Testing Procedures

!

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power and gas to range before servicing,

unless testing requires power and/or gas.

16 16026923

© 2006 Maytag Services

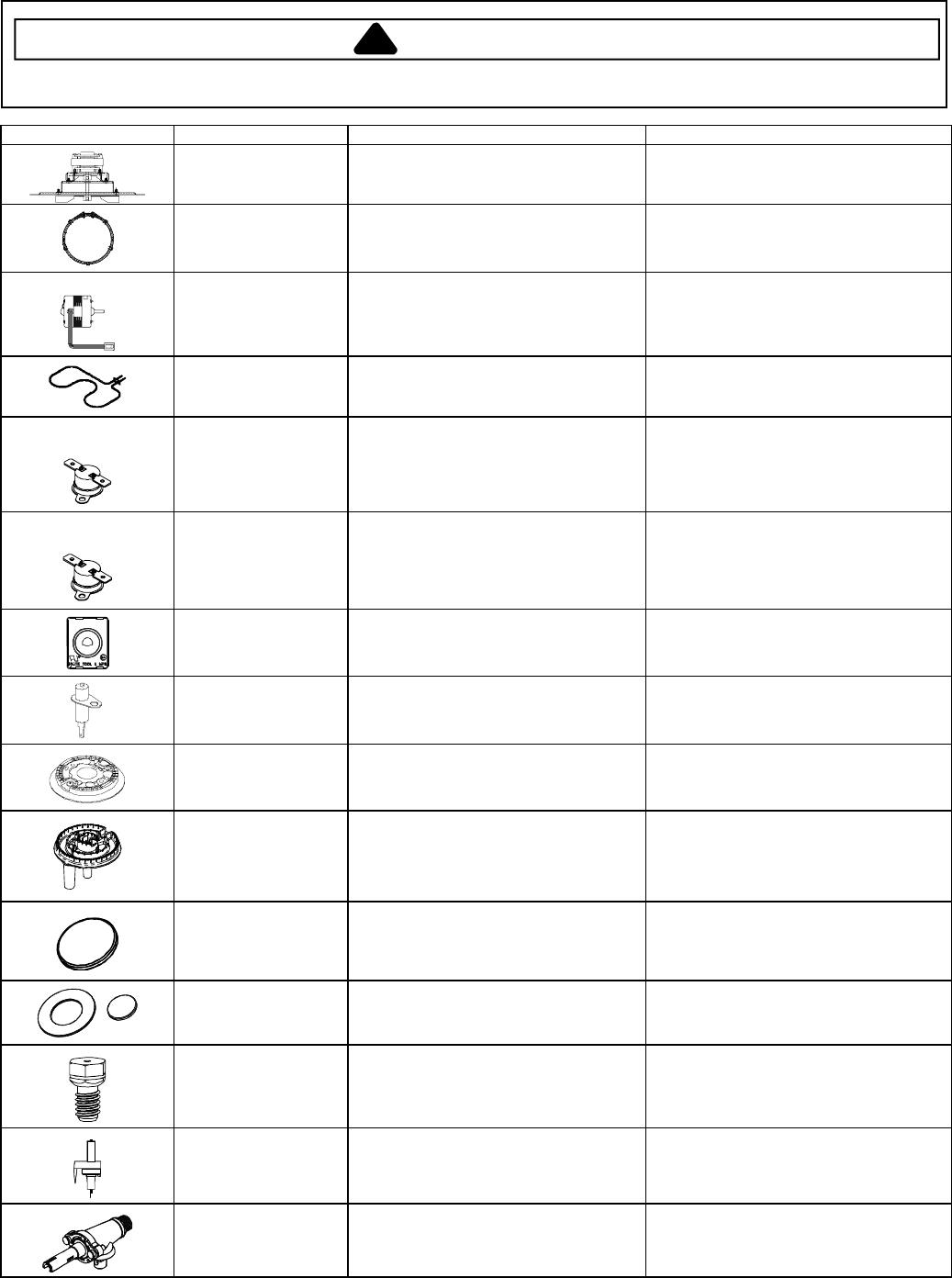

Illustration Component Test Procedure Results

Convection motor,

single speed

Measure voltage ......................................

Check motor windings to ground..............

120 VAC.

No continuity.

RPM:............ Approximately 900

Convection element Disconnect wiring to element and

measure cold resistance of terminals.......

Measure voltage at convect element........

Approximately 31 .

120 VAC.

JGS9900BD*

Downdraft motor Measure voltage ......................................

Check motor windings to ground..............

120 VAC.

No continuity.

RPM:............ Approximately 1550.

Warmer element Disconnect wiring to element and

measure cold resistance of terminals.......

Measure voltage at broil element .............

Approx. 12.5 to 18 .

120 VAC.

JGS8850BD*,

JGS8860BD*

Hi-limit temperature

switch

(Warming Drawer)

Normally closed, verify operation:

Open: 135° to 145° F (57° to 63° C).......

Closed: 114° to 126° F (46° to 52° C)....

Infinite.

Continuity.

JGS8850BD*,

JGS8860BD*

Hi-limit temperature

switch

(Warming Drawer)

Normally closed, verify operation:

Open: 95° to 105° F (35° to 41° C).........

Closed: 79° to 91° F (26° to 33° C)........

Infinite.

Continuity.

Spark switch Test for voltage at terminals.....................

Disconnect wiring and check for

continuity in LITE position ........................

120 VAC.

Continuity in LITE position.

Spark ignition

electrode

Test for resistance of spark lead..............

Test ignitor to chassis ..............................

Continuity.

No continuity from ignitor to chassis.

Top surface burner

5 K btu, 9.2 K btu

16 K btu

Verify gas is supplied...............................

Verify burner cap is positioned correctly...

Gas supplied.

Check for obstructions in burner ports.

Top surface,

dual ring burner

15 K btu

Inner: 3 K btu

Outer: 12 K btu

Verify gas is supplied...............................

Verify burner cap is positioned correctly...

Gas supplied.

Check for obstructions in burner ports.

Top surface,

burner cap

5 K btu, 9.2 K btu

16 K btu

Verify cap is positioned correctly.............. Check for obstructions in burner ports.

Top surface,

burner cap, dual ring

(inner and outer rings)

Verify cap is positioned correctly.............. Check for obstructions in burner ports.

Orifice Check for debris....................................... Clean as needed.

Orifice holder

5 K btu, 9.2 K btu

16 K btu

Verify gas pressure..................................

Check orifice for debris ............................

5" Natural.

10" LP/propane.

Clean as needed.

Burner valve,

push-to-turn, 270°

5 K btu, 9.2 K btu

16 K btu

Verify gas is supplied...............................

Orifice adjusted for Natural or LP.

Adjust set screw for simmer control.

Gas supplied.