2-7

2. Open the gas-supply valve to the fryer and check all piping, fittings, and gas connections for

leaks. A soap and water solution should be used for this purpose.

DANGER

All connections must be sealed with a joint compound suitable for the gas being

used and all connections must be tested with a solution of soapy water before

lighting any pilots.

Never use matches, candles, or any other ignition source to check for leaks. If gas

odors are detected, shut off the gas supply to the appliance at the main shut-off

valve and immediately contact the local gas company or an authorized service

agency for service.

3. Close the fryer drain valve and fill the frypot with water and boil-out solution to the bottom OIL-

LEVEL line at the rear of the frypot. Light the fryer and perform the boil-out procedures that are

described in the "Lighting Instructions" and "Boiling Out the Frypot" topics found in Chapter 3

of this manual.

DANGER

"Dry-firing" your unit will cause damage to the frypot and can cause a fire. Always

ensure that melted shortening, cooking oil, or water is in the frypot before firing your

unit.

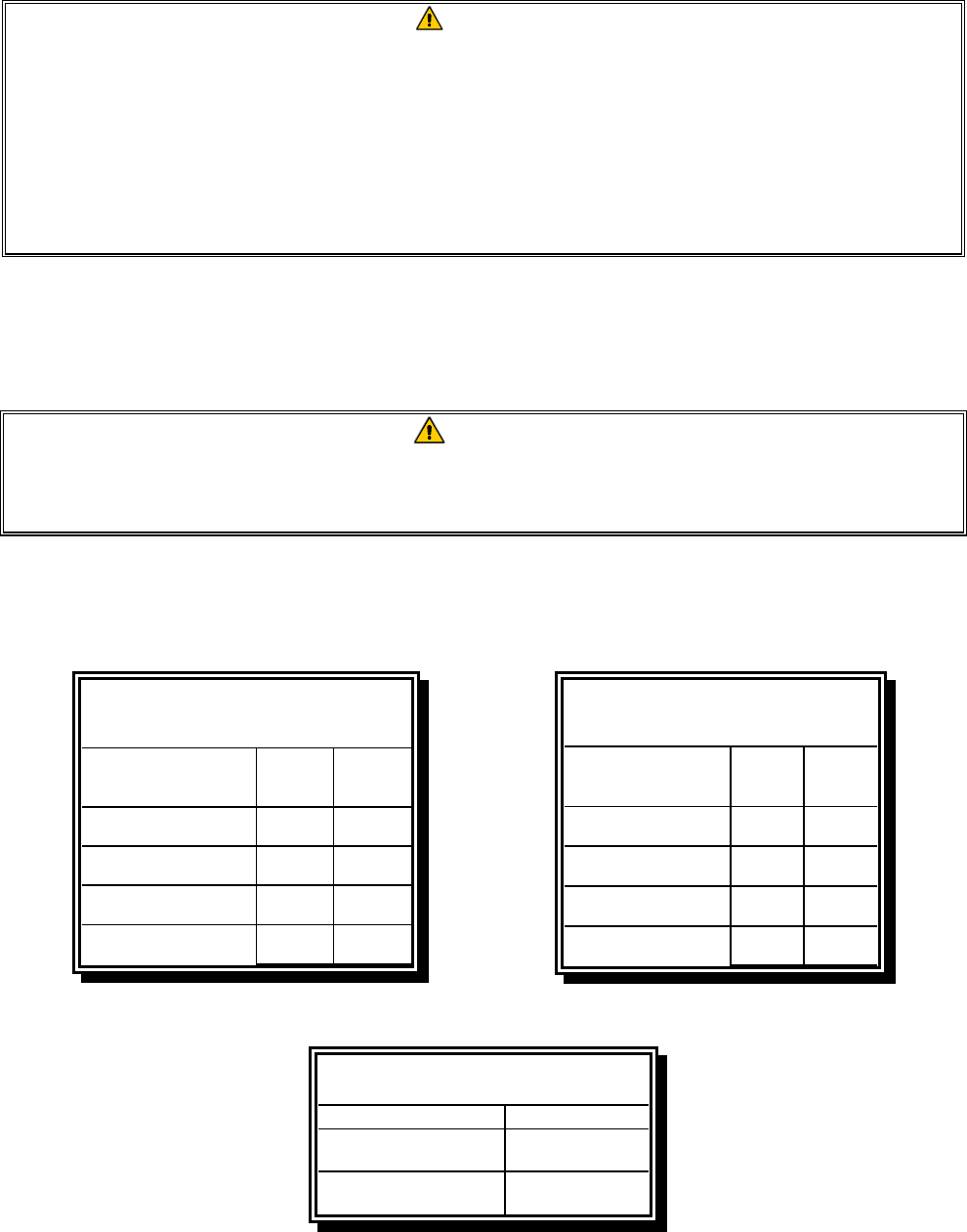

4. The burner manifold pressure should be checked at this time by the local gas company or an

authorized service agent. The tables below indicate the proper burner manifold pressures:

Gas

Model 35

Pressure

(mbar)

Model 45

Pressure

(mbar)

Natural Gas Lacq

(G20) under 20 mbar

97,5

Natural Gas Gronique

(G25) under 25 mbar

13,5 10

Natural Gas Gronique

(G20) under 20 mbar

13,5 10

Propane

(G31) under 37 or 50 mbar

22,5 20,6

Table 5: CE Standar

d

Burner Manifold Gas Pressures

(

Other than Bel

g

ium

)

Gas

Model 35

Pressure

(mbar)

Model 45

Pressure

(mbar)

Natural Gas Lacq

(G20) under 20 mbar

97,5

Natural Gas Gronique

(G25) under 25 mbar

97

Natural Gas Gronique

(G20) under 20 mbar

910

Propane

(G31) under 37 or 50 mbar

22,5 20,6

Table 6: CE Standar

d

Burner Manifold Gas Pressures

(

Bel

g

ium

)

Gas Pressure

Natural

3" W.C.

0.73 kPa

LP

8.25" W.C.

2.5 kPa

Table 7: Non-CE Standard

Burner Manifold Gas Pressures