– 12 –

ELECTRICAL CONNECTIONS

WARNING: ELECTRICAL AND GROUNDING CONNECTIONS MUST COMPLY WITH THE APPLICABLE

PORTIONS OF THE NATIONAL ELECTRICAL CODE AND/OR OTHER LOCAL ELECTRICAL CODES.

WARNING: DISCONNECT THE ELECTRICAL POWER TO THE MACHINE (BOTH DISHWASHER AND

BOOSTER IF APPLICABLE) AND FOLLOW LOCKOUT / TAGOUT PROCEDURES.

Refer to the wiring diagram attached inside the front trim panel and to the machine data plate for service

size requirements when connecting the dishwasher. Also, refer to Electrical Data, page 12.

To access the controls area, remove the right side panel, remove the front panel and open the control

panel door. The dishwasher electrical service connection can be made through the 1

3

/32" diameter hole

for

3

/4 inch trade size conduit located on the right side at the rear of the machine. By removing a

knockout, this hole can be enlarged to 1

3

/8" diameter for 1 inch trade size conduit, if required.

A fused disconnect switch or circuit breaker (not supplied) must be installed in the electrical service

line(s) supplying this dishwasher and should meet the requirements of your local electrical code.

Dishwasher Without Electric Booster

For single-phase machines, power supply connections are made to terminal blocks. For three-phase

machines connections are made to contactor lugs. The machine must be grounded according to

electrical code(s); a grounding lug is provided in the controls area. Electrical connections for machines

with gas tank heat are made to contactor 1CON in the controls area.

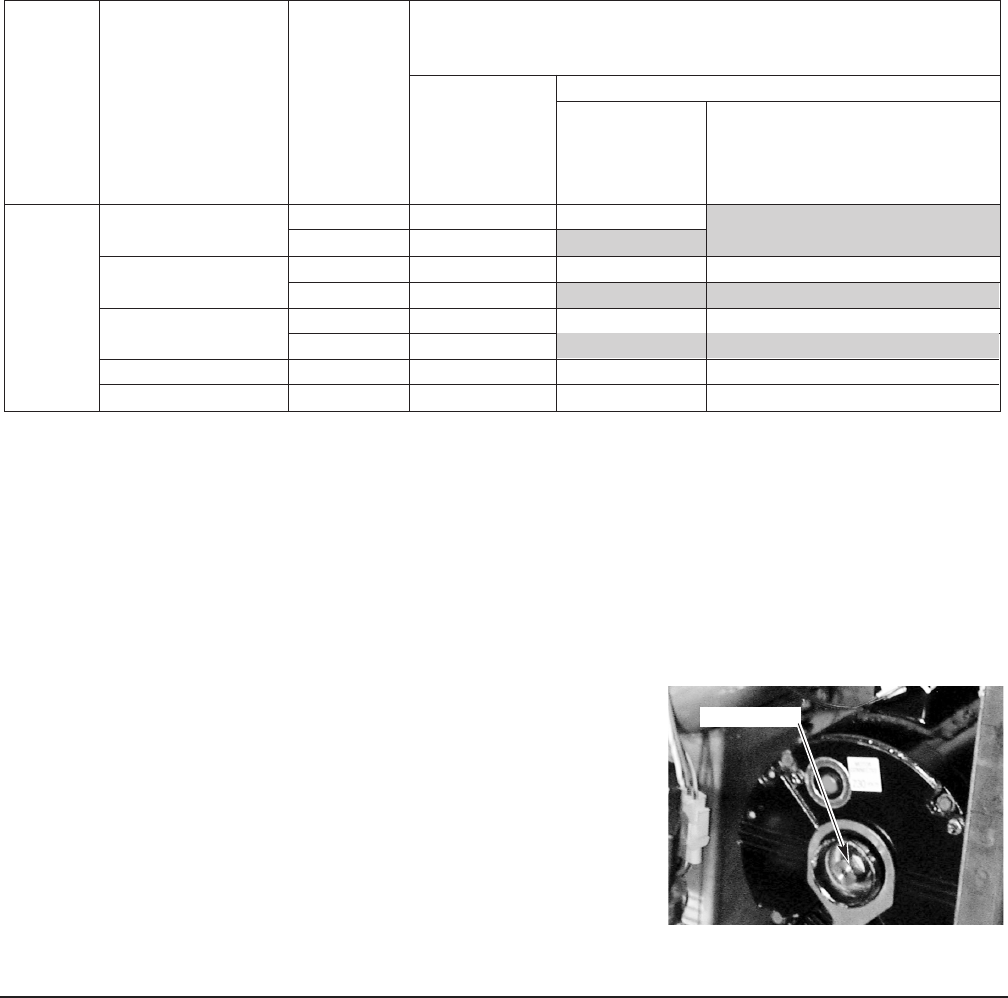

Check Rotation (Three-Phase Machines Only)

Three-phase motors must rotate in the direction of the arrow on

the pump housing. In order to check rotation, remove the bearing

cap to observe the motor shaft (Fig. 15). Close the machine doors

and press the power switch to ON. When the machine is completely

filled, open and close machine doors to verify that the motor shaft

rotates in the clockwise direction.

If the rotation is incorrect, DISCONNECT ELECTRICAL POWER

SUPPLY and interchange any two of the incoming power supply

leads. Reconnect the power supply and verify correct rotation.

Replace the motor bearing cap.

Fig. 15

MOTOR SHAFT

ELECTRICAL DATA

Minimum Circuit Ampacity

Maximum Protective Device

AMPS

Models Volts / Hz / Ph Tank Heat Optional 13 KW Electric Booster

Dishwasher 13KW Optional Single Point

ONLY Booster Electrical Connection

ONLY 3 Phase Only

Dishwasher and Booster

208 - 240 / 60 / 1

Electric 50 70

Gas 20

AM15

208 - 240 / 60 / 3

Electric 30 40 70

AM15F Gas 15

AM15T

480 / 60 / 3

Electric 15 20 35

Gas 15

200 - 240 / 50 / 3 Electric 30 40 70

380 - 415 / 50 / 3 Electric 15 30 45

Compiled in accordance with the national electrical code, NFPA 70 (latest edition).