– 16 –

TROUBLESHOOTING

Symptoms that persist after possible causes have been checked may require service.

SYMPTOMS POSSIBLE CAUSES

No Machine Operation 1. Machine

POWER

switch in the

OFF

position.

2. Blown fuse or tripped circuit breaker at power supply.

3.

DELIME/NORMAL

switch in the

DELIME

position and machine in the middle of

a cycle.

Continuous Machine 1.

DELIME/NORMAL

switch in

DELIME

position.

Operation 2. Problem with timer. Contact your local Hobart Service Office.

Dishes Not Clean 1. Pump intake strainer clogged causing inadequate water supply to pump.

2. Obstruction in wash arm nozzles or bearings preventing arms from turning.

Refer to C

LEANING THE DISHWASHER, page 12.

3. Wash arms improperly assembled. Make sure end caps are assembled and the

knurled disks on the wash / rinse arm hubs are secure.

4. Inadequate fill due to low supply water pressure and / or improper cycle timer

adjustment.

5. Water temperature too low (140°F recommended, 120°F minimum).

6. Improper water hardness (4 – 6 grains/gallon is recommended).

7. Excessive lime deposits throughout wash/rinse system.

8. Dirty line strainer (see Fig. 6) causing reduced water flow. Turn off water supply,

remove strainer cap, withdraw and clean screen, and reassemble.

9. Incorrect type or concentration of detergent.

10. Check to make sure chemical supply hoses are in the their proper container:

Red in detergent, blue in rinse aid, white in sanitizer. Also, check the standpipes

to make sure they extend to the bottom of the container.

11. Wash tube disconnected from manifold or O-ring leaking, resulting in low water

pressure to upper arm.

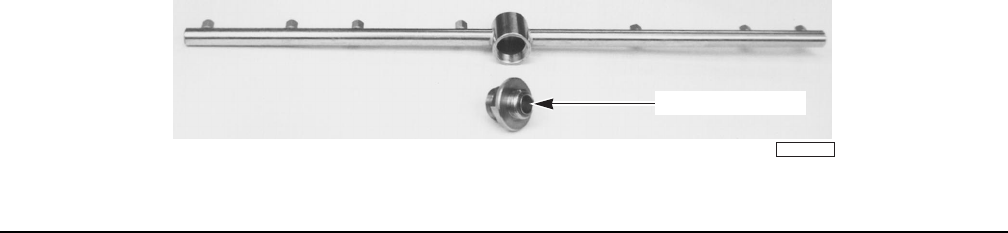

12. Wash arm bearings (Fig. 22) damaged or excessively worn, preventing free

rotation of the wash arm. To change the wash arm bearing assembly, unscrew

bearing assembly from wash/rinse arm and replace with a new bearing assembly.

13. Check for empty chemical containers.

Spotting of Silverware, 1. Improperly loaded racks.

Glasses, or Dishes 2. Water temperature too low (140°F recommended, 120°F minimum).

3. Improper water hardness (4 – 6 grains/gallon is recommended).

4. Improper concentration of detergent, rinse aid, and/or sanitizer.

Fig. 22

FORM 18580 REV. A (8-96) PRINTED IN U.S.A.

PL-40935-1

WASH ARM BEARING