25

0713

‘

2. Close Beverage Control Panel Assembly water

inlet supply line shutoff valve.

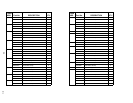

3. Loosen screen retainer, then pull screen retainer

and strainer screen from water pump. (see

Figure 12).

4. Pull strainer screen from screen retainer. Clean

any sediment from screen retainer and pump

screen retainer port.

WATER PUMP

O–RING

(P/N 315349–000)

SCREEN RETAINER

WATER

STRAINER SCREEN

(P/N 315348–000)

FIGURE 12. WATER STRAINER SCREEN

5. Inspect strainer screen for holes, restrictions,

corrosion, and other damage. Discard damaged

strainer screen.

6. Check O–Ring on screen retainer. Replace worn

or damaged O–Ring (P/N 315349–000).

NOTE: A strainer screen should always be used,

otherwise particles could foul liquid check valve.

7. Install good or new strainer screen (P/N

315348–000) in screen retainer, then screw

retainer into water pump and tighten securely.

8. Service liquid check valve (refer to next

paragraph, Servicing Liquid Check Valve).

Servicing Liquid Check Valve

1. Service water pump water strainer screen as

instructed in previous paragraph, Servicing

Water In let Strainer Screen; before servicing

liquid check valve.

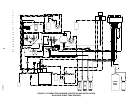

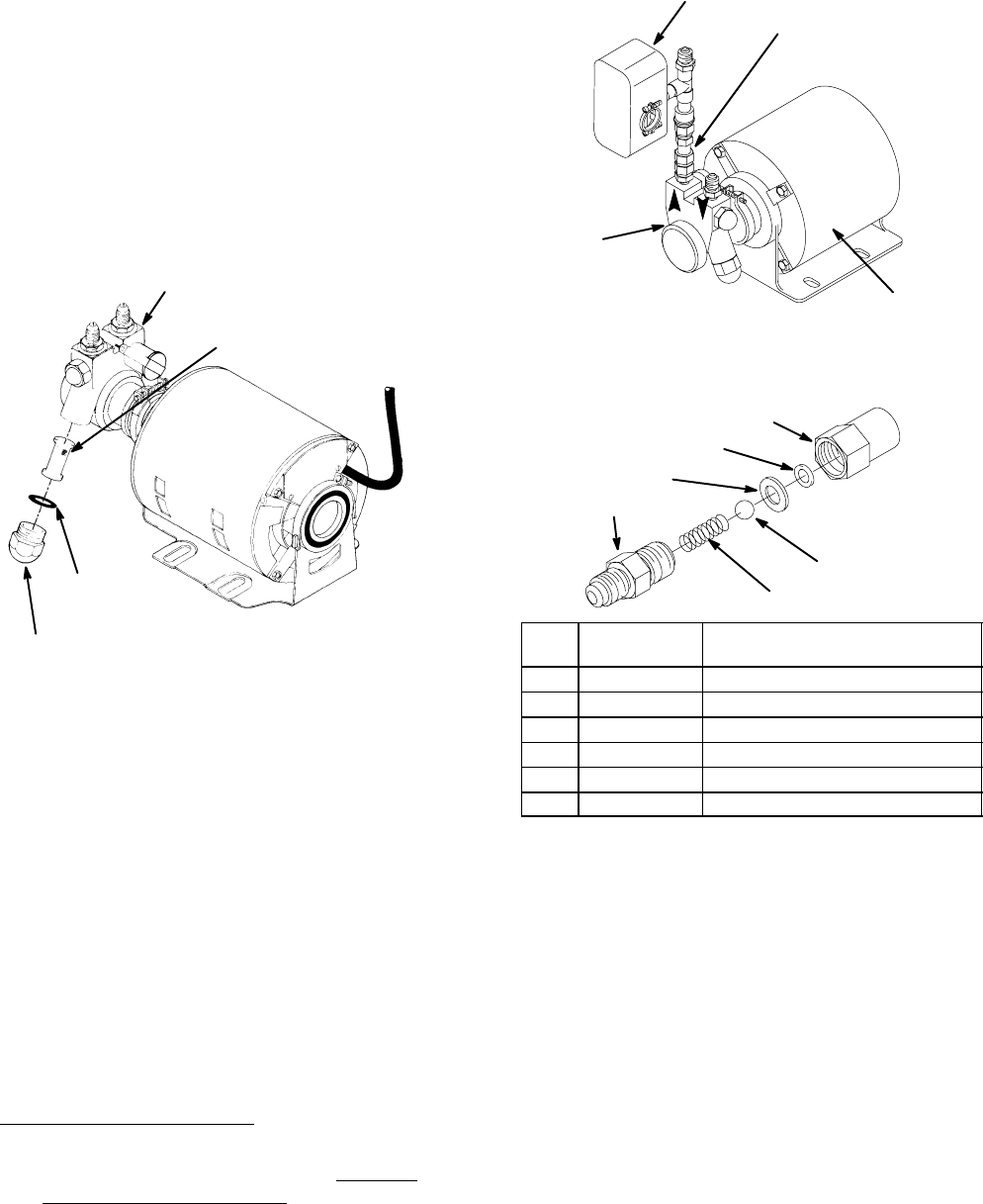

2. Disconnect pressure switch (see Figure 13) from

liquid check valve assembly outlet, then remove

check valve from water pump outlet. Retain

white tapered gasket inside inlet (female) end of

check valve.

PRESSURE

SWITCH

LIQUID CHECK

VALVE

WATER

PUMP

MOTOR

FIGURE 13. WATER PUMP AND MOTOR

1

2

3

4

5

6

Index

No.

Part

No.

Name

1 317963 Housing

2 312415 Flat Washer, Stainless Steel

3 *312418 Ba;; Seat (quad ring)

4 312419 Ball

5 312196 Spring

6 317965 Retainer

*Install new ball seat at each servicing.

FIGURE 14. LIQUID CHECK VALVE ASSEMBLY

3. Disassemble each check valve as shown in

Figure 14

4. Wipe each part with clean lint–free cloth. Inspect

each part, especially ball for burrs, nicks,

corrosion, deterioration, and other damage.

Discard ball seat and any damaged or suspicious

parts and replace with new parts when

reassembled.

5. Reassemble check valve as shown in Figure 14.

ALWAYS INSTALL NEW BALL SEAT

(QUADDING) P/N 312418–000.

6. Make sure white tapered gasket is in place

inside female end of check valve assembly, then

install check valve assembly on fitting in water

pump outlet port.

7. Connect pressure switch to check valve

assembly outlet.