4

0713

INSTALLATION

This manual is intended to assist the installer and

service personnel in the installation, operation, and

maintenance procedures to be performed on the

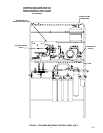

Beverage Control Panel Assembly (see Figure 1 and

applicable Figure 3, 4, 5, or 6).

The Beverage Control Panel Assembly is designed

to filter, pressure regulator, and distribute plain and

carbonated water, CO

2

gas, and syrup to the

Post–Mix Beverage Dispenser or dispensers and

various other equipment connected to the system.

NOTE: The Beverage Control Panel Assembly is

manufactured in America and has American

sizes on the hardware. All metric conversion are

approximate and vary in size.

NOTE: The Beverage Control Panel Assembly

was thoroughly inspected before leaving the

factory and the carrier has accepted and signed

for it. Any damage or irregularities should be

noted at the time of delivery (or not later than 15

days from date of deliver) and immediately

reported to the delivering carrier. Request a

written inspection report from Claims Inspector

to substantiate any necessary claim. File claim

with the delivering carrier, not with IMI Cornelius

Inc.

INSTALLING POST–MIX DISPENSER(S)

Refer to manual(s) provided with the Post–Mix

Dispenser(s) for installation instructions, then install

Dispenser(s) in operating location(s).

INSTALLING BEVERAGE CONTROL

PANEL ASSEMBLY

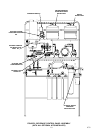

Your Beverage Control Panel Assembly may be

equipped with one or more of the optional kits as

shown in Figure 2. Figure 1 shows the standard

Beverage Control Panel Assembly with no optional

kits and Figure 2 shows the panel assembly with

optional kits installed.

NOTE: A dedicated and properly grounded

electrical outlet with proper electrical

requirements must be located close to the

Beverage Control Panel Assembly installation

location to provide electrical power to

(depending upon Beverage Control Panel Model

Number) one or two carbonators.

If your Beverage Control Panel Assembly is

equipped with either or both the optional air

compressor kit or the water pressure booster kit,

dedicated properly grounded electrical outlets with

proper electrical requirements must also be located

close to the Beverage Control Panel Assembly

installation location to provide electrical power.

No other electrical equipment should be connected to

these electrical circuits. ALL ELECTRICAL WIRING

MUST CONFORM TO NATIONAL AND LOCAL

ELECTRICAL CODES.

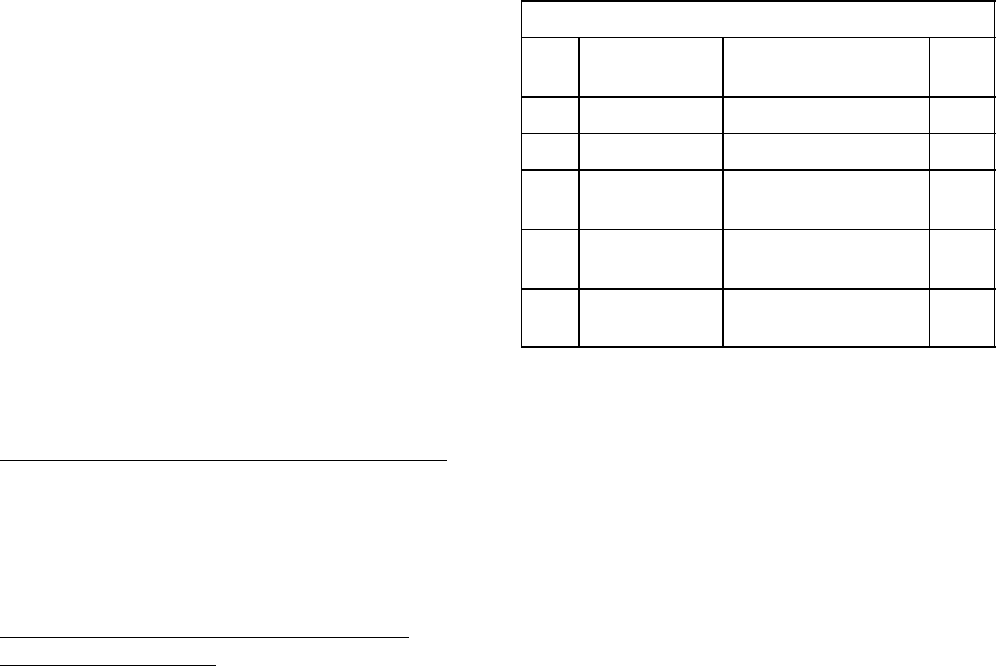

Table 2. Loose-Shipped Parts

Item

No. Part No. Name Qty.

1 300894–000 Water Surge Tank 1

2 300893–000 Strap, Surge Tank 1

3 300912 Tube Ass’y, .375 I.D.

By 56–in long

1

4 311304 Tapered Gasket,

Black

4

5 0590 Elbow Ass’y, Surge

Tank

1

INSTALLING WATER SURGE TANK (ITEM 1)

ON BEVERAGE CONTROL PANEL

ASSEMBLY

NOTE: It is suggested for ease of assembly, that

the loose–shipped WATER SURGE TANK (item 1)

be installed on the Beverage Control Panel

Assembly upper frame before the Panel

Assembly is set upright and fastened to the wall.

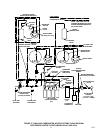

1. Install ELBOW ASS’Y SURGE TANK (item 5) in

top of WATER SURGE TANK (item 1) as shown

in Figure 17. Seal pipe thread connection with

pipe sealing compound.

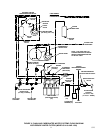

2. Refer to applicable Figure 1 or 2 for water surge

tank location on Beverage Control Panel

Assembly upper frame, then remove two

self–drilling screws from frame.

3. Position water surge tank in position on

Beverage Control Panel Assembly.

4. Place STRAP, SURGE TANK (item 2) in

position around water surge tank and align

holes in strap with holes in frame where two

self–drilling screws were removed.

5. Secure strap to frame with two self–drilling

screws removed in step 2) preceding.