PG14D: Floor Model Gas Pasta Cooker PREVENTATIVE MAINTENANCE

21

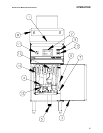

3.3.4. TANK

9 Verify that the tank is in good condition. Check for scale build up and inspect for signs of

corrosion. Verify that tank is leak free. Check drain overflow (if equipped) for scale build up

and debris blockage.

3.3.5. DRAIN SYSTEM

9 Verify that drain valve is in good condition. Check for leaks in the seal area and fitting region.

9 Verify that drain lines are leak free, kink free and in good condition. Check for scale build up

and debris blockage. Verify that the clamps and connections are securely tightened.

3.3.6. GAS COMBUSTION SYSTEM

9 Check for gas leaks.

9 Check and clean vent tube on gas valve pressure regulator.

9 Check burners, clean debris and grease from pilot and pilot orifice tips.

9 Check and adjust burner manifold gas pressure to nameplate reading.

9 Check incoming gas pressure when all gas appliances are on.

9 Check ignition system and adjust pilot flame as required.

9 Check flame sensor reading.

9 Recheck for gas leaks after inspection.

3.4. VENTILATION HOOD

Proper ventilation hood operation is very important for the correct operation of this appliance and the

safety of personnel. The ventilation hood should be inspected at the time of installation of this

appliance to insure that it will operate properly in conjunction with the appliance. A regular schedule

of examination, in accordance with ANSI/NFPA 96 latest edition and/or local codes must be followed.