DECATHLON SERIES GAS FRYERS (CE)

CHAPTER 3: INSTALLATION

3-4

3.5 Gas Connections

DANGER

Before connecting new pipe to this appliance the pipe must be blown out thoroughly

to remove all foreign material. Foreign material in the burner and gas controls will

cause improper and dangerous operation.

A. The gas supply (service) line must be the same size or greater than the fryer inlet line. This fryer

is equipped with a 22 mm (3/4") male inlet. The gas supply line must be sized to accommodate

all the gas-fired equipment that may be connected to that gas supply. Consult your contractor,

gas company, supplier, or other knowledgeable authorities.

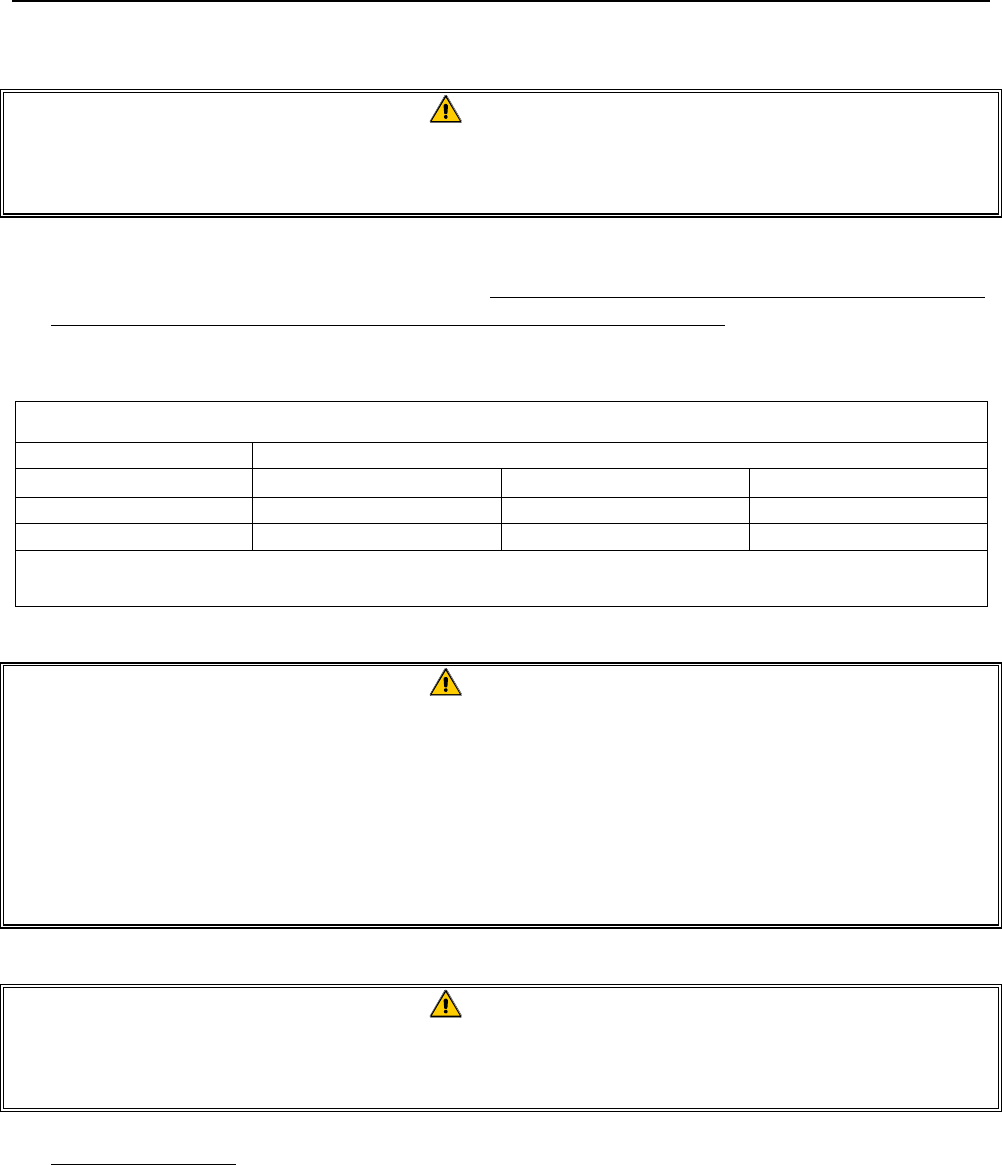

Recommended Gas Supply Line Sizes

Gas Types Number of Fryers

1 2 to 3 4 or more (*)

G20 and G25 22 mm (3/4") 28 mm (1") 35 mm (1-1/4")

G31 15 mm (1/2") 22 mm (3/4") 28 mm (1")

(*) When exceeding 6 meters (18 feet) for a configuration of more than four fryers, it is necessary

to provide a 35 mm (1-1/4") rigid gas connection.

DANGER

All connections must be sealed with a joint compound suitable for the gas being

used and all connections must be tested with a solution of soapy water before

lighting any pilots.

Never use matches, candles, or any other ignition source to check for leaks. If gas

odors are detected, shut off the gas supply to the appliance at the main shut-off

valve and immediately contact the local gas company or an authorized service

agency for service.

DANGER

"Dry-firing" your unit will cause damage to the frypot and can cause a fire. Always

ensure that melted shortening, cooking oil or water is in the frypot before firing the

unit.

B. Rigid Connections: Check any installer-supplied intake pipe(s) visually and clean threading

chips, or any other foreign matter before installing into a service line. If the intake pipes are not

clear of all foreign matter, the orifices will clog when gas pressure is applied. Seal pipe joints

with a sealant resistive to G31 gas. When using thread compound on gas piping, use very small

amounts and only on male threads. Use a pipe thread compound that is not affected by the

chemical action of G31 gases. DO NOT apply thread compound to the first two pipe threads—

doing so will cause clogging of the burner orifices and control valve.