10

10

Burner Ignitors

Under certain cooking or cleaning conditions,

your cooktop ignitors may become coated with

or corroded by food deposits, splattered grease

or cleaning agents. This condition can cause

erratic or continuous sparking. Keeping the

ignitors clean and dry will help to reduce this

problem.

To avoid unnecessary and costly service

calls, the homeowner should perform periodic

cleaning of the ignitors.

An Ignitor Cleaning Brush is enclosed for your

use in cleaning the cooktop ignitors.

To clean the ignitors:

1. Be sure burners are cool to the touch.

Remove the grate, burner cap and burner

rings.

2. Brush completely around the ignitor,

including over and under the edge of

the metal cap and base. Use care while

cleaning here. The ignitor is porcelain and

can be fragile.

3. DO NOT USE WATER when cleaning the

ignitors. If a liquid must be used to clean

the ignitor effectively, use a small amount

of rubbing alcohol.

4. After cleaning, reinstall the burner ring,

burner cap and grate. Make sure the brass

burner ring is properly seated into the

burner base.

5. Test the burners. If erratic clicking is still

present, make sure the ignitor is completely

dry. If the unit still exhibits problems after

drying, call your local DACOR Authorized

Servicer.

Self-Cleaning

The electric door latch is a convenient safety

feature. The door latch is automatically activated

after selecting the Self-Clean mode. The latch

ensures that the oven door cannot be opened

while the interior oven temperatures are unsafe

to the user.

The oven features an automatic pyrolytic

Self-Cleaning cycle to eliminate the need for

difficult and time-consuming manual scrubbing

of interior surfaces. During this cycle, the oven

reaches extreme high temperatures to burn off

soil and deposits. A powder ash residue is left

in the bottom of the oven after completion of the

Self-Clean cycle.

The Self-Clean time is variable from 2 to 4

hours to offer flexibility in handling various soil

conditions. A 2-hour cycle normally handles a

moderately soiled oven, whereas a 4-hour cycle

is recommended for a heavily soiled condition.

The Self-Clean cycle can also be delayed to

start at a later time if desired.

IMPORTANT:

1. It is normal for some smoke to be

emitted during the first few Self-Clean

cycles.

2. Popping sounds are normal during Self-

Clean cycles. These sounds are caused

by the expansion and contraction of

metal surfaces during heat-up and cool-

down.

3. Do not line the oven with aluminum

foil or other materials. These items can

melt or burn during a Self-Clean cycle,

causing permanent damage to the oven.

WARNINGS:

1. DO NOT OPERATE THE OVEN LIGHTS

IN THE SELF-CLEAN MODE.

2. Do not touch the outside surfaces of the

oven during the Self-Clean cycle.

3. Do not use commercial oven cleaners

inside the oven. Use of these cleaners

can produce hazardous fumes or can

permanently damage the porcelain

finishes.

Prepare the oven for Self-Cleaning by

following these steps:

1. Clean soil from the oven front frame area

and the oven door outside of the door

gasket. Cleaning the door gasket by hand

can cause it to bend or move. A tight door

seal is essential for proper baking and

Self-Cleaning. Rinse surfaces well with a

solution of vinegar and water, then wipe

dry. Heavily soiled areas may be cleaned

with a non-scratching scouring pad.

2. Remove the broiler pan, all cookware,

utensils and other loose items from the

oven chamber. Also, remove all oven

racks and the convection fan filter to

prevent them from permanently discoloring.

However, to clean stubborn particles in the

convection filter you may elect to simply

leave it in place during self-clean. The filter

will discolor due to the high heat, but this

will not harm the filtering capabilities.

IMPORTANT:

If racks are left in the oven during a Self-

Clean cycle, it will affect their ability to slide

in and out easily. Polish the rack edges with

a soapy steel wool pad, then apply a small

amount of vegetable oil to the edges so that

the racks will slide more easily.

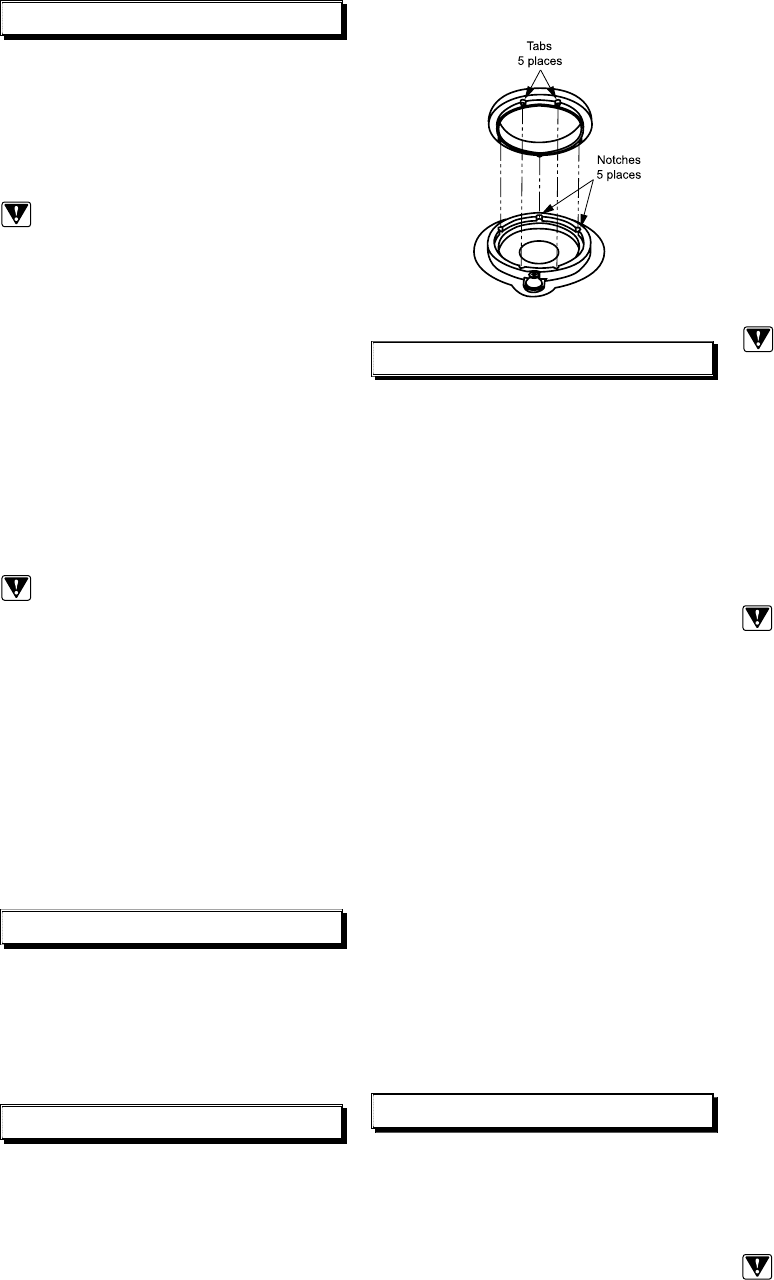

Burner Bases

The brass burner rings spread the flame evenly

around the burner perimeters. The burner rings

must seat properly in the burner bases to enable

proper cooktop operation. To ensure proper

seating, five positioning tabs have been placed

on the bottom of each burner ring to slide into

corresponding notches in the fixed burner base.

Burner Rings

The burner rings are made of brass. To remove

the burner ring, first lift off the porcelain burner

cap. The burner ring may then be removed from

the burner base. Soak the burner ring in a warm

solution of hand dishwashing liquid and water,

then rinse well with clean water. Dry the burner

ring thoroughly before placing it back on the

burner base.

Burner Rings

Stubborn stains may be removed by applying a

metal polishing compound.

WARNING:

Never block the holes in the control panel

below the knobs. This will impair the flow of

combustion air and adversely affects burner

operation, possibly creating a hazardous

condition.

The knobs should be washed regularly in

warm, soapy water. Hand dishwashing liquid

is excellent for this task. Knobs should be

removed by gently pulling them straight off of

the valve shafts. The spill protector rings should

be cleaned in place. Use caution to avoid

introduction of moisture into the control panel.

To replace knobs, align the “D-shaped” opening

at the bottom of the knob with the “D-shaped”

valve shaft, then carefully press the knob onto

the valve shaft.

IMPORTANT:

1. Turn the knobs to the “OFF” position

prior to removing them from the valve

stems.

2. The cooktop should never be operated

without the knobs and spill protector

rings in place.

3. Do not soak the knobs and spill

protector rings in water or place them in

the dishwasher.

4. Do not expose the knobs or spill

protector rings to direct flame, hot

utensils, or other sources of heat.

5. Do not use abrasive or corrosive

cleaners or applicators. They could cause

permanent damage.

Knobs and Spill Protector Rings

The control knobs provided with these ranges

are designed for ease of use and longevity. The

“D” shaped design of the knob shaft ensures

proper orientation when re-installing the knob.

Beneath each knob, a spill protector ring

prevents liquid spills from entering the control

panel.