0713

28

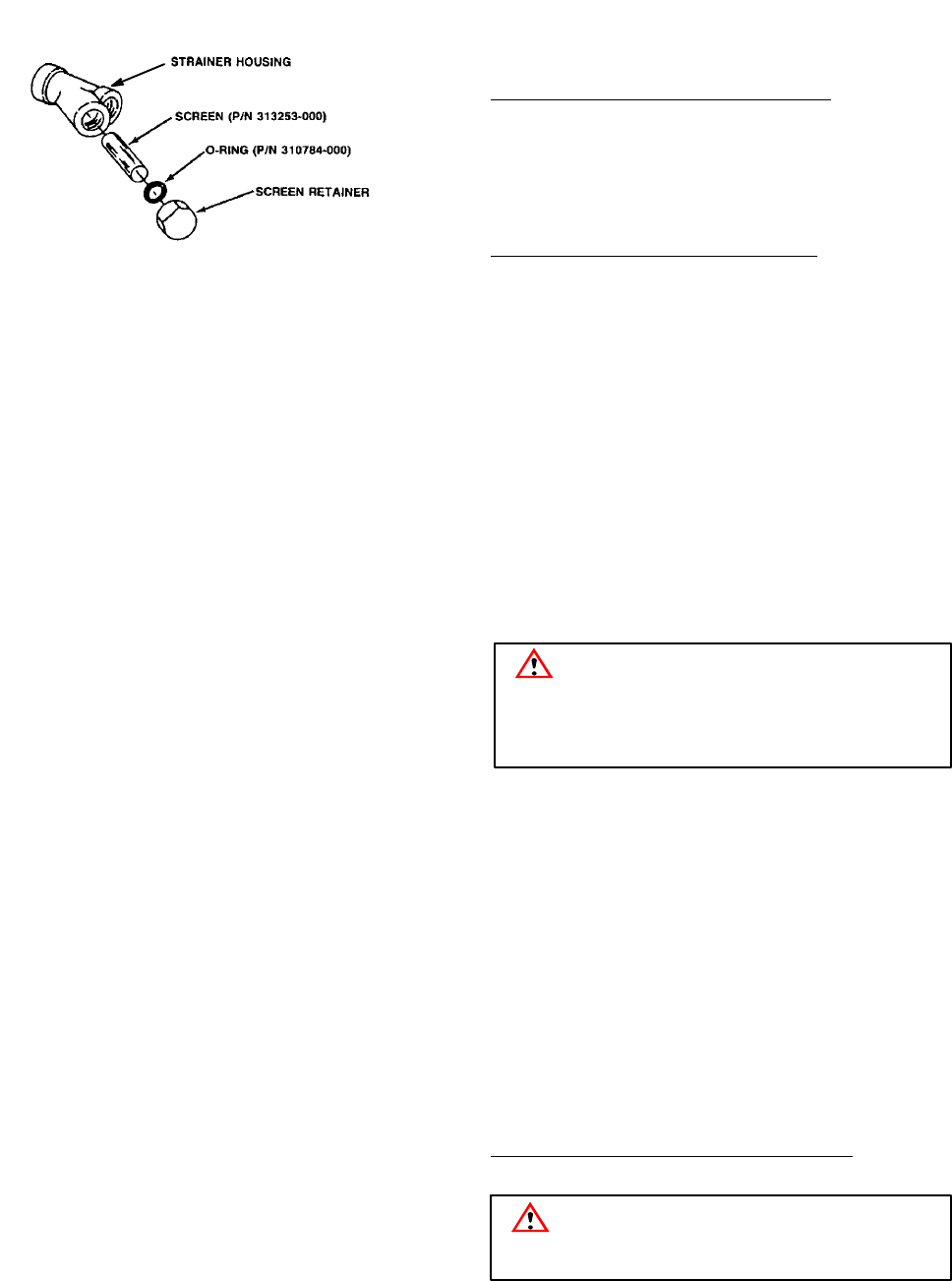

FIGURE 16. SYRUP LINE STRAIANER

1. Using chlor–tergent (Oakite Products, Inc.) or

equivalent sanitizer and LUKEWARM water, mix

2–1/2 gallons (9.46 liters) of sanitizing solution in

a bucket.

2. Disconnect syrup out quick disconnects,

containing the syrup strainers, from all syrup

tanks.

3. Activate all dispensing valves on Dispensers to

relieve pressure from all syrup systems.

4. Loosen syrup strainer screen (see Figure 3–5)

retainer, then pull syrup strainer and screen from

syrup strainer housing.

5. Pull screen from screen retainer. Inspect screen

for holes, restrictions, corrosion, and any other

damage. Discard damaged screen and replace

with a new one.

6. Place quick disconnect and syrup strainer

housing in bucket containing sanitizing solution.

Thoroughly wash quick disconnect and syrup

strainer housing, screen retainer, and screen in

sanitizing solution.

7. Thoroughly rinse quick disconnect and syrup

strainer housing, screen retainer and screen with

potable water.

8. Install screen in screen retainer, then screw

screen retainer into water strainer housing.

Tighten retainer only finger tight.

9. Repeat steps 4) through 8) to clean and sanitize

remaining syrup strainers.

10. Sanitize all syrup systems as instructed.

11. Connect syrup out quick disconnects to all syrup

tanks.

WATER FILTERS REPLACEMENT

Refer to Water Filtration System manual for water

filters replacement instructions.

SANITIZING SYRUP SYSTEMS

The syrup systems should be sanitized every

90–days using Chlor–Tergent (Oakite Products, Inc.)

or equivalent sanitizer. Refer to manual provided with

the Post–Mix Dispenser for sanitizing instructions.

REPLENISHING CO

2

SUPPLY

NOTE: When indicator on CO

2

cylinder regulator

assembly 1800–PSI (124.1 Bars) gauge is in

shaded (‘‘Change CO

2

Cylinder’’) portion of dial,

CO

2

cylinder is almost empty and should be

changed.

1. Fully close (clockwise) CO

2

cylinder valve.

2. Slowly loosen CO

2

regulator assembly coupling

nut allowing CO

2

pressure to escape, then

remove regulator assembly from empty CO

2

cylinder.

3. Unfasten safety chain and remove empty CO

2

cylinder.

WARNING: To avoid personal injury

and/or property damage, always secure

CO

2

cylinder with safety chain to prevent if from

falling over. Should the valve become acciden-

tally damaged or broken off, CO

2

cylinder can

cause serious personal injury.

4. Position CO

2

cylinder and secure with safety

chain.

5. Make sure gasket is in place inside CO

2

regulator coupling nut, then install regulator on

CO

2

cylinder.

6. Open (counterclockwise) CO

2

cylinder valve

slightly to allow lines to slowly fill with gas, then

open valve fully to back–seat valve.

(Back–seating valve prevents leakage around

valve shaft).

7. Check CO

2

connections for leaks. Tighten loose

connections.

REPLENISHING SYRUP SUPPLY

WARNING: To avoid personal injury or

property damage, do not attempt to re-

move syrup tank cover until CO

2

pressure has

been released from tank.