5

0713

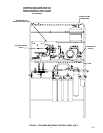

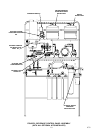

6. Connect one end of TUBE ASS’Y (item 33) to

water surge tank elbow assembly 3/8–inch flare

(5/8–18) fitting as shown in applicable Figure 3,

4, 5, or 6. Seal connection with TAPERED

GASKET, BLACK (item 4).

7. Connect other end of tube assembly to water

manifold assembly 3/8–inch flare (5/8–18) fitting

on water filter assembly (see applicable Figure

3, 4, 5, or 6). Seal connection with TAPERED

GASKET, BLACK (item 4).

FASTENING BEVERAGE CONTROL

PANEL ASSEMBLY TO WALL

WARNING: The Beverage Control

Panel Assembly must be securely

fastened to the wall before

connecting the assembly into the system.

The Beverage Control Panel Assembly must

be fastened to the wall with six fasteners

provided by the Installer) and each fastener

must be capable of resisting a 200 pound

(90.7 KG) pull. Be very careful when handling

the assembly as it is very top heavy and

could fall and cause serious personal injury

and also equipment damage.

Refer to instructions in previous WARNING note and

secure Beverage Control Panel Assembly to wall as

follows:

1. Very carefully, lay panel assembly upper frame

over on its back side. Slide telescoping lower

frame up on panel assembly upper frame.

2. Very carefully, lift Beverage Control Panel

Assembly up and place in position up against

wall.

3. Using screw adjusters on bottoms of Legs,

adjust until Control Panel Assembly sits level.

4. Secure Control Panel Assembly to wall with six

fasteners provided by the installer.

5. Using .156 I.D. tubing provided in installation kit,

connect one end of tubing to vented double

check valve (see applicable Figure 3, 4, 5, or 6),

then route other end of tubing to a permanent

floor drain.

6. Fasten tubing to frame assembly with wire ties

provided in installation kit.

CONNECTING SUGAR–BASE SYRUP TANKS

CO

2

LINES TO BEVERAGE CONTROL

PANEL ASSEMBLY CO

2

MANIFOLD

(see Figure 7)

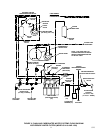

1. Using .265 I.D. tubing, fittings, gas quick

disconnects, and tubing clamps, provided in the

installation kit, make up three gas lines to be

connected between the CO

2

manifold and the

sugar–base syrup tanks.

2. Connect three gas lines swivel nut ends to CO

2

check valves on Beverage Control Panel

Assembly CO

2

manifold. Seal connections with

white tapered gaskets.

CONNECTING DIET SYRUP TANK CO

2

LINE

TO BEVERAGE CONTROL PANEL

ASSEMBLY DIET SYRUP CO

2

REGULATOR.

(see Figure 7)

3. Using .265 I.D. tubing, fittings, gas quick

disconnect, and tubing clamps, make up one

gas line to be connected between the Beverage

Control Panel Assembly diet–syrup tank.

4. Connect swivel nut end of gas line to check

valve on outlet of the diet–syrup tank CO

2

regulator. Seal connection with white tapered

gasket.

CONNECTING BEVERAGE CONTROL

PANEL ASSEMBLY TO POST–MIX

DISPENSER(S) AND OTHER EQUIPMENT TO

BE CONNECTED TO THE SYSTEM

(see Figure 7)

NOTE: The syrup, plain and carbonated water

and CO

2

lines to the Post–Mix Dispenser(s) and

various other equipment at the installation site

may be routed overhead or through a floor chase

from the Beverage Control Panel Assembly.

MAKE SURE ALL LINES ARE LABELED FOR

IDENTIFICATION.

Refer to manual(s) provided with the Post–Mix

Dispenser(s) to connect plain water, carbonated

water, and syrup lines to the Dispenser(s).

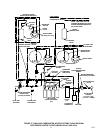

Center–Island Installation with Optional Syrup Tanks

Hookup (see Figure NO TAG)

Connect CO

2

, plain water, carbonated water, and

syrup lines between Beverage Control Panel

Assembly, the Post–Mix Dispenser, and other

equipment to be connected to the system. Optional

syrup tanks Kit (P/N 0673) is used to connect four

syrup tanks into system.

Connect insulated plain water line between plain

water line connected to Post–Mix Dispenser cold

plate and the Orange Juice Dispenser.