14

166240004

12/1/94

Rev 3/4/96

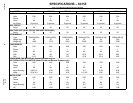

AIR-COOLED MODELS

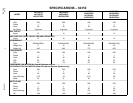

WATER-COOLED MODELS

Electrical Service

Line

Manual Disconnect

Switch

STRAIN RE-

LIEF

MUST BE

USED

Water Filter

Shut-Off

Valve

Dump

Valve

Drain Tube

Bin Drain

Tube

Floor

Drain

Electrical Service

Line

Manual Disconnect

Switch

Shut-Off Valve

Water Filter

Shut-Off Valve

Condenser Water Inlet

Dump Valve

Drain Tube

Floor

Drain

Bin Drain

Tube

Condenser Water

Drain Tube

Strain Relief

must be used

Note: Leave all panels on the cuber until it is in place on the bin.

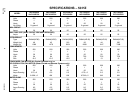

PLUMBING CONNECTIONS

1. All plumbing lines and connections must conform to local and

national plumbing codes.

2. Line shut-off valves must be located in supply water lines for cuber and condenser if product is water-

cooled. Water supply to water-cooled condenser must include a stand-pipe to prevent “water

hammer”.

3. Should your local water supply quality require the installation of a water filter system, consult your local dis-

tributor or dealer for proper size required.

4. Water supply pressure must not be lower than 20 PSI (1.37 BAR), nor should it exceed 120 PSI (8.16

BAR).

NOTE: Water filters larger then 5 microns do not give proper protection. Water pressures above 80

PSI (5.44 BAR) will destroy the filter.

DRAIN LINES: Bin and cuber drain lines must never be connected together and must be vented.

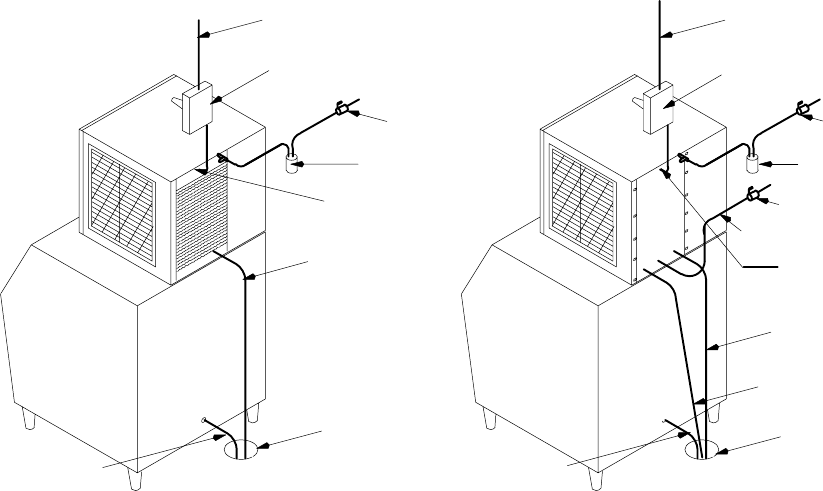

NOTE: All HP-62 (R404A) ice machines have a voltage range of –5%, +10% from the serial palte rating.

ELECTRICAL

1. All wiring and connections must conform to national and local electrical codes.

2. Wire size and circuit protection must conform to specifications and cuber must be on a separate electrical

circuit.

3. Strain relief connectors must be used at the junctions box of the control box and the cuber.

4. Cuber must be grounded by the control box ground screw or other method for intentional safety grounding

that meets code requirements.

5. A manual disconnect in a convenient location to the cuber must be installed.

INSTALLATION CHECK POINTS

1. Has bin and cuber been leveled and sanitized?

2. Does electrical and plumbing meet code requirements?

3. Check correct operating water level in the water pan.