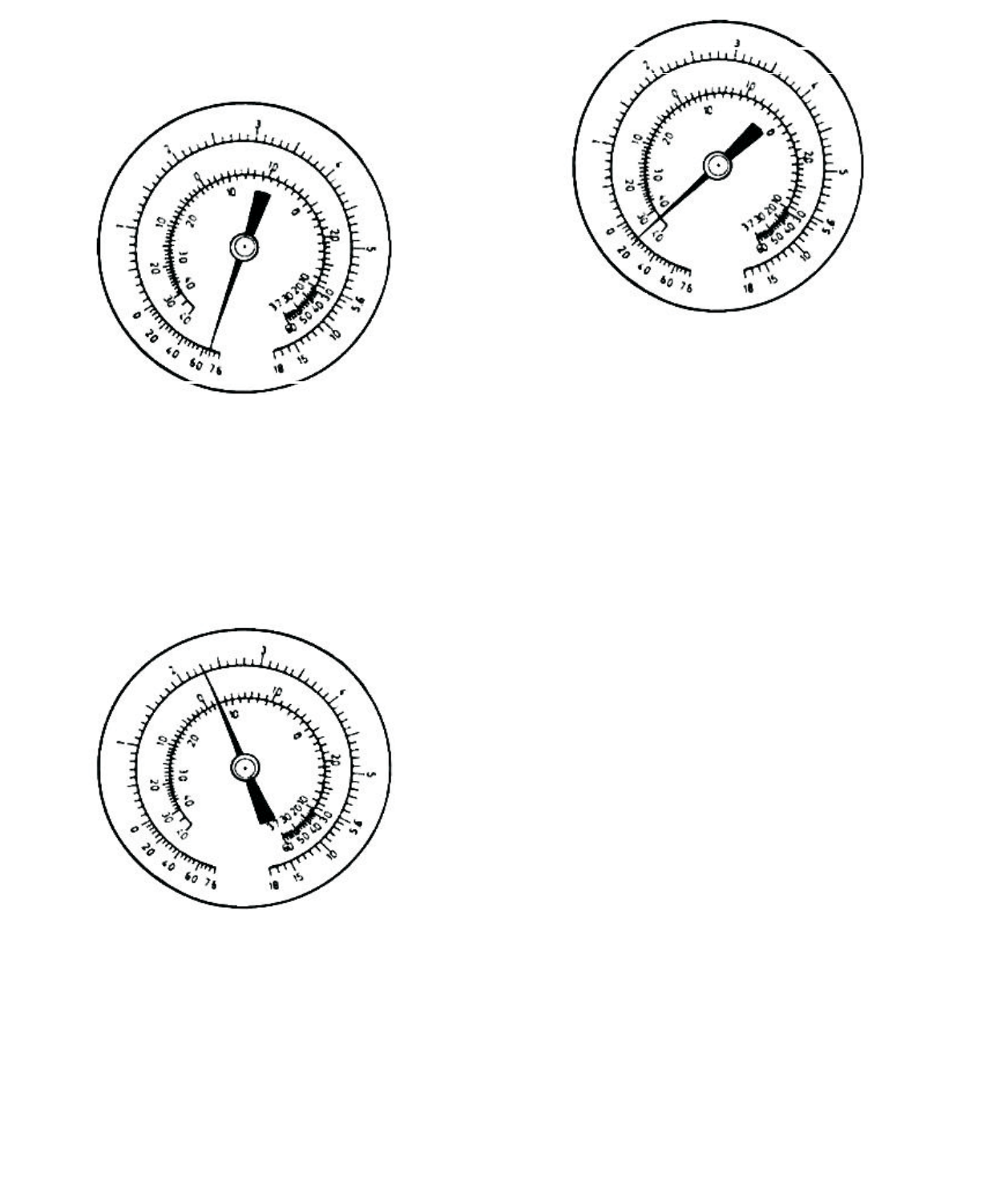

Examples of trouble-shooting using a manometer on the suc-

tion side (process pipe) and a service valve:

1

. The system is blocked.

The suction pressure is very low.

Pressure equalizing takes place very slowly or not at all.

Cause: Ice blockage in the capillary tube at the filter

or blockage in the system for other reasons. See trouble-

shooting chart.

2. No compressor capacity.

The suction pressure is high.

The suction pressure does not change appreciably when

the compressor stops.

If a slight defect in the compressor is suspected, this can be

checked with a volumetric gauge.

See Section 4.1.: Opening the Refrigerating System for

Repairs and Section 4.3.: Replacing the Compressor.

3. Leakage in the system.

The manometer indicates insufficient suction pressure.

The pressure equalizing time is short.

The equalizing pressure is lower than would be expected.

Ensure that the equalizing pressure is sufficient for leak

detection.

14.