22

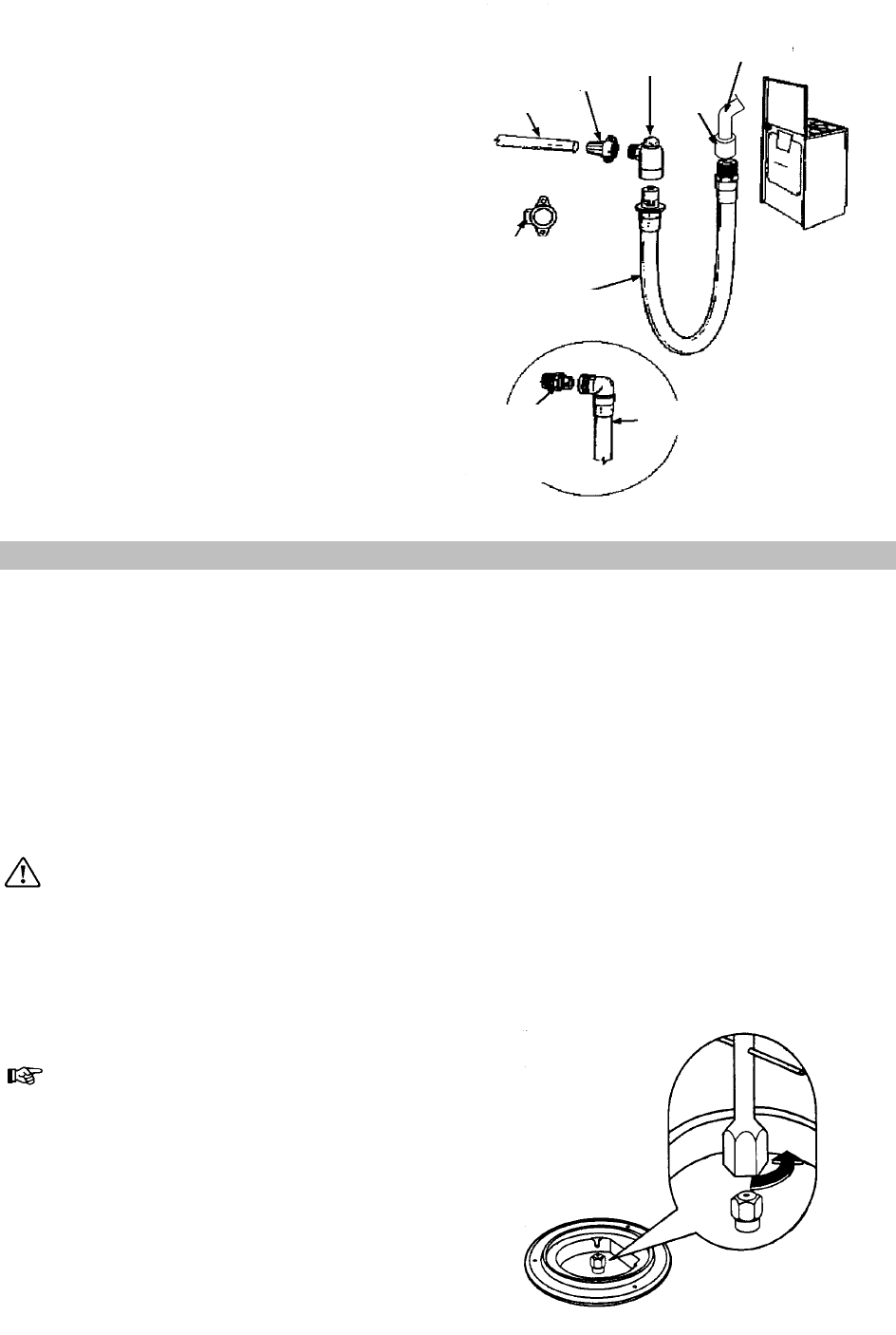

Connection shall be by means of an appliance

flexible connector for use with a self-sealing

plug-in device, complying with:

Flexible hoses, end fittings and sockets for

gas burning appliances – BS 669;

- The appliance flexible connector should not

be subjected to undue forces either in

normal use or whilst connected or

disconnected; The socket which the plug of

the appliance flexible connector fits should

be permanently attached to a firmly fixed

gas installation pipe and positioned such

that the appliance flexible connector hose

hangs freely downwards (see fig. 27);

- The appliance flexible connector should be

positioned such that it will not suffer

mechanical damage, e.g. abrasion from the

surrounding kitchen furniture, which may be

moved in use such as a drawer or door, or

by being trapped by any stability device.

The plug-in-connector should be accessible

for disconnection after moving the

appliance.

Straight bayonet

socket

incorporating

spring loaded

valve

Cooker hose with

bayonet fixing

Cooker hose with

bayonet fixing

Alternative

backplate

elbow

Copper pipe

Adaptor

backplate

Right angled

bayonet socket

incorporating

spring loaded

valve

Distribuitor

pipe

Female

elbow

CONVERSION OF GAS

Your cooker is designed to work with natural gas,

and is convertible for use with propane or butane.

The LPG conversion kit is available from your

Service Force Centre and must be fitted by a

Corgi Registered engineer.

For changing the gas type it is necessary to:

• replace the nozzles (hob, oven and grill);

• adjust the minimum level (hob and oven);

• adjust the primary air (oven and grill);

• check the gas connection;

Stick the label supplied with the

appliance (in the nozzles bag) corresponding

to the gas type utilised.

Replace the nozzles of the hob burners

Every appliance has spare nozzles for every type

of gas. The whole length of every nozzle is

marked in millimetres on the nozzle.

Hob burners

• Remove the pan support;

• Remove the caps and the burner crowns;

• Using a No 7 socket spanner unscrew the

nozzles and replace them with those required

for the type of gas in use (see table no. 1).

Reassemble the parts following the same

procedure in reverse.

These burners do not need any primary air

regulation.