IP258

6

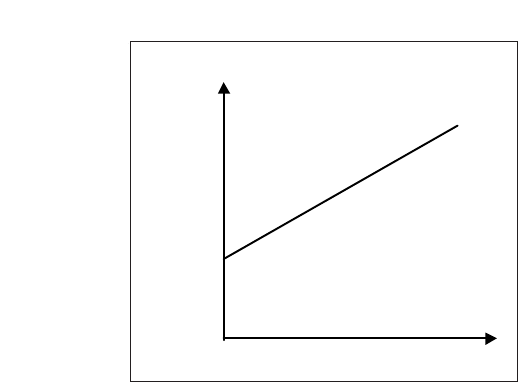

The relationship between attenuation and suspended solids is

shown graphically in Figure 2. Calibration of the unit involves

adjustment of the zero point, by setting up the sensors in

clean liquid (supernatant), and then setting the slope of the

straight line graph, either according to past data or from site

samples.

In the memory of the MSM400 there is information on various

slurry types, to enable simple initial set-up. More accurate

adjustment can then be made once site samples have been

taken.

Zero Ref

Attenuation

(dB)

S

l

o

p

e

% Solids

Figure 2 : Ultrasonic Attenuation versus

Suspended solids

SLURRY CHARACTERISTICS

The relationship between the measurement of ultrasonic attenuation and the percentage solids of a particular slurry

type is dependent on the density of the slurry particles and their average size distribution. This is known from

experience for most slurry types, and is expressed as a number, which is the ultrasonic attenuation in deciBels (dB),

per mm gap between sensor faces, per one percent suspended solids.

Calibration:

The Mobrey experience with using ultrasonics for suspended solids monitoring has been developed over 25 years.

Calibration systems for the MSM400 use this experience, allowing the plant operator to choose whether to set up the

unit based on Mobrey site and slurry experience, or whether to take site samples to fine tune that data to suit the

specific site conditions. The MSM400 is versatile enough to allow simple or complex calibrations.