4

5

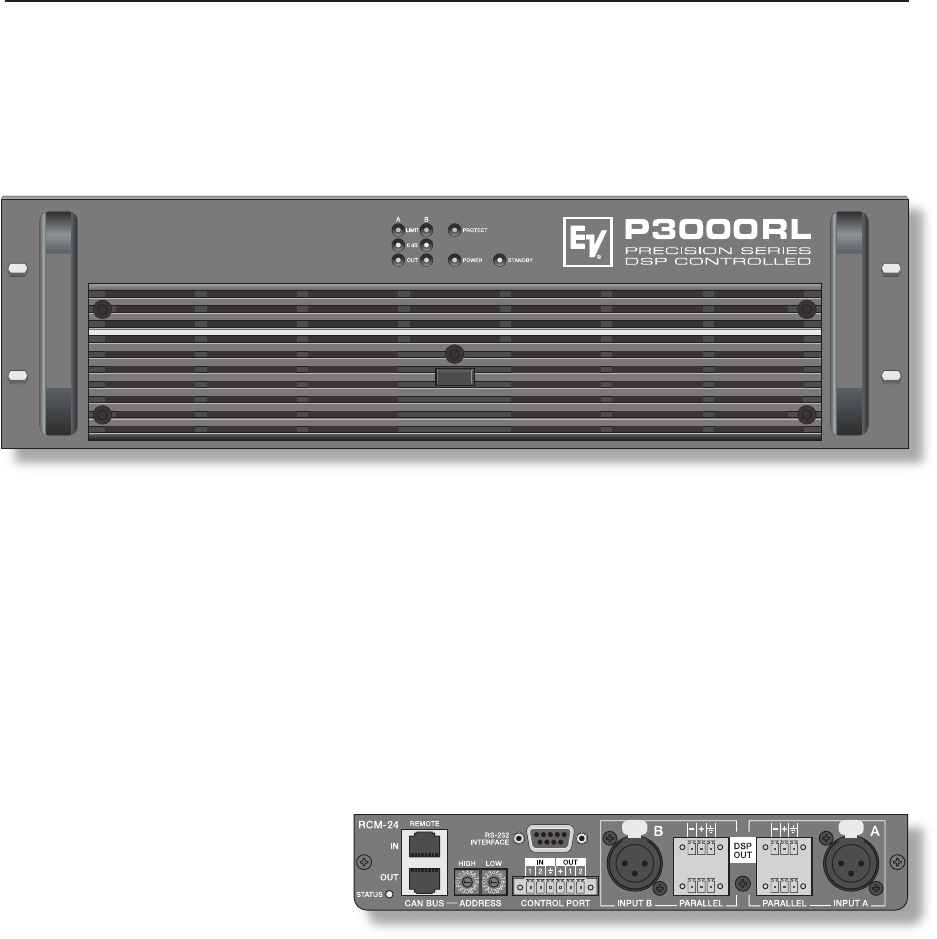

Congratulations! With buying an Electro-Voice PRECISION SERIES power amplier you have chosen

an appliance that employs the most advanced technology.

P-Series power amps combine outstanding audio performance, highest reliability and operational

stability. Each power amplier employs an RCM-24 Remote Control module allowing centralized

conguration, control and monitoring of all relevant power amp parameters (like output current, output

voltage, load impedance, etc.).

The gapless protection circuitry concept not only prevents the power amp itself but also the connected

loudspeaker systems from being damaged. These extensive protections include Dynamic Audio

Limiters, DC/HF-Protections, Back-EMF-Protection, Inrush Current Limiter, Short Circuit Protection

and of course Thermal Overload Protection for the output transistors and mains transformers.

Four-speed high performance fans guarantee outstanding thermal stability at absolute low running

noise. The ventilation is directed front-to-rear allowing trouble-free operation even in smaller amp-racks.

Comprehensively dimensioned power supply units with low-leakage toroidal transformers provide

extensive headroom far above the stated nominal power.

Mechanical construction and workmanship also comply with the highest precision manufacturing

standards. The rigid sheet steel chassis resists even the most wearing tour operation.

The RCM-24 provides full-size

overview of the system’s entire status

and control over all relevant system

parameters at any time.

The RCM-24 module allows integration into a Remote Control Network consisting of up to 250 power

amps. The Windows Software IRIS – Intelligent Remote & Integrated Supervision – allows controlling

and monitoring an entire PA-system from a single or several PCs. Any operational status like initial

power-on status, temperature, modulation, limiting, activation of protections, deviation in the load

impedance, etc., are centrally registered and displayed, which provides the opportunity to take specic

measures prior to the occurrence of critical operational states. Programming an automatic response for

exceeding or falling below specic limits is possible as well. All parameters, e.g. power-on/off, levels,

muting, lters, etc. can be controlled in real-time and saved in any power amp.

Monitoring the connected loudspeaker systems is performed through measuring output currents

and –voltages of the two power amplier channels. Each time the signal falls below or exceeds set

limit values is immediately indicated and logged, thus detecting and indicating short circuits and line

interruption during normal operation. The integrated impedance test function allows more precise

checking the connected loudspeaker systems. The integrated signal generator is employed together

with the current/voltage testing to measure the connected loudspeakers’ and cable’s impedance

plus over the entire frequency range. The resulting impedance graph is displayed on the PC-screen.

Comparing the measured impedance progression to a reference value is possible at all times, which

allows recognizing even the slightest loudspeaker defects or irregularities.

DESCRIPTION