18

SECTION 2

INSTALLATION

II. VENTILATION GUIDELINES

A mechanically driven ventilation system is required for

the PS540 Series Middleby Marshall conveyorized elec-

tric ovens. The minimum hood canopy dimensions are

outlined below.

Local codes and conditions vary greatly from one area to

another and must be complied with. Following are the

suggested requirements for good ventilation. Please re-

member these are recommendations or guidelines, you

may have a special condition or problem that will require

the services of a ventilation engineer or specialist. Proper

ventilation is the oven owner’s responsibility. Improper

ventilation can inhibit oven performance. It is recom-

mended that the ventilation and duct work be checked out

every three months. Grease filters in the intake of the hood

may be required by local codes.

VENTILATION HOOD

The rate of air flow exhausted through the ventilation

system is generally between 1400 and 2500 cu. ft./min.

(40 and 70 m

3

/min), but may vary depending on the oven

configuration and hood design. To avoid a negative

pressure condition in the kitchen area, return air must be

brought back to replenish the air that was exhausted. A

negative pressure in the kitchen can cause heat related

problems to the oven components as if there were no

ventilation at all. The best method of supplying return air

is through the heating, ventilation and air conditioning

system. Through they system, the air can be temperature

controlled for summer and winter. Return air can be

brought in directly from outside the building, but detrimen-

tal affects can result from either extreme seasonal hot and

cold temperature from the outdoors.

NOTE: Return air from fan driven system within the hood

must not blow at opening of bake chamber or poor oven

baking performance will result.

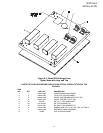

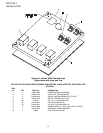

Figure 2-10. Vent Hood

1″ (25mm)

minimum

8″ (203mm)

minimum

18″

(458mm)

minimum

21-1/2″

(546mm)

minimum

2″ (51mm)

minimum.

To allow

stacking of

ovens.