2.2. Replacing the Filter Drier

Some moisture and impurities will always be accumulated in

the filter drier, both from residue left in the system after

installation and from contamination given off by the compres-

sor, pipe system and refrigerant. When repairs are made to the

refrigerating system, the filter will often be unable to absorb the

extra contamination which results, and ice blockage and

contamination of the capillary tube can result.

It is therefore important to note that REPAIRS MADE TO THE

REFRIGERATING SYSTEM HAVE NOT BEEN CORRECTLY

CARRIED OUT UNLESS THE FILTER DRIER HAS ALSO

BEEN REPLACED.

The following procedure should be used:

Open the refrigerating system by breaking off the capillary tube

approx. 5cm after the filter drier (use special-purpose pliers or

capillary tube scissors).

Discharge the refrigerant. In case of recovery of refrigerant -

see Section 2.1.1. + 2.1.3.

Cut out the filter using a pipe cutter.

THE FILTER MUST NOT BE SOLDERED OFF, AS ANY

MOISTURE COLLECTED IN THE FILTER WILL EVAPO-

RATE BACK INTO THE SYSTEM.

Open the system at the process pipe and blow dry nitrogen

(N2) through the system. In case of recovery of refrigerant - see

Section 2.1.1. + 2.1.3.

Install an outsize service filter (as specified in the spare parts

list).

Ensure that the capillary tube does not touch the compressor

when the filter is positioned.

Should this happen, the flow through the capillary tube can be

reduced (moisture barrier). This problem can be confused

with

slight under-filling of the system.

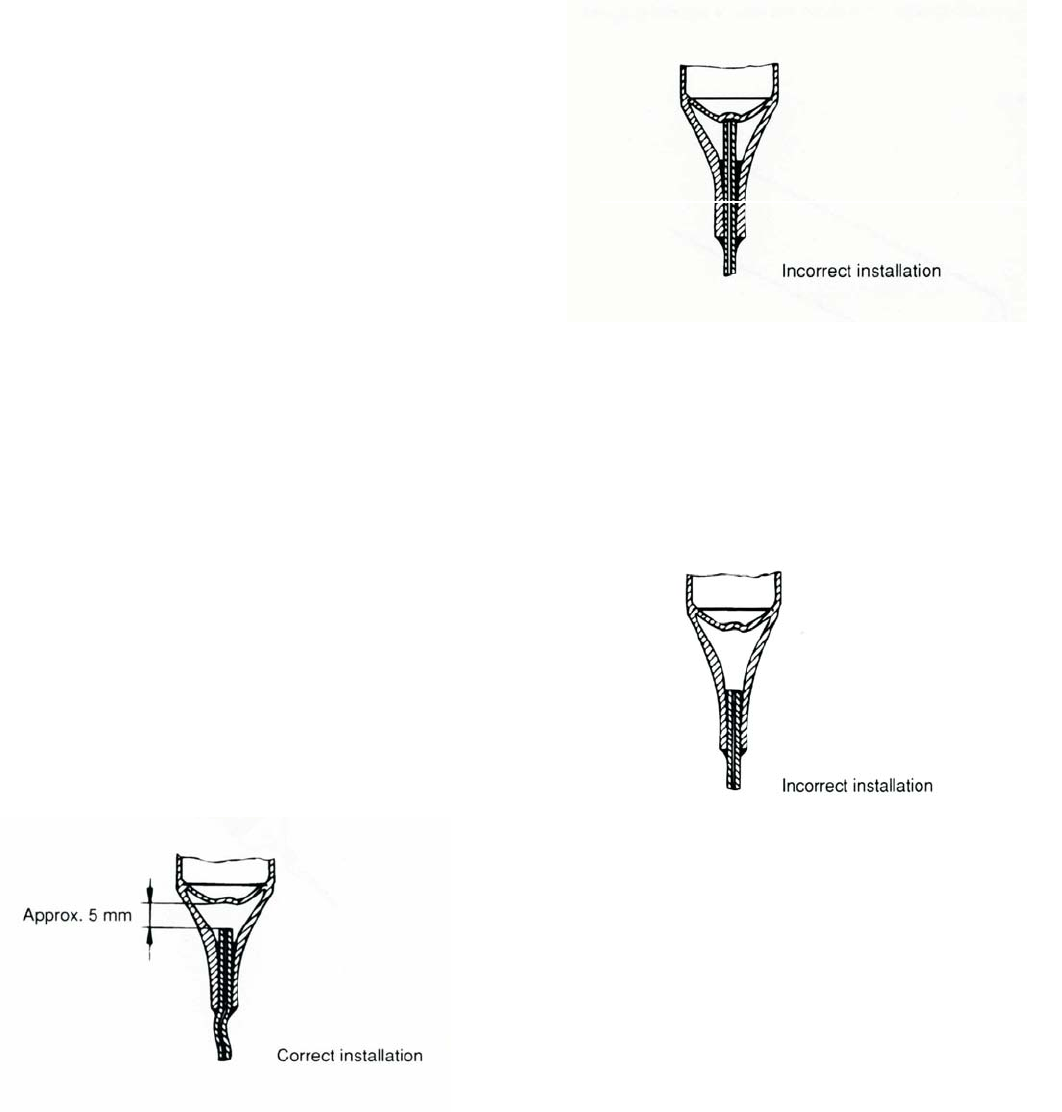

This filter drier has been installed correctly.

Special-purpose pliers have been used to make a wave in the

capillary tube.

The filter drier shown here has been installed incorrectly, with

the capillary tube touching the filter net. The end of the tube is

not free, and the resistance is thus increased. The tube will

become completely blocked after a period of use. Special-

purpose pliers should therefore be used.

Here the capillary tube has not been inserted far enough into

the filter. This will increase the risk of the tube becoming

plugged with flux or silver during soldering. The risk of the tube

becoming plugged during operation is also high, as circulating

particles will be led directly down into the capillary tube.

Special-purpose pliers should therefore be used.

26.