Henny Penny Model 580

5-20. SOLENOID VALVE 7. With the bonnet assembly and core-disc assembly

Replacement (Continued) removed, disconnect the two nut fittings. One connects

the solenoid valve to the dead weight system; the other is

attached to the condensation tank.

8. Remove the elbows from the solenoid valve.

9. Remove the two adapter screws which attach the pipe

adapter to the solenoid valve body.

10. Remove the disc spring, guide, and Teflon seat.

11. Clean the valve body.

12. Wet “O” ring around seat with water and insert “O” ring

assembly (flat side first) in valve through “IN” side of

body. Use an eraser end of pencil and press in the Teflon

seal until it snaps into place. BE CAREFUL NOT TO

MAR OR NICK THE SEAT.

NOTE

The smallest nick can cause a pressure leak. Replace all

“O” ring seals that are in the parts kit and reassemble

valve.

13. If the complete valve is being replaced, follow steps 1, 2,

3, 4, 5, 7, and 8, in this section.

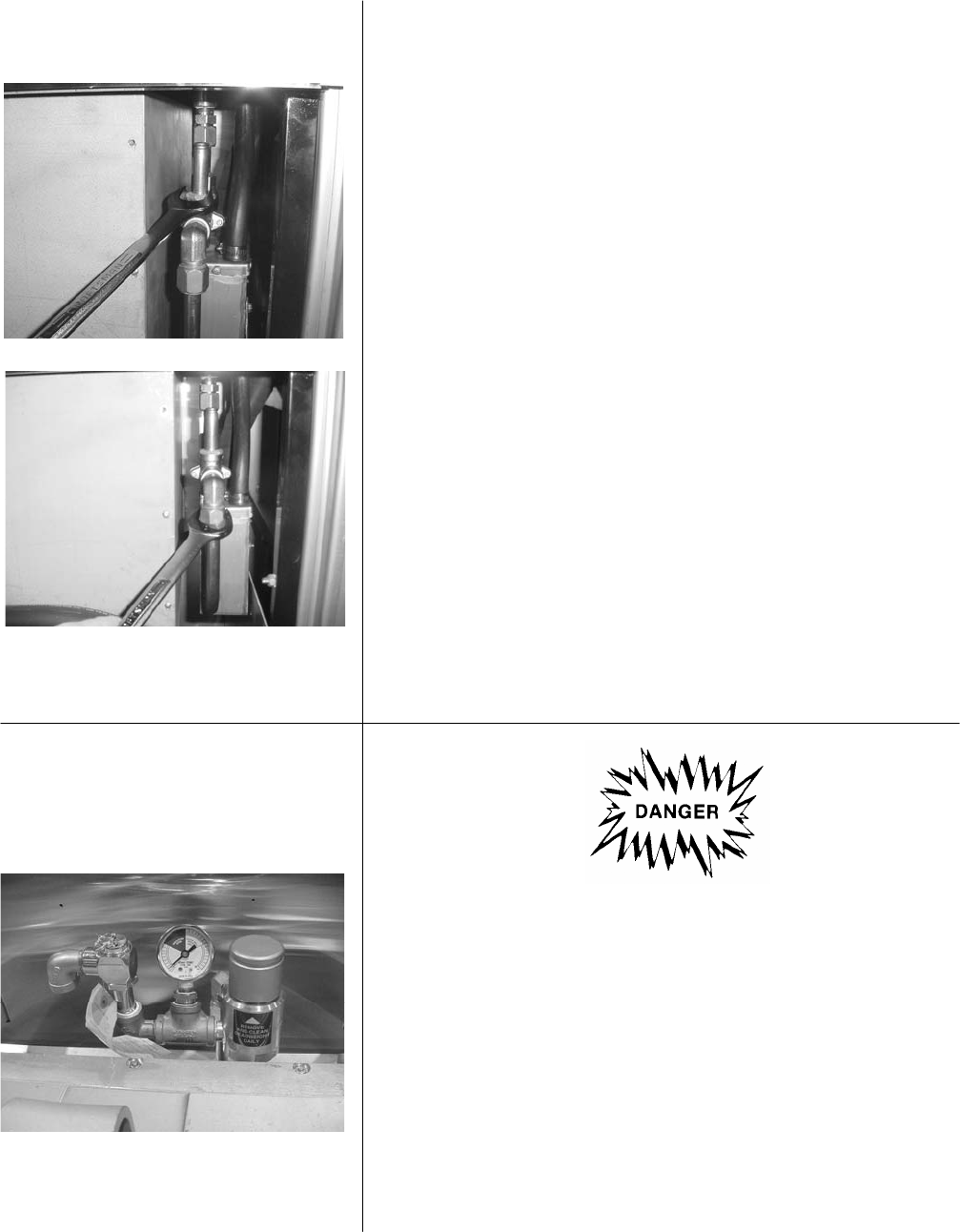

5-21. OPERATING CONTROL

VALVE

DO NOT ATTEMPT TO REMOVE THE VALVE CAP

WHILE THE FRYER IS OPERATING, or severe burns

or other injuries could result.

The operating valves are located at the back of the unit. The

valve left of the pressure gauge is a 14 ½ lb. safety relief valve,

and to the right of the pressure gauge, the operating valve.

Valves are working properly, when “OPERATING ZONE”

indicates on the gauge by the pointer. The gauge pointer

should not normally exceed the operating zone. If the pressure

builds to 14 ½ lbs., the safety relief valve opens and releases

pressure from the frypot.

5-20 1200