7

0713

A. Locate two full CO

2

cylinders in upright

positions next to the CO

2

mounting

bracket. Fasten CO

2

cylinders with safety

chain.

B. Connect two CO

2

lines from Beverage

Control Panel Assembly two primary CO

2

regulators to the CO

2

cylinders.

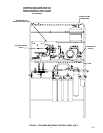

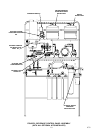

7. Installation employing the Optional Water

PressureBooster System Kit (see applicable

Figure 3, 4, 5, or 6)

Note service valve on bottom of the Water Pressure

Booster System Water Tank. The water tank must be

pressurized with 40 5–PSI (2.76 .34 Bars) of

commercially dry air, CO

2

, or nitrogen gas through

the water tank service valve before putting system

into operation.

8. Water Surge Tank (see applicable Figure 3, 4,

5,, or 6)

Note service valve on bottom of the water surge

tank. The water surge tank must be pressurized with

12 2–PSI (.83 .14 Bars) of commercially dry air,

CO

2

, or nitrogen gas through the water tank service

valve before putting system into operation.

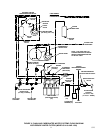

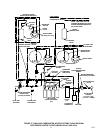

9. System Connected to Bulk CO

2

Supply (see

Figure 7)

A. Open shutoff valve on bulk CO

2

tank.

B. Adjust CO

2

regulator on bulk CO

2

tank to

105–PSI (7.24 Bars). Pull up on

carbonators tanks relief valves for

approximately two seconds to bleed air

from tanks.

C. Adjust sugar–base syrup tanks CO

2

regulator with 100–PSI (6.9 Bars) gauge on

secondary CO

2

regulator assembly to

60–PSI (4.14 Bars).

D. Adjust diet syrup tank CO

2

regulator with

30–PSI (2.07 Bars) gauge on secondary

CO

2

regulator Assembly to 12–PSI (.83

Bars).

10. System connected to two fifty pound CO

2

cylinders (see Figure 7).

A. Open CO

2

cylinders valves slightly to allow

lines to slowly fill with gas, then open

valves fully to back seat valve.

Back–seating valve prevents leakage

around valve shaft.

B. Adjust two Primary CO

2

regulators to

105–PSI (7.24 Bars). Pull up on

carbonator(s) tank(s) relief valve(s) for

approximately two seconds to bleed air

from tanks.

C. Adjust secondary CO

2

regulator assembly

CO

2

regulator with 100–PSI (6.9 Bars)

gauge for sugar–base syrup tanks to

60–PSI (4.14 Bars).

D. Adjust diet syrup tank CO

2

regulator with

30–PSI (2.07 Bars) gauge on secondary

CO

2

regulator assembly to 12–PSI (.83

Bars).

11. The Post–Mix Dispenser(s) and entire syrup

systems should be sanitized as instructed in

manual(s) provided with Dispenser(s) before

syrup is connected into the systems.

IMPORTANT: Even though sanitizing procedure

has been performed on syrup systems during

initial installation a temporary new tubing plastic

off–taste of dispensed product may occur. If this

off–taste should occur, prepare a solution of

citric acid in proportion as instructed on the

citric acid packaging. Pump citric acid solution

through the syrup systems and all carbonated

and plain water tubes installed as part of the

system. Thoroughly flush syrup systems and all

carbonated and plain water tubes with plain

water to make sure all citric acid has been

removed.

12. Open all plain water shutoff valves on Beverage

Control Panel Assembly.

13. Check entire system for syrup, CO

2

gas, and

plain and carbonated water leaks. Repair if

leaks are evident.

14. Plug carbonator(s) and Water Pressure Booster

system (if applicable) power cords into electrical

outlets.

15. If Optional Air Compressor Kit is being used and

it is desired to operate with compressed air

rather than CO

2

gas pressure.

A. Plug air compressor power cord into

electrical outlet.

B. Place CO

2

/air switchover valve (see Figure

7) in air position.

16. Refer to manual(s) provided with the

Dispenser(s) to put Dispenser(s) into operation.

Operate all dispensing valves to bleed all air

from plain and carbonated water systems.

17. Standard Installation Connected to Bulk Syrup

Tanks (see Figure 7)