA 54 in the USA or the CSA-

B149.1 installation code.

Remote ON/OFF Hi/Lo

Wall Mounted Transmitter

The DVR28 is equipped with a wireless transmitter. No

wires are required.

Always check for gas leaks with a mild

soap and water solution applied with a

brush no larger than 1” (25 mm). Never

apply soap and water solution with a spray

bottle. Do not use an open flame for leak

testing.

The fireplace valve must not be subjected

to any test pressures exceeding 1/2 psi.

Isolate or disconnect this or any other gas

appliance control form the gas line when

pressure testing.

The gas control is equipped with a captured screw type

pressure test point, therefore it is not necessary to pro-

vide a 1/8” test point up stream of the control.

When using a flex connector use only approved fittings.

Always provide a union when using black iron pipe

so the gas line can be easily disconnected for burner

servicing. See gas specification for pressure details and

ratings.

The fireplace valve must not be subjected to any test

pressures exceeding 1/2 psi. Isolate or disconnect this

and any other gas appliance control from the gas line

when pressure testing.

Inlet Minimum 5.5” w.c.

Inlet Maximum 14.0” w.c.

Manifold Pressure 3.5” w.c.

Gas Inlet and Manifold Pressures

Natural

12”

(318 mm)

6”

(152 mm)

FP1787

gas line install

3/07

1”

(32 mm)

Gas Line

Through Wall

Gas Line

Opening in

Wall

FP1787

Fig. 7 Recommended gas line installation.

Max. Min. Air

Input Input Shutter

Model Fuel Gas Control BTU/h BTU/h Setting

1/8”

DVR28IN Nat. Millivolt Hi/Lo 18,500 16,500 open

on sides

Gas Specifications