Installation

13

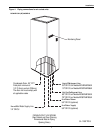

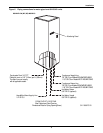

13. Smoke detector alarm connections. Field-supplied 24V. Class 1 wiring to remote alarm circuits.

Factory-wired contacts from optional smoke detector are #91 -comm., #92-NO, and #93-NC.

14. Common alarm connection. Field-supplied 24V. Class 1 wiring to common alarm terminals 75 +

76 (and optional 94 + 95, and 96 + 97), which are factory connected to common alarm relay (R3).

15. Heat rejection connection. Field-supplied 24V Class 1 wiring to interlock heat rejection from

pigtails 70 + 71 which are factory connected to compressor side switch (self-contained units only and

to GLYCOOL relay (R5), GLYCOOL units only).

16. Reheat and Humidifier Lockout. Optional emergency power lockout of reheat and/or humidifier:

connections provided for remote 24V AC source.

17. Main Fan Auxiliary Switch. Optional main fan auxiliary side switch. Terminals located in field

wiring compartment for remote indication that the evaporator fan motor/unit is on. Field to connect

24V maximum.

18. Optional Condensate Alarm (Dual Float Condensate Pump only). Relay terminals located in

field wiring compartment for remote indication.

*Located inside unit on top for Upflow and on base for Downflow.

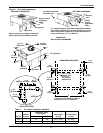

2.7 Balancing the Air Distribution

2.7.1 Under-Floor Discharge Systems

The systems are designed for constant air delivery, therefore any unusual restrictions within the air

circuit must be avoided. For under-floor air distribution, observe the following guidelines:

• Select the air supply grilles and perforated panels for the raised floor to ensure minimum loss of

pressure in the circuit. Air volume dampers on grilles, which extend several inches below the sur-

face of the raised floor, are usually detrimental to airflow.

• Consideration of the height of the damper on the grille in conjunction with the floor height will

determine whether this type of grille may be used.

• The grilles used in raised floors vary in size, the largest being approximately 18" x 6"

(457 x 152 mm). A larger grille size would be detrimental to the structural capacity of the raised

floor panel. An 18" x 6" (457 x 152 mm) heavy duty, pencil-proof type grille typically has 56 square

inches (0.036 m

2

) of free area.

• Perforated panels are available from various manufacturers of raised floors. These panels are

usually 2' x 2' (610 x 610 mm) square and have a nominal free area of approximately 108 to 144

square inches (0.07 to 0.09 m

2

). Use caution in selecting perforated panels as some manufacturers

have only 36 to 40 square inches (0.023 to 0.026 m

2

) of free area, requiring four times as many

panels.

• Avoid floor elevations below 7-1/2" (190.5 mm), loosely installed flooring systems, and below-floor

obstructions such as: electrical wiring chases, unusually long electronic system cables, or piping

clusters.

• Always check specifications of the floor supplier before specifying the total number of perforated

panels and grilles required to handle the air flow. The proper specifications for grilles and perfo-

rated panels should indicate the total free area required for air delivery rather than the number

of panels and grilles. (See Table 3 for recommended free area required for each model.) This table

indicates the recommended free area based on having the supply air grilles and perforated panels

sized to handle approximately 75% of the total cubic feet per minute (CFM) of the units at a veloc-

ity of 550 to 600 ft./min. (2.8 - 3.1 m/s). The remaining 25% of the air flow in the raised floor

passes through cable cutouts, cracks between the panels, and other leakage areas.

Table 3 Recommended free area ft

2

(m

2

) for grilles or perforated panels at output velocities of

550 and 600 fpm (2.8 and 3.1 m/s)

50 Hz Units 60 Hz Units

Model

550

FPM

2.8

m/s

600

FPM

3.1

m/s Model

550

FPM

2.8

m/s

600

FPM

3.1

m/s

3 Ton 2.5 (0.01) 2.3 (0.01) 3 Ton 2.5 (0.01) 2.3 (0.01)

5 Ton 3.5 (0.02) 3.3 (0.02) 5 Ton 3.8 (0.02) 3.5 (0.02)