One Conair Drive ● Pittsburgh, PA 15202 ● 412-312-6000 ● FAX 412-312-6227 ● www.conairnet.com

0

0

0

0

0

0

0

0

0

B

A

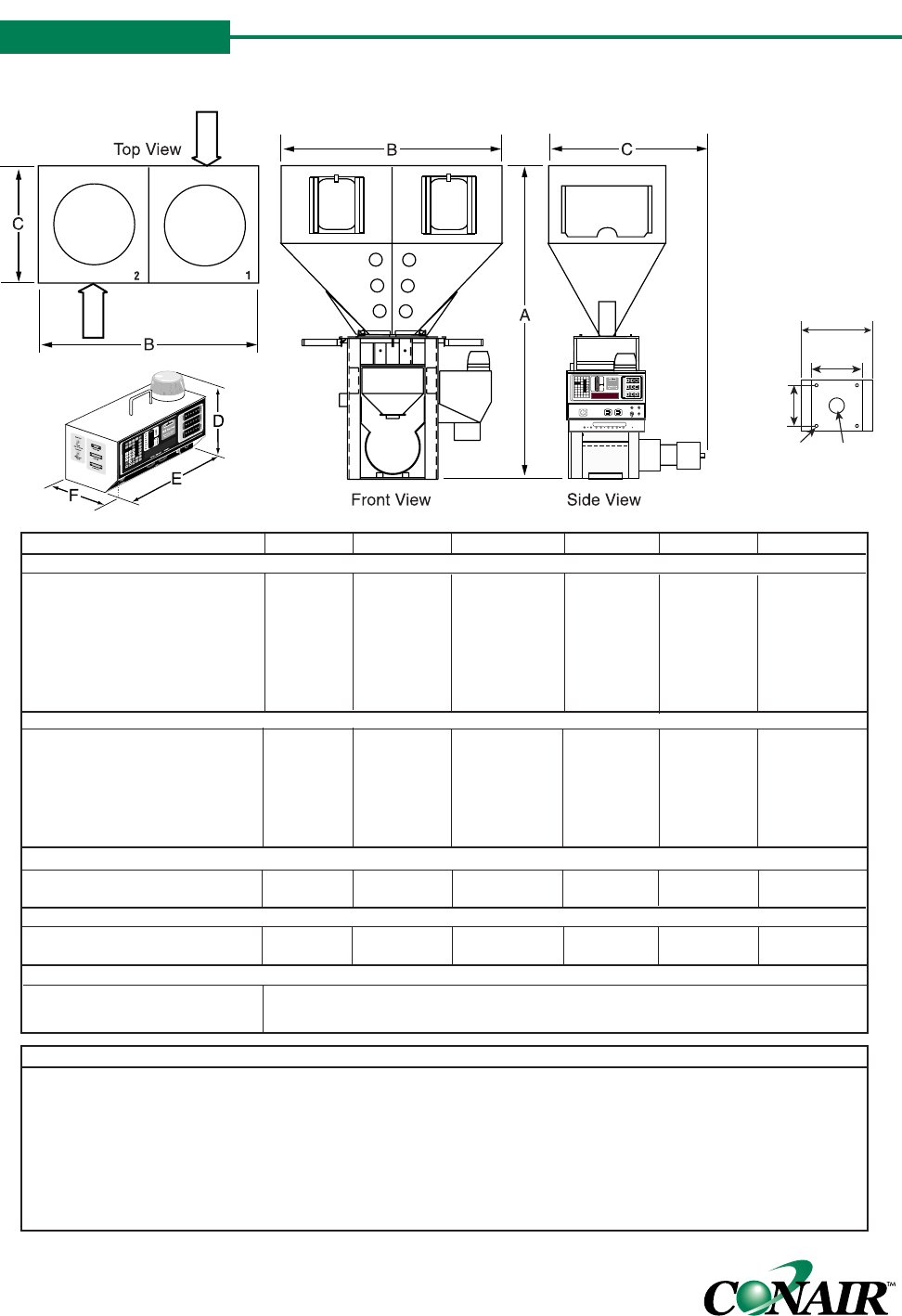

GRAVIMETRIC BATCH BLENDERS

WSB 220 and 420 Models

SPECIFICATION NOTES:

Each bin compartment will support a 12-inch to 15-inch loader or vacuum receiver.

*

Throughput rates are based on using no more than 5% additive or colorant material total in either the CAF3 compressed

air or F03 auger feeder. Always refer to the selection guide for specific throughput information.

† The optional butterfly control flow control valve adds 3.5 in. {88.9 mm} to the total height.We recommend using the flow

control valve when mounting the blender to a stand, surge bin or hopper.

‡ Feeders will increase width and depth dimensions. Please refer to feeder specifications.

§ Each additional auger feeder requires an additional 1 amp @ 120V or 0.5 amps @ 240V.

MODELS WSB220 WSB221 WSB222 WSB420 WSB421 WSB422

Performance characteristics

Batch size lbs {g} 4.4 {2000} 4.4 {2000} 4.4 {2000} 8.8

{4000}

8.8

{4000}

8.8

{4000}

Maximum throughput

lbs/hr {kg/hr}* 1239 {562} 575 {261} 540 {245} 1966 {892} 700 {318} 680 {308}

Bin capacity - each ft

3

{liter}

2.0 {56.6} 2.0 {56.6} 2.0 {56.6} 2.0 {56.6} 2.0 {56.6} 2.0 {56.6}

Maximum number of materials 2 3 4 2 3 4

Number of discharge valves 2 2 2 2 2 2

Number of additive feeders 0 1 2 0 1 2

Control software (# of components) 4 or 12 4 or 12 4 or 12 4 or 12 4 or 12 4 or 12

Dimensions inches {mm}

A - Height above mounting plate

†

48 {1217.9} 48 {1217.9} 48 {1217.9} 54 {1370.3} 54 {1370.3} 54 {1370.3}

B - Width

‡

34.4 {873.8} 34.4 {873.8} 34.4 {873.8} 34.4 {873.8} 34.4 {873.8} 34.4 {873.8}

C - Depth

‡

24.75 {628.6} 24.75 {628.6} 24.75 {628.6} 24.4 {619.8} 24.4 {619.8} 24.4 {619.8}

D - Controller height 11.25 {285.75} 11.25 {285.75} 11.25 {285.75} 11.25 {285.75} 11.25 {285.75} 11.25 {285.75}

E - Controller width 12.25 {311.15} 12.25 {311.15} 12.25 {311.15} 12.25 {311.15} 12.25 {311.15} 12.25 {311.15}

F - Controller depth 8.19 {208.03} 8.19 {208.03} 8.19 {208.03} 8.19 {208.03} 8.19 {208.03} 8.19 {208.03}

Weight lbs {kg}

Installed 220 {100} 260 {118} 300 {136} 245 {111} 285 {129} 325 {147}

Shipping 325 {147} 265 {120} 405 {183} 350 {159} 390 {177} 430 {195}

Voltage Total amps

§

120V/1 phase/50-60 Hz 4.8 4.8 4.8 4.8 4.8 4.8

240V/1 phase/50-60 Hz 2.5 2.5 2.5 2.5 2.5 2.5

Compressed air requirements

Discharge valves 80 psi @ 0.2 ft

3

/min. {5.5 bars @0.09 liters/sec}, 1/4 in. NPT fitting

Compressed air feeder 40 psi @ 2 ft

3

/min. {2.8 bars @0.94 liters/sec}, 1/4 in. NPT fitting

(4) 9/16 in.

{14.3 mm}

diameter

bolt holes

3 in. {76.2 mm}

diameter

through hole

8 in.

{203.2 mm}

square bolt

pattern

10 in.

{254 mm}

14 in.

{355.6 mm}

MOUNTING INTERFACE

CONTROL

SPECIFICATIONS

TPBS002/1199

IBO4

APPENDIX B