37

Water Quality, Water Treatment and Freeze

Protection - see Appendix A

Filling Boiler With Water And Purging Air For

Systems With Diaphragm Type Expansion Tanks

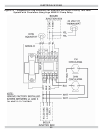

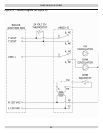

Refer to the appropriate diagrams, “Near Boiler Piping” on

page 11 for more information.

1.

Close all zone service valves on the supply and return

piping. Open the feed valve and fi ll boiler with water.

Make sure air vent is open. Hold relief valve open until

water runs air free for fi ve seconds to rapidly bleed air

from boiler, then let the relief valve snap shut.

2.

Open the zone service valve on the supply pipe for the

fi rst zone. Open the purge valve on the fi rst zone. Feed

water will fi ll the zone, pushing air out the purge valve.

Close the purge valve when the water runs air free.

Close the zone service valve.

3.

Repeat step 2 for all remaining zones.

4.

Open all service valves. Any air remaining trapped in

the return lines between the service valves and the

boiler will be pushed towards the air vent when the

boiler is placed in operation.

5.

Inspect piping system. Repair any leaks immediately.

Purging Air For Systems With Conventional

Closed Type Expansion Tanks:

Refer to the appropriate diagrams “Near Boiler Piping” on

page 11 for more information.

1.

Close all zone service valves on the supply and return

piping and close the expansion tank service valve.

Drain expansion tank. Open the feed valve and fi ll

boiler with water. Hold relief valve open until water

runs air free for fi ve seconds to rapidly bleed air from

boiler, then let the relief valve snap shut.

2.

Open the zone service valve on the supply pipe for the

fi rst zone. Open the purge valve on the fi rst zone. Feed

water will fi ll the zone, pushing air out the purge valve.

Close the purge valve when the water runs air free.

Close the zone service valve.

3.

Repeat step 2 for all remaining zones.

4.

Open the expansion tank service valve and the tank

vent. Fill the tank to the proper level and close the

tank vent. Remove the handle from the expansion tank

service valve so the homeowner doesn’t accidentally

close it.

5.

Open all service valves. Any air remaining trapped in

the return lines between the service valves and the

boiler will be pushed towards the expansion tank when

the boiler is placed in operation.

6.

Inspect piping system. Repair any leaks immediately.

START UP