2.3. Replacing the Compressor

If trouble-shooting in the electric circuit or volumetric

measurements indicate that the compressor is defective, a new

compressor must be installed.

The following procedure is to be used:

Ensure that the new compressor is ready for installation.

Replace the electrical equipment.

Clean a good area of the pipes at the compressor branches

with a wire brush. This makes it easier to solder on the new

compressor and prevents contamination inside the pipes.

Remove the filter. Open the process pipe and blow dry nitrogen

(N2) through the system. Cut off the pipes approx. 2cm from the

compressor branches using a pipe cutter. Plug the pipes.

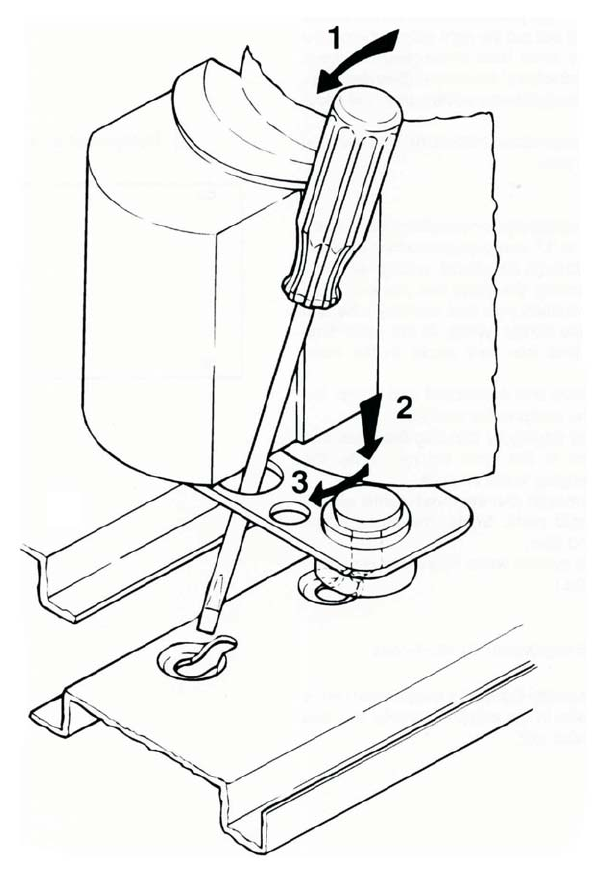

The dismounting of the compressor is carried out as shown in

the diagram:

1. Insert a robust screwdriver or similar tool through the hole

in the base plate and press against the compressor track

in the direction of the arrow.

2. Press the bolt downwards to free it from the attachment

hole.

3. Release the bolt by pressing in the direction of the arrow.

When mounting the new compressor, carry out the above

steps in the reverse order.

28.