2

2 - 15

W-2WAY ECO-i SYSTEM

Outdoor Unit Repair Procedures

7. Evacuating System

This procedure is carried out to ensure there is no remaining refrigerant or other gases (nitrogen, etc.) in the

repaired outdoor unit and tubing.

7-1. Evacuating Repaired Outdoor Unit

(1) Check that each service valve of the gas tubes, liquid tube, and balance tube in the outdoor unit are fully closed.

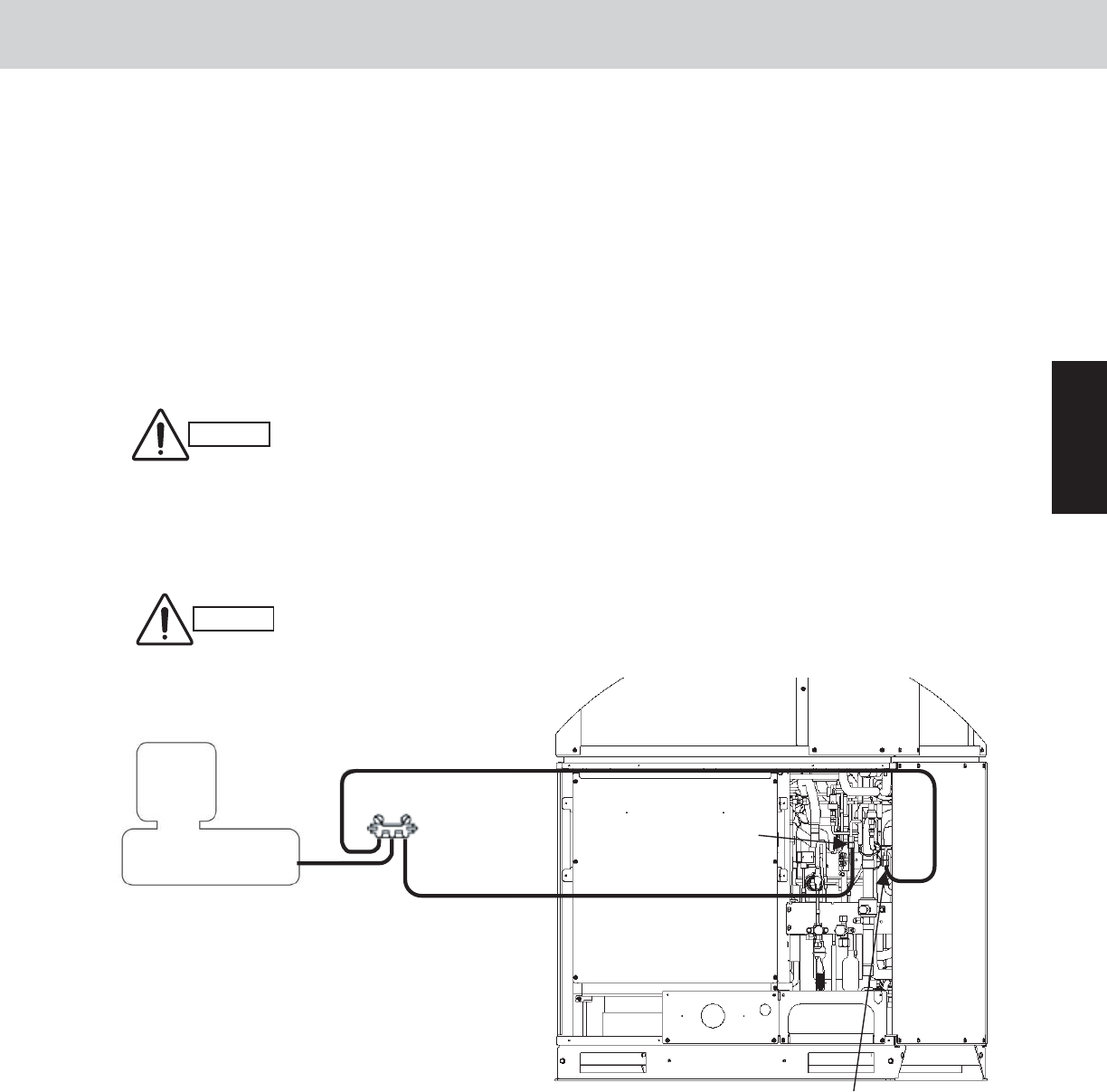

(2) Connect the manifold gauge valves to the high-pressure and low-pressure sensor outlets of the outdoor unit.

(Fig. 13)

(3) Connect the manifold gauge valves to the vacuum pump.

* If the AP pins (CN102) on the outdoor control PCB have already been short-circuited, step (4) is not neces-

sary.

(4) Turn off power to the repaired outdoor unit and short-circuit the AP (Air Purge) pins on the outdoor control PCB.

By short-circuiting the AP pins and turning on power to the outdoor unit, all elec-

tronic valves in the outdoor unit are forcibly opened and any remaining nitrogen

gas can be recovered. Failure to perform this procedure may result in nitrogen gas

remaining in the refrigerant circuit and causing operating problems. Therefore,

never skip this step.

(5) Turn the power ON at the outdoor unit where vacuum will be applied. Then run the vacuum pump and continue

evacuation until the vacuum condition falls to less than –14.7 psig (5 Torr).

To ensure proper evacuation, refer to the operating instructions that came with the

vacuum pump.

7-2. Evacuating Refrigerant Tubing Between Indoor and Outdoor Units

Refer to the “Installation Instructions” that came with the outdoor unit.

CAUTION

CAUTION

Fig. 13

Lo Hi

Manifold

gauge

High-pressure outlet port

(For 5/16" (7.94mm)-dia.

connector)

Vacuum pump

Low-pressure outlet port

(For 5/16" (7.94mm)-dia. connector)