1-19

Filtration Malfunction

The majority of ltration malfunctions arise from operator error. One of the most common errors is

placing the lter paper on the bottom of the lter pan rather than over the lter screen.

Inspect the lter paper to ensure that it is correctly sized and placed. Incorrectly sized or installed lter

paper will allow particles and sediment to pass through the lter pan and into the pump. When sediment

enters the pump, the gears can bind and cause the motor to overheat. If the motor overheats, the thermal

overload will trip to protect the motor from further damage. Reset the motor by pressing the red reset

button the end of the motor nearest the operator. Sediment cannot enter the pump when the correct

lter paper is used properly.

While you are checking the lter paper, verify that the O-rings on the lter pan and connectors are

present and in good condition. Missing or worn O-rings will allow the pump to suck air and decrease its

efciency.

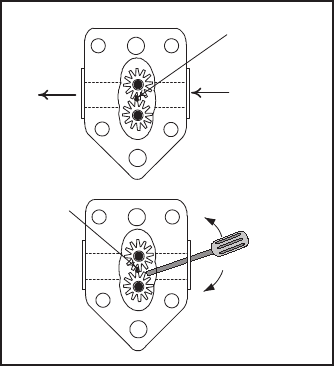

A pump seized by debris or hard shortening can usually be freed by manually moving the gears with a

screwdriver or other tool.

1. Disconnect power to the lter system.

2. Remove the input plumbing from the pump.

3. Use a screwdriver to manually turn the gears.

• Turn the pump gears backward to release a hard particle

and remove it.

• Turn the pump gears forward to push softer objects and

solid shortening through the pump and allow the gears to

move freely.

Incorrectly sized or installed paper will also allow food particles and sediment to pass through and clog

the suction tube on the bottom of the lter carriage. Particles large enough to block the suction tube may

indicate that the crumb tray is not being used during ltering.

Pan blockage can also occur if shortening remains in the pan and solidies. The heater strip on the

suction tube prevents solidication of residual shortening left in the tube. It will not melt or prevent

solidication of shortening in the pan. Remove blockages by forcing the item out with an auger or drain

snake. Compressed air or other pressurized gases should not be used to force out the blockage.

The Power Shower may need service for clogged openings, shortening solidied in the tubes, missing

clean-out plugs, and missing or worn O-rings. To correct these problems, clean the unit and replace

missing or worn plugs and O-rings.

Up for reverse

Sediment

Particle

Oil Flow

Down for forward

Sediment

Particle

Removing debris or shortening from

a seized pump.