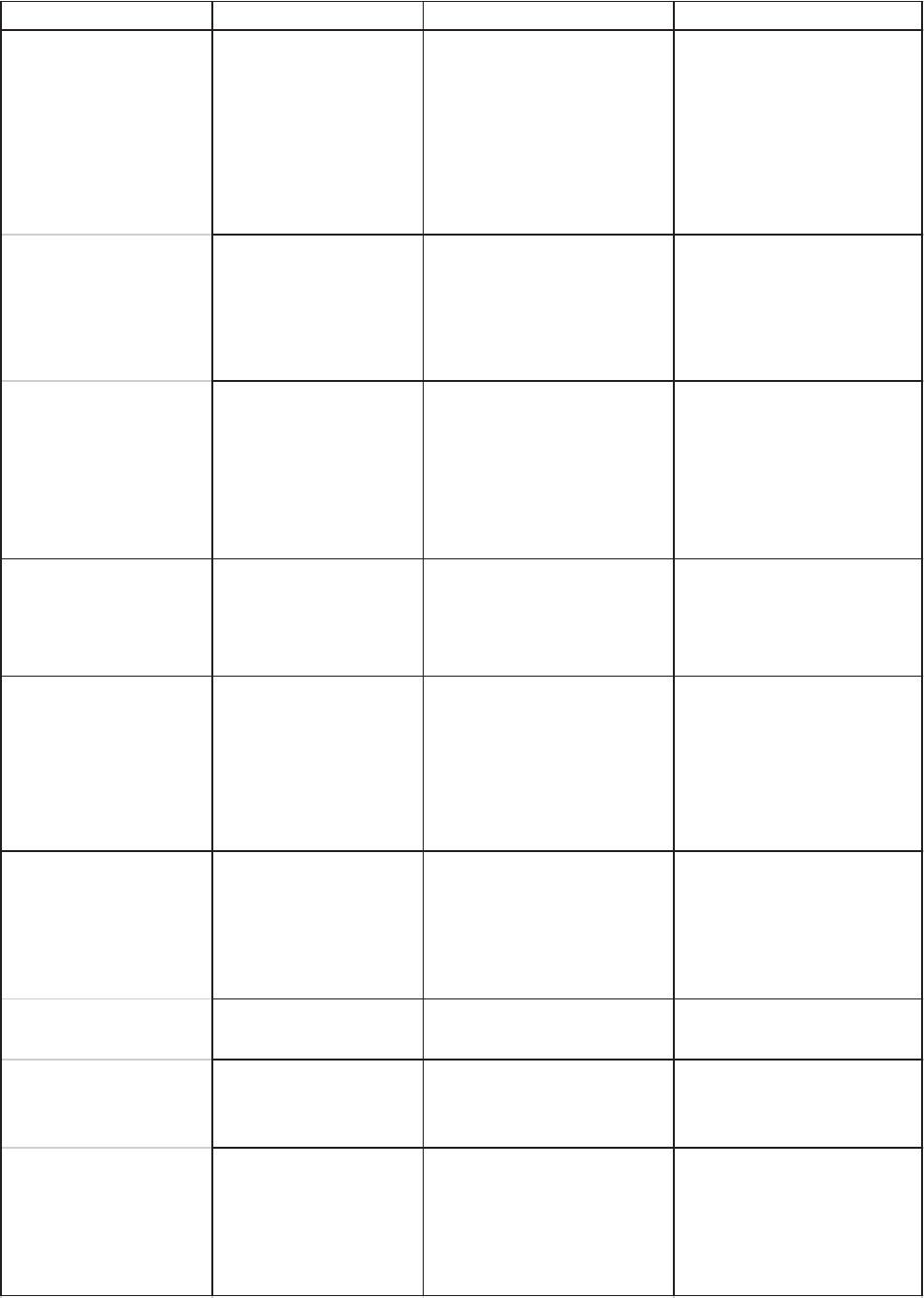

Disturbance Cause Trouble-Shooting Remedy

Oil present in system

after horizontal

transport.

Question user about mode

of transportation and time

interval between

installation and start-up.

Let unit stand for several

hours at warm

temperature and try to

start again. If compressor

does not start, open the

system and blow through

with N2.

Locked rotor (fault in

compressor).

Check that compressor

hums and picks up total

starting current. Open

system and blow N2

through system.

If system (filter) is not

blocked, replace

compressor.

Ambient temperature

very low. Oil in

compressor too cold,

possibly in connection

with undervoltage.

Measure ambient

temperature. Measure

voltage.

Find a better location for

unit. Condenser can be

insulated if necessary, but

DON’T FORGET to

remove again if ambient

temperature increases.

Compressor tries to

start but does not

always succeed on

first attempt.

Can be normal.

Ventilation is perhaps

insufficient.

Measure the temperature

of compressor housing

(max. 110°C) and filter

(max. 70°C).

Find a better location for

the unit.arrange ways for

a better ventistat.

Refrigerate and/or

freeze normally.

Compressor tries to

start but does not

succeed on first

attempt.

Standstill time for

compressor is too

short.

Check for snug fit of

doors. Time standstill

period for compressor.

If standstill time is too

short, replace thermostat.

Compressor runs

continuously. Unit

refrigerates/freezes

normally or too much.

Thermostat phial is

incorrectly installed.

Check location ofphial. Correct the fault. Cutout

temperature can be raised

by giving the phial a

greater surface contact

with the evaporator.

Ice formation around

thermostat phial.

Check for snug fit of

doors

Inform user to defrost

unit.

Thermostat set too

low.

Turn thermostat knob

counter-clockwise.

If compressor stops,

inform user about function

of thermostat.

To be continued on

the next page.

Ice formation in phial

tube.

Defrost unit. Remove

thermostat phial, dry

thoroughly and replace.

Repeat until the phial is

dry. Sealwith putty.

4.