14 www.honeywell.com

PW-6000 Installation

Setting Up the PW-6000 Hardware

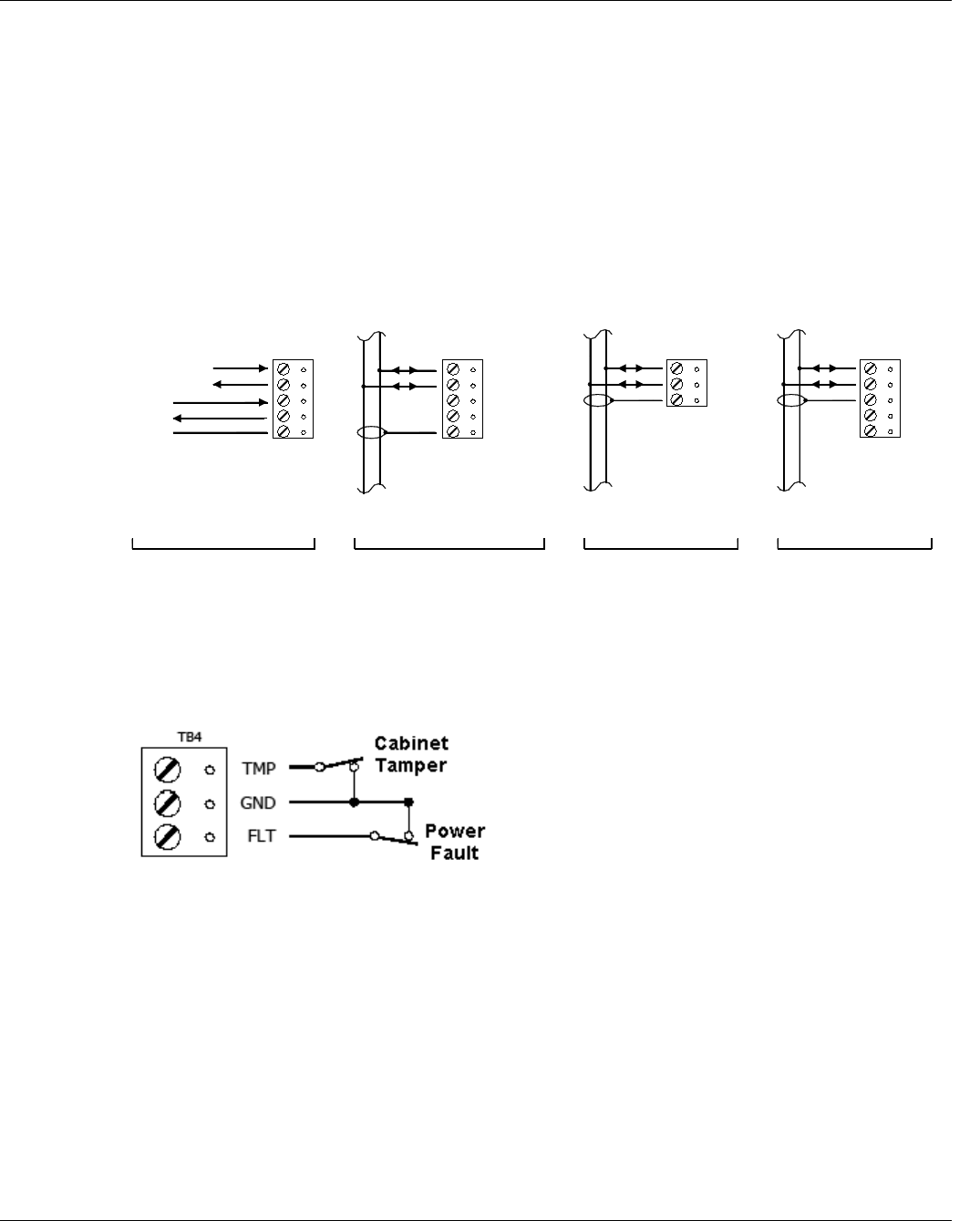

3.6 Communications Wiring

The PW-6000 processor communicates to the host via on-board Ethernet 10Base-T/100Base-TX port

or on port 1. Port 1 may be configured as RS-232, two-wire RS-485 or optional Lantronix Ethernet

10Base-T/ 100Base-TX CoBox-Micro interface. The RS-232 interface is for direct one to one

connection to a host computer, or a modem.

Ports 2 and 3 use the two-wire RS-485 interface only. The interface allows multi-drop communication

on a single bus of up to 4,000 feet (1,200 meters). Use shielded twisted pair (minimum 24 AWG) with

120-ohm impedance. Install termination jumpers only at the end-of-line unit.

Figure 3: PW-6000 Port Wiring

3.7 Cabinet Tamper and Power Failure Input Wiring

Figure 4: PW-6000 TMP and FLT Terminals

Inputs TMP and FLT are used for monitoring cabinet tamper and power failure with normally closed

contacts. These two inputs are for contact closure monitoring only; do not use end-of-line (EOL)

resistor(s). If these inputs are not used, install a short piece of wire at the input to indicate a safe

condition.

3.8 Memory and Real Time Clock Backup Battery

The event log buffer and the real time clock are backed up by a 3V lithium battery. This BR2325,

BR2330, or CR2330 battery should be replaced annually.

PORT 1 CONFIGURED

as 2-WIRE RS-485

TXD/TR+

RXD/TR-

RTS

CTS

GND

PORT 1 CONFIGURED

as RS-232

GND

TXD/TR+

RXD/TR-

RTS

CTS

PORT 2

TR-

TR+

GND

2-WIRE RS-485

PORT 3

2-WIRE RS-485

TB2 TB1

TR-

GND

TR+

GND

+12V

TB3TB3