Glycol/GLYCOOL Cooled Models

39

5.6 Condenser

The condenser is designed to operate in conjunction with a drycooler. The maximum coolant pressure

is 350 psig (2413 kPa).

5.7 Glycol Regulating Valve

The glycol regulating valve automatically regulates the amount of coolant necessary to remove the

heat from the refrigeration system, permitting more fluid to flow when load conditions are high and

less fluid to flow when load conditions are low. The valve consists of a brass body, balance spring,

valve seat, valve disc holders, capillary tube to discharge pressure, and adjusting screw.

5.7.1 Standard Valve - 150psig (1034kPa) System for 3 & 5 Ton Units (Johnson Controls Valve)

High Pressure Valve - 350psig (2413kPa) System for 5 Ton Units (Johnson Controls Valve)

For details, refer to 4.3.1 - Standard Valve - 150psig (1034kPa) System for 3 & 5 Ton Units

(Johnson Controls Valve) High Pressure Valve - 350psig (2413kPa) System for 5 Ton Units

(Johnson Controls Valve).

5.7.2 High Pressure Valve - 350 psig (2413 kPa) System for 3 Ton Units (Metrex Valve)

For details, refer to 4.3.2 - High Pressure Valve - 350 psig (2413 kPa) System for 3 Ton Units

(Metrex Valve).

5.7.3 Testing Valve Function

When the refrigeration system has been off for approximately 10-15 minutes, the coolant flow should

stop.

Should the coolant continue to flow, the valve is either improperly adjusted or the pressure sensing

capillary is not connected properly to the condenser.

NOTE

For pressures above 150 psig (1034 kPa), the high pressure option for high pressure valve(s)

is required.

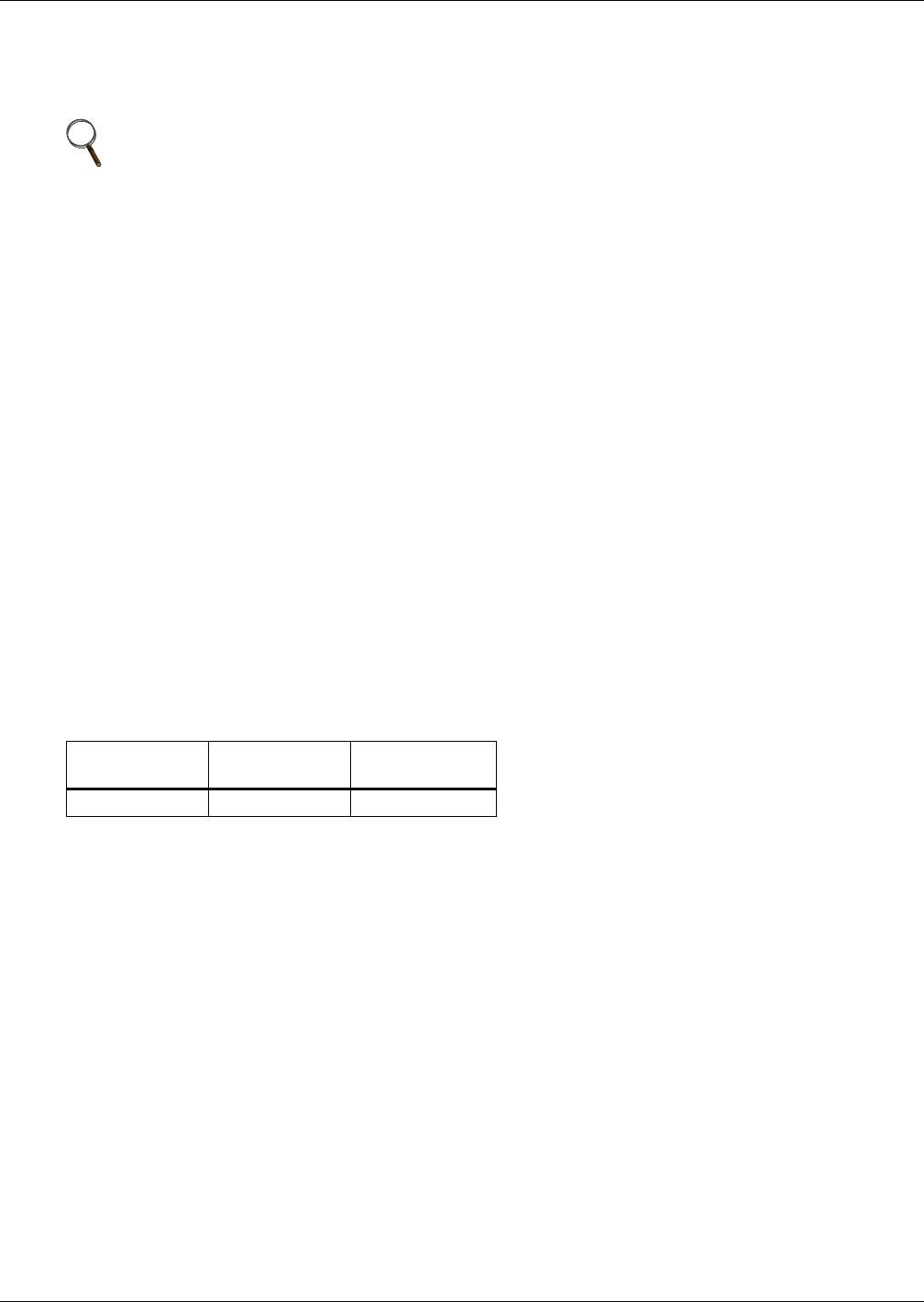

Table 20 Refrigerant control settings psi (kPa)

Low Pressure

Cut Out

Low Pressure

Cut In

High Pressure

Cut Out

20 (137.9) 65 (448.2) 360 (2482)