25

Model ERV Energy Recovery Unit

Vibration

Excessive vibration may be experienced during initial

start-up. Left unchecked, excessive vibration can

cause a multitude of problems, including structural

and/or component failure. The most common sources

of vibration are listed.

Many of these conditions can be discovered by

careful observation.

Refer to the

Troubleshooting

section of this manual

for corrective actions.

If observation cannot

locate the source of

vibration, a qualified

technician using

vibration analysis

equipment should be consulted. If the problem is

wheel unbalance, in-place balancing can be done.

Generally, fan vibration and noise is transmitted

to other parts of the building by the ductwork. To

eliminate this undesirable effect, the use of heavy

canvas connectors is recommended.

Wheel Unbalance

Drive Pulley Misalignment

Incorrect Belt Tension

Bearing Misalignment

Mechanical Looseness

Faulty Belts

Drive Component Unbalance

Poor Inlet/Outlet Conditions

Foundation Stiffness

Drive Belt

Inspect the drive belt. Make sure the belt rides

smoothly through the pulley and over the wheel rim.

Air Seals

Check that the air seals located around the outside of

the wheel and across the center (both sides of wheel)

are secure and in good condition. Air seal clearance

is determined by placing a sheet of paper, to act as a

feeler gauge, against the wheel face. To access seals,

enter the unit for the ERV-581 and 582, or pull out the

cassette for the ERV-251, 361, 521, and 522, following

the instructions in the Energy Recovery Wheel

Maintenance section. To adjust the air seals, loosen

all eight seal retaining screws. These screws are

located on the bearing support that spans the length

of the cassette through the wheel center. Tighten the

screws so the air seals tug slightly on the sheet of

paper.

Replace cassette into unit, plug in wheel drive,

replace access door and apply power. Observe by

opening door slightly (remove filters if necessary to

view wheel) the wheel should rotate freely at about

50-60 RPM.

Energy Recovery Wheel

The ERV models contain a

total energy recovery wheel.

The wheels are inspected

for proper mechanical

operation at the factory.

However, during shipping

and handling, shifting

can occur that may affect

wheel operation. The wheel

is accessible through

the access door marked

“Energy Wheel Cassette

Access”. For the ERV-

251, 361, 521, and 522,

the wheel cassette(s)

slide out. Due to the size

and weight of the ERV-

581 and 582 wheels, they

remain stationary and all

maintenance is performed

in place. There is room inside the unit to perform

energy recovery wheel servicing.

Turn the

energy

recovery

wheels by

hand to verify

free operation.

The wheel

should rotate

smoothly and

should not

wobble.

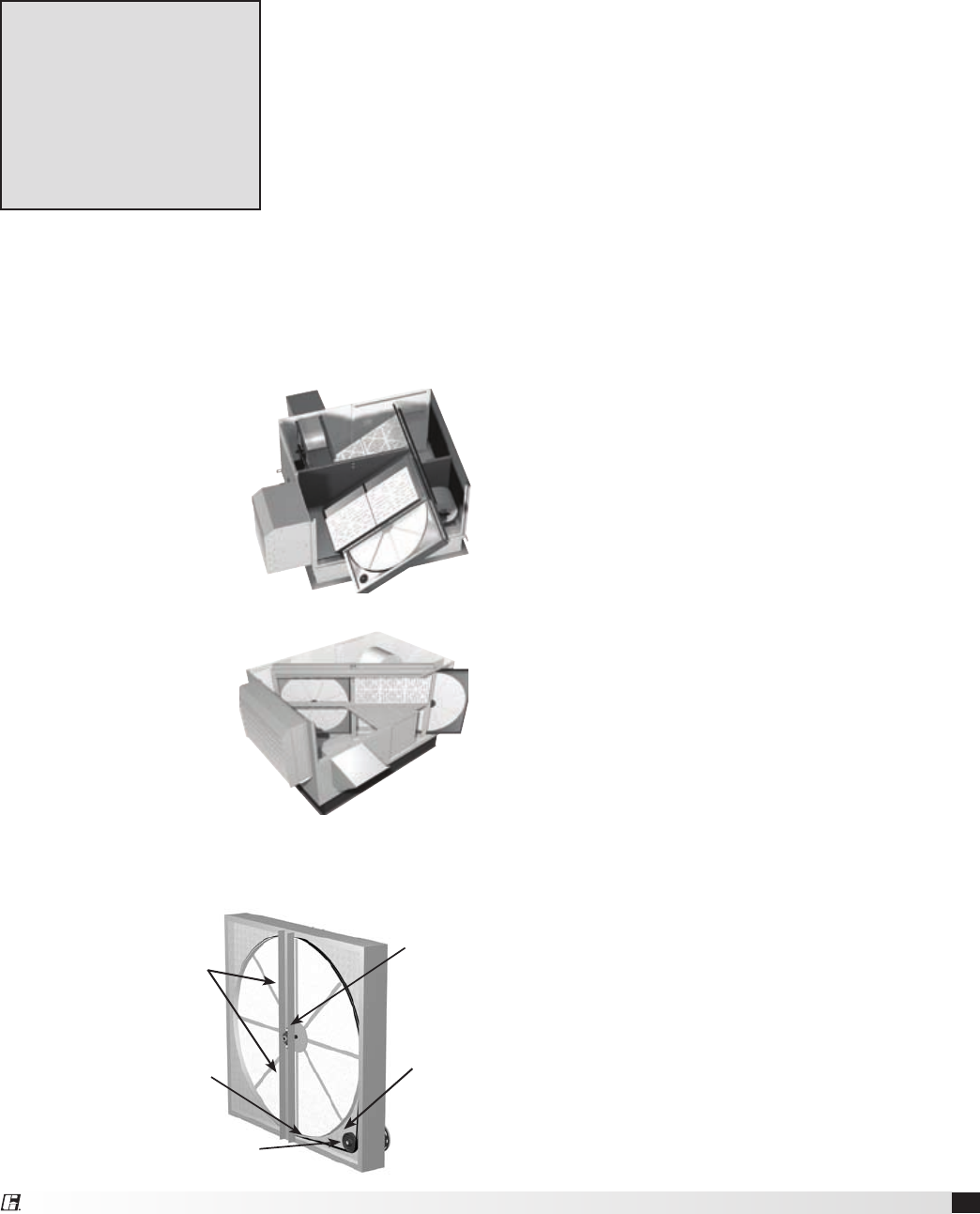

Inside layout of ERV-361

Inside layout of ERV-522

Drive Belt

Adjustable

Air Seals

Label

showing

cassette

serial #

and date

code

Bearing

Support

Drive Pulley