2. MAKING REPAIRS TO THE REFRIGERATING

SYSTEM

2.1. Opening the Refrigerating System with Refrige-

rant R600a (Isobutane) for Repairs

The Possibility of Fire/Explosion exists

Therefore, it is important to pay attention to the following points

before commencing repairs of the refrigerating system:

1. The serviceman is familiar with the dangers related to

combustible refrigerants and knows how to use the per-

sonal protection equipment.

2. There is no risk of sparks forming near the workroom.

3. Do not smoke or use naked flame or other means of heat.

Therefore, no soldering on the system is allowed.

4. Electrical appliances to be used during the service must

not produce sparks.

5. See that there is good ventilation in the workroom.

6. Do not let the refrigerant flow into basement openings,

low lying rooms, sewer systems, etc. as R600a is heavier

than air.

7. Safety rules for handling, storage and transport of com-

bustible refrigerant applicable in the various countries must

be followed.

If a hermetic refrigerating system is to function correctly and

have a reasonably long life, it is essential that the number of

impurities present in the system i.e. moisture, foreign gases,

dirt, etc. is kept at a minimum.

This fact must be taken into consideration when repairs are to

be made, and the necessary precautions must be taken.

If there is any risk at all of finding refrigerant near or inside the

cooling/freezing unit, it must be found before commencing the

repairs. Note that some leak detectors must not be switched

on in the workroom.

Before commencing repairs, make sure that an exact diagno-

sis of the problem has been made.

Mount a service valve or drilling tongs on the charging pipe

(process pipe) and confirm the diagnosis with a suction ma-

nometer. Close the valve.

First Evacuation

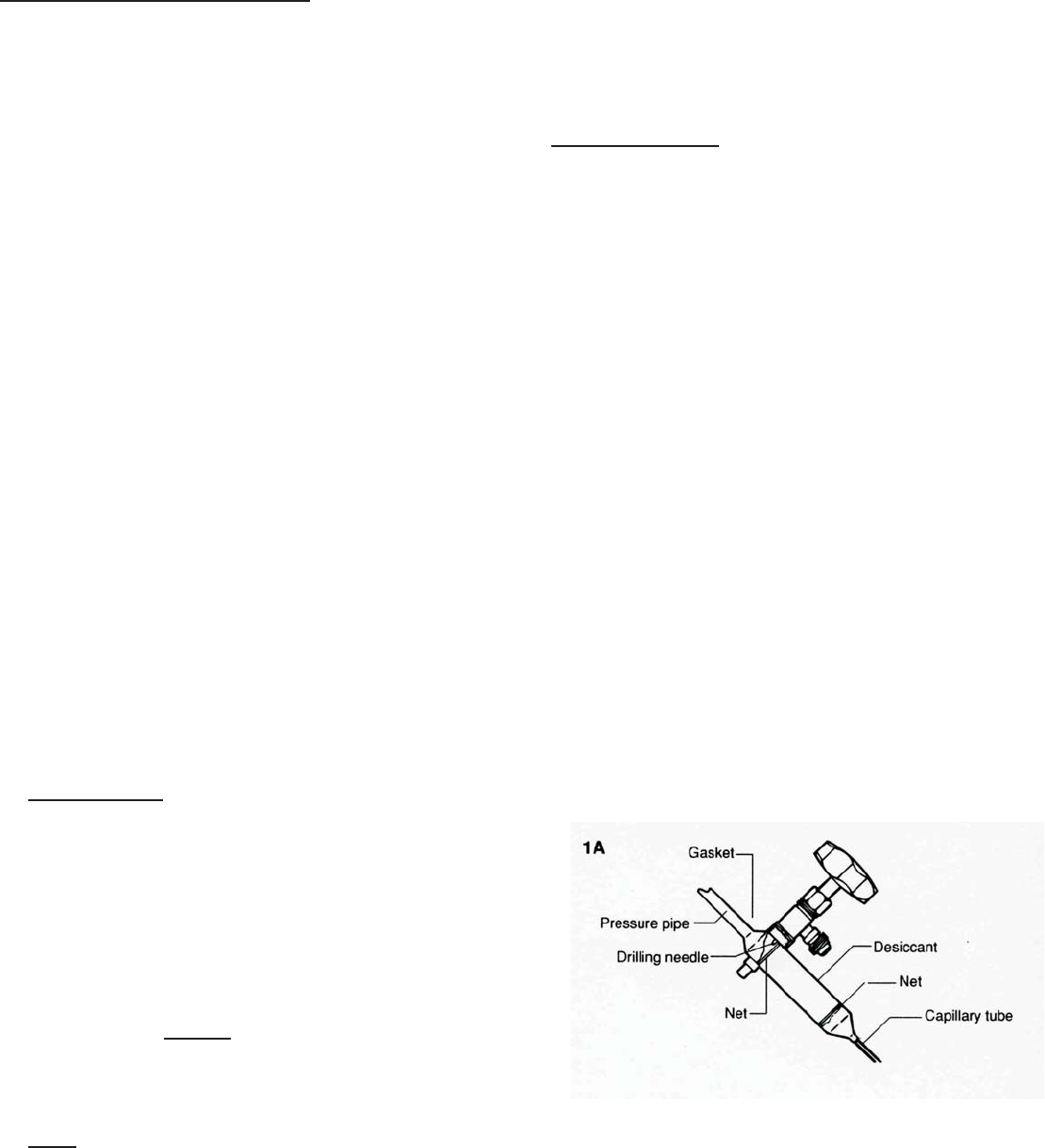

After thorough cleaning of the spot where the gasket of the

drilling tongs is to seal and adjusting of the tongs into filter

size, the drilling tongs are mounted on the top of the filter drier

just below the curve (at the pressure pipe - see figure 1A.)

and the drilling is carried out- see figure 1.

Mount the hose on the threaded branch of the drilling tongs.

The hose is carried outside (see figure 2A). Thereafter, the

valve on the drilling tongs is opened (see figure 2), and the

refrigerant will pressure equalize through the hose situated

outside.

If the compressor does not

need to be replaced, the oil is

degassed in the compressor by letting the compressor run for

about 1 minute.

The compressor is started at the thermostat, after the area

around the thermostat has been found free from refrigerant.

Never

start the compressor under vacuum, it would risk dam-

age to the motor.

The system can then be blown through with nitrogen (see sec-

tion: The Blowing Process). The valve is closed at the filter

drier (see figure 3), the hose is dismounted and mounted on

the vacuum pump outlet on the oil separator - see figure 4.

Connect the hose of the filling station to the valve on the filter

drier and open the valve - see figures 5 and 6.

The refrigerating system is now ready for the first evacuation.

Evacuate to a pressure of approximately 5 mbar. After the first

evacuation, the valves are closed at the filter drier (9), at the

vacuum gauge (10), for the filling station (11), for the vacuum

pump (12), and the spherical valve (18) is closed.

The Blowing Process

Connect dry nitrogen (N2) (8) to the valve on the charging pipe.

Open the valve on the charging pipe and on the nitrogen tank

(14), regulate the working pressure with the reducing valve

(15) and equalize the pressure into the system.

Thereafter, the system, the filling station and the vacuum pump

are thoroughly blown through by opening the valve on the drill-

ing tongs at the filter drier (see figure 9) for the filling station

(11) and the valve for the vacuum pump is opened slowly (12).

Open the system by cutting off the capillary tube using capil-

lary tube scissors (see figure 13), so that burrs and deforma-

tion of the tube are avoided. Cut out the filter drier with a pipe

cutter.

Blow dry nitrogen (N2) through the system. The blowing pro-

cess allows the localization of any obstructions in the piping.

Investigate the dismounted filter as well for possible block-

age.

Any leakages can be remedied and components remounted

(see sections 2.2.: Replacing the Filter Drier, 2.3.: Replacing

the Compressor and 2.4.: Replacing the Evaporator).

When transporting dismounted compressors, the connecting

branches must be sealed with a tube joining system.

Mount a service filter, which is larger than the filter originally

used (as specified in the spare parts list). The filter drier must

be hermetically sealed until it is mounted.

The refrigerating system is prepared for assembly using a tube

joining system.

Mounting of Drilling Tongs on Filter Drier

15.