Page 3

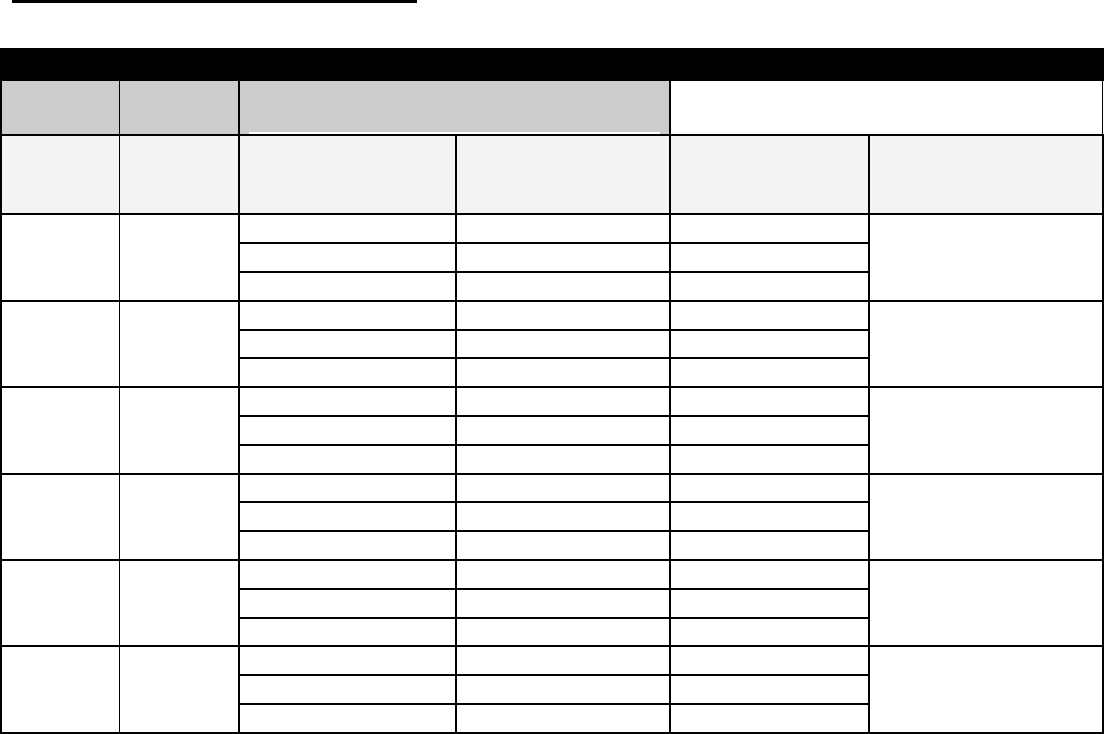

INSTALLATION OF SWG POWER VENTER (See Table 1)

Table 1

UNIT SIZING CHART

OIL GAS

MAXIMUM EQUIVALENT FEET OF VENT

PIPE

MAX*

OIL GPH

INPUT

MAX**

BTU/HR.

IMPUT

AT MAX BTU/HR

INPUT

AT 60% OF MAX

BTU/HR INPUT

VENTING WITH

VENT PIPE SIZE

MODEL

21 80 3”

50 100 4”

N/A 70,000

--- --- ---

SWG-3

--- 23 3”

35 100 4”

1.10 170,000

65 100 5”

SWGII-4HD

SWG-4s

16 44 4”

51 100 5”

1.85 290,000

95 100 6”

SWGII-5

SWG-5s

28 78 5’”

68 100 6”

2.65 416,000

100 100 7”

SWGII-6

SWG-6s

28 78 6”

61 100 7”

3.60 566,000

90 100 8”

SWG-7

26 72 7”

51 100 8”

4.75 740,000

70 100 9”

SWG-8

*Rating at 100 psi. Sizing based on appliance maximum input rate not actual firing rate. **Do not exceed maximum BTU/HR input rating or maximum oil

GPH input. For multiple venting system applications, add the input for each appliance. Category I gas-fired draft induced systems require an SWGII-4HD

or larger. Category III gas-fired draft induced systems require an SWGII-5 or larger.