FIG.

4

SHUT OFF VALVE HERE IF SHUT OFF VALVE HERE IF

REQUIRED BY LOCAL REGULATIONS

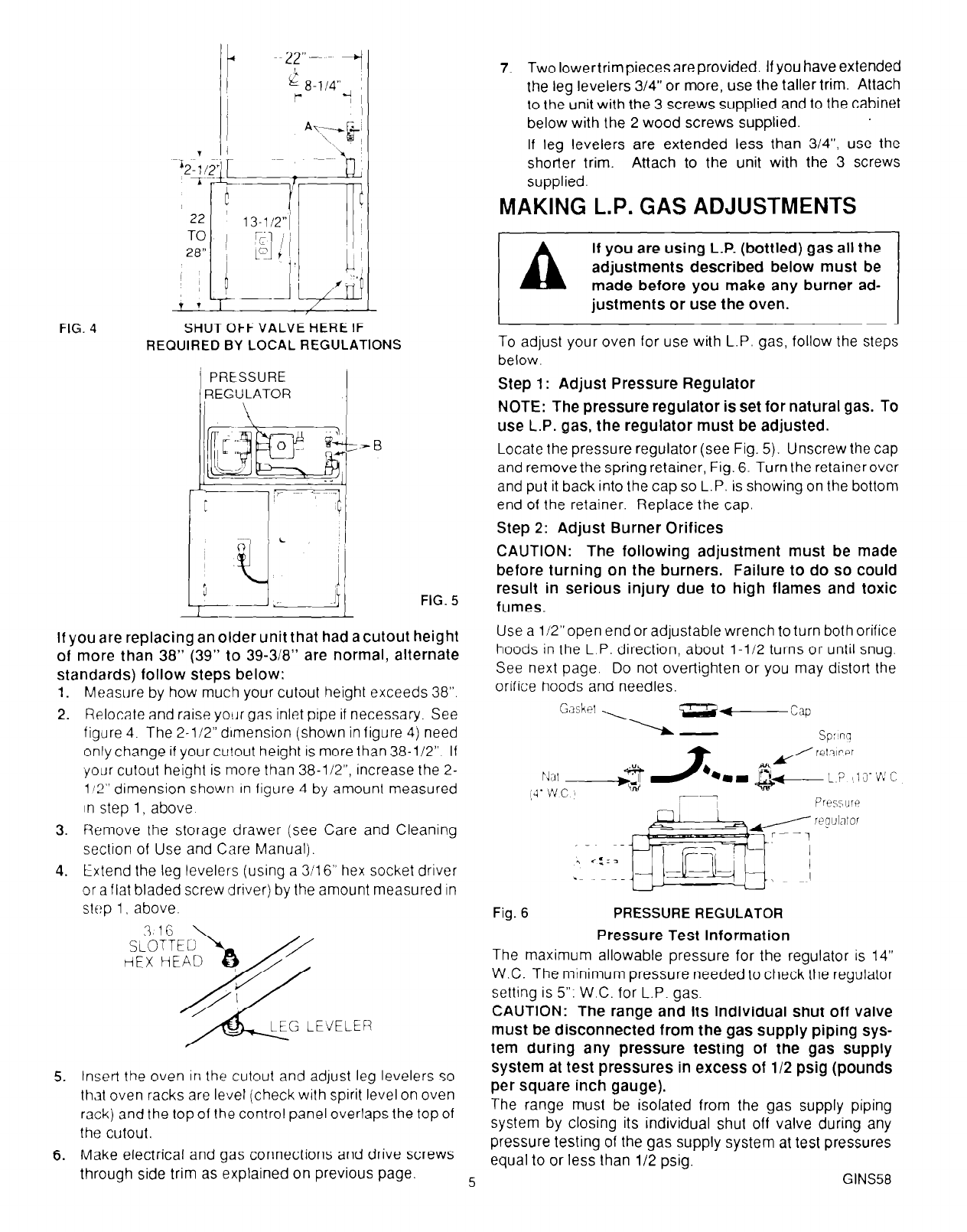

PRESSURE

REGULATOR

FIG. 5

If

you are replacing an older unit that had a cutout height

of more than 38” (39” to 39-318” are normal, alternate

standards) follow steps below:

1.

Measure by how much your cutout height exceeds 38”.

2. Relocate and raise your gas inlet pipe if necessary. See

figure 4. The 2-112” dimension (shown in figure 4) need

only change if yourcu!out height is more than 38-l/2”. If

‘your cutout height is more than 38-l/2”, increase the 2-

1’2” dimension shown In figure 4 by amount measured

in step 1 I above.

3. Remove the storage drawer (see Care and Cleaning

section of Use and Care Manual).

4. Extend the leg levelers (using a 3116” hex socket driver

or a flat bladed screw driver) by the amount measured in

step 1, above.

3.16 \

5. Insert the oven in the cutout and adjust leg levelers so

that oven racks are level (check with spirit level on oven

rack) and the top of the control panel overlaps the top of

the cutout.

6. Make electrical and gas connections and drive screws

through side trim as explained on previous page.

7.

TWO

lower trim pieces are provided. If you have extended

the leg levelers 34” or more, use the taller trim. Attach

to the unit with the 3 screws supplied and to the cabinet

below with the 2 wood screws supplied.

If leg levelers are extended less than 3/4”, use the

shorter trim. Attach to the unit with the 3 screws

supplied.

MAKING L.P. GAS ADJUSTMENTS

If you are using L.P. (bottled) gas all the

adjustments described below must be

made before you make any burner ad-

To adjust your oven for use with L.P. gas, follow the steps

below.

Step 1: Adjust Pressure Regulator

NOTE: The pressure regulator is set for natural gas. To

use L.P. gas, the regulator must be adjusted.

Locate the pressure regulator (see Fig. 5). Unscrew the cap

and remove the spring retainer, Fig. 6. Turn the retainer over

and put it back into the cap so L.P. is showing on the bottom

end of the retainer. Replace the cap.

Step 2: Adjust Burner Orifices

CAUTION:

The following adjustment must be made

before turning on the burners. Failure lo do so could

result in serious injury due to high flames and toxic

fumes.

Use a li2”open end or adjustable wrench to turn both orifice

hoods in the L.P. direction, about l-l/2 turns or until snug.

See next page. Do not over-tighten or you may distort the

orifice hoods and needles.

Fig. 6

PRESSURE REGULATOR

Pressure Test Information

The maximum allowable pressure for the regulator is 14”

W.C. The minimum pressure needed to check the regulator

setting is 5”: W.C. for L.P. gas.

CAUTION:

The range and its individual shut off valve

must be disconnected from the gas supply piping sys-

tem during any pressure testing of the gas supply

system at test pressures in excess of 112 psig (pounds

per square inch gauge).

The range must be isolated from the gas supply piping

system by closing its individual shut off valve during any

pressure testing of the gas supply system at test pressures

equal to or less than l/2 psig.

5

GINS58