30

166240004

12/1/94

Rev 3/4/96

A good vacuum is not always easy to measure, however the goal is to have less then 1% non-condensible va-

pors in the system at the completion of the evacuation. Basic guidelines with a good pump would be to evacu-

ate a selfcontained product 30 to 45 minutes and a remote product no less than 60 minutes.

The system should be evacuated to approximately 200/250 microns. Then perform a 5 minute holding test. You

may expect a low grade loss of the vacuum as normal. However, a rapid rise to normal atmospheric pressure

would signal a system leak is present and must be located and repaired before recharging the product. A slower

pressure rise to approximately 1500 microns would signal moisture still present in the refrigeration system.

On a “WET” system, it would be beneficial to use heat lamps to raise the temperature of the compressor dome

and evaporator surface area during the evacuation.

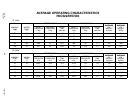

To assure a properly recharged product, the refrigerant charge must be weighed into the product using an elec-

tronic charging scale or dial-a-charge. On air- and water-cooled products the charge should be introduced into

the high side service valve. On remote systems, the charge should be introduced into the product receiver.

MANIFOLD SET

OPEN

OPEN

VACUUM

PUMP

ELECTRONIC

SCALE

CHARGING

CYLINDER

CLOSED

CLOSED

LOW SIDE

SERVICE

VA LV E

HIGH SIDE

SERVICE

VA LV E

OPEN

OPEN

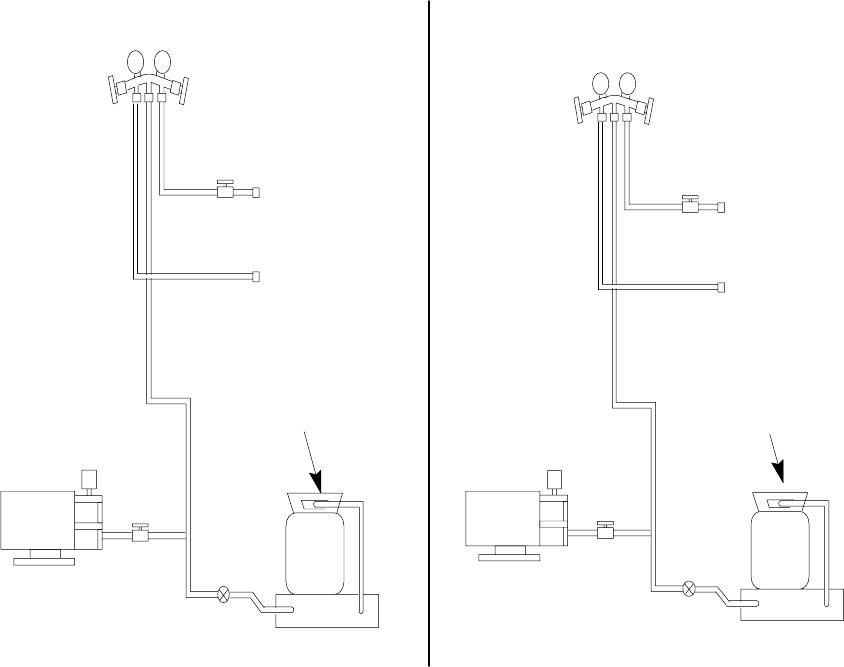

MANIFOLD SET

OPEN

VACUUM

PUMP

ELECTRONIC

SCALE

CHARGING

CYLINDER

CLOSED

CLOSED

LOW SIDE

SERVICE

VA LV E

HIGH SIDE

SERVICE

VA LV E

OPEN

OPEN

CLOSED

IMPORTANT: Service personnel are held responsible for ALL ASPECTS OF THE CLEAN AIR ACT OF

JULY, 1992.

REFRIGERANT DEFINITIONS

(ASHRAE 3-1990)

RECOVERY

To remove refrigerant in any condition from a system and store it in an external container without necessarily

testing or processing it in any way.

RECYCLING

To clean refrigerant for reuse by oil separation and single or multiple passes through devices, such as replace-

able core filter-driers, which reduce moisture, acidity, and particulate matter. This term usually applies to proce-

dures implemented at the field job site or at a local service shop.

RECLAIM

To reprocess refrigerant to new product specifications by means which may include distillation. Will require

chemical analysis of the refrigerant to determine that appropriate product specifications are met. This term usu-

ally implies the use of processes or procedures available only at a reprocessing or manufacturing facility.

NOTES REGARDING RECLAIM:

“New product specifications” currently means ARI standard 700-88. Note that chemical analysis is required to

assure that this standard is met.